Fig. 2 fig. 3, Fig. 4 fig. 5 – Clarus Environmental Turbine STEP Systems User Manual

Page 4

4

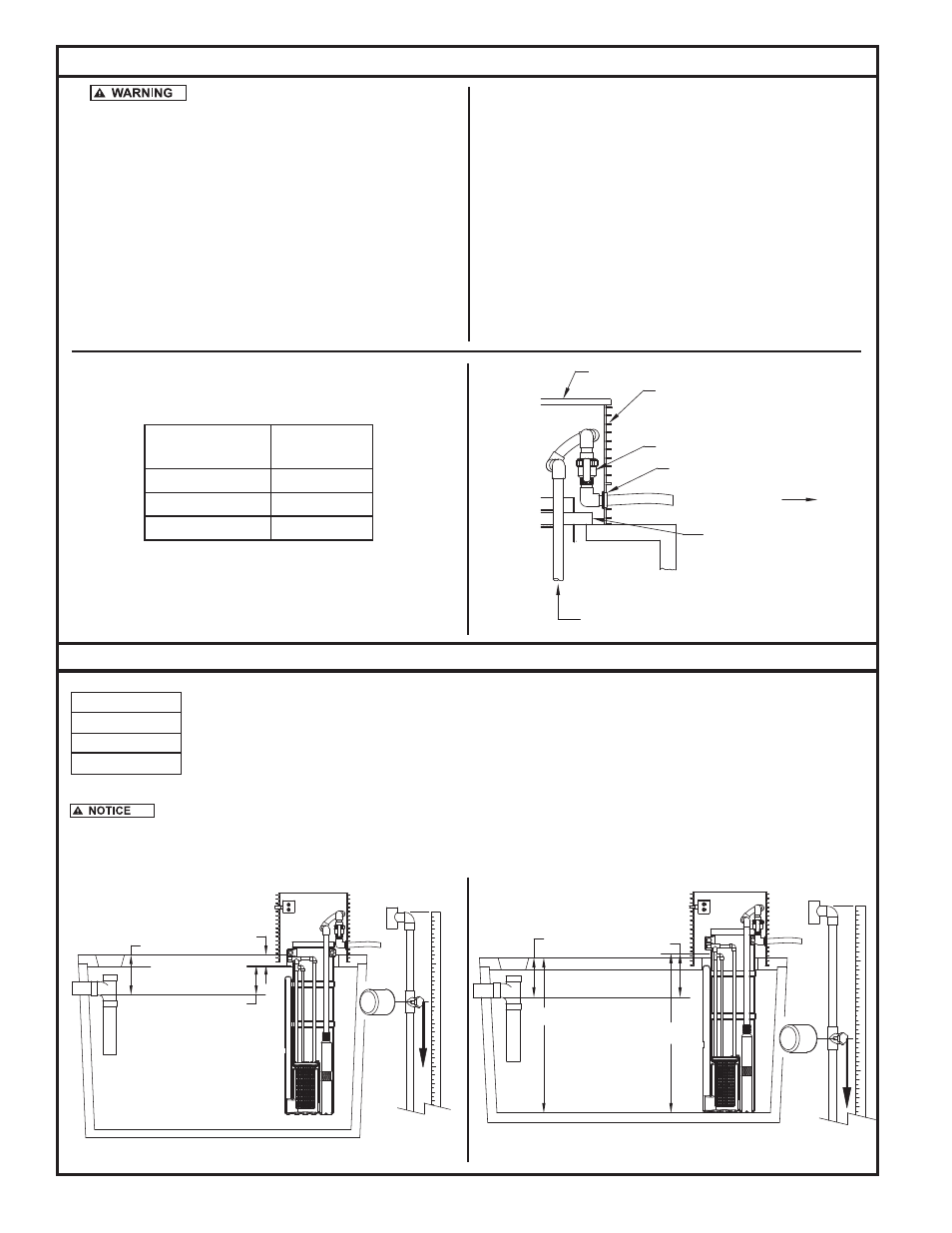

SINGLE UNION BALL VALVE

FILTERED EFFLUENT

PIPE SEAL

CLARUS ACCESS RISER (24" SHOWN)

LID

FROM PUMP

HANGER PIPE

DISCHARGE

Do not lower the pump by the power cord.

10. If supplied or required, attach the check valve to the pump outlet.

Disconnect the Clarus Environmental flexible pipe discharge as-

sembly at the union on the ball valve. Connect the long part of the

discharge assembly to the pump outlet or check valve with the pump

set up outside the pump vault. If check valve is used, weephole

should be below check valve.

11. Tie off the power cord by strapping it to the upper end of the discharge

pipe. Make certain the cord cannot become entangled or obstruct

the movement of the floats. Lower the pump by the discharge pipe

into the right or left pump well of the pump vault (see Fig. 1).

SK1833

Fig. 2

Fig. 3

DISCHARGE PIPE

ASSEMBLY

HOLE SAW

REQUIRED

1"

1¾"

1¼"

2"

2"

3"

Top of septic tank to liquid level (bottom of outlet).

Top of septic tank to bottom of inlet.

Top of septic tank to inside floor

STEP system pump vault inlet height (to the center of the inlet).

13"

52 1/2"

51"

EXAMPLE:

51 - 13 = 38

52 1/2 - 38 = 14 1/2

(SO THE ALARM FLOAT SHOULD

BE SET LOWER THAN 14 1/2"

FROM THE TOP OF THE FLOAT

ROD)

11

10

9

8

7

5

4

3

2

6

18

17

19

13

14

15

16

1

1

12

21

20

22

14 1/2

TOP OF THE FLOAT TREE

14"

3 1/2"

EXAMPLE:

14 - 3 1/2 = 10 1/2

(SO THE ALARM FLOAT SHOULD

BE SET LOWER THAN 10 1/2"

FROM THE TOP OF THE FLOAT

ROD)

10 1/2"

22

21

20

19

18

17

6

11

16

15

14

13

12 1

7

8

9

10

1

2

3

4

5

TOP OF THE FLOAT TREE

Fig. 4

Fig. 5

SK2435A

SK2435B

Discharge Pipe and Pump Installation

Float Tree Assembly

The alarm must be activated at or before the point when the effluent level reaches the bottom of the inlet pipe. If the STEP

system is being installed in an existing septic tank, the outlet pipe must be plugged.

12. Reconnect the union loosely to see approximately where to install the

pipe seal through the riser wall. Remove the pump by the discharge

assembly. Drill the appropriate hole through the riser wall (see Fig.

2). Install the pipe seal through the riser wall to prevent ground

water intrusion. Disconnect the union on the discharge assembly

and install the flexible pipe through the pipe seal with the union

ball valve on the inside of the riser (see Fig. 3). Solvent weld the

flexible pipe to the lateral field piping using PVC pipe cement.

13. Lower the pump by the discharge assembly back into the appropriate

pump well in the pump vault. Adjust the piping using the threaded

elbows and flexible piping of the discharge assembly to achieve

proper fit. Securely connect the union on the ball valve. Repeat

steps 9-12 for a second pump in a dual pump system.

© Copyright 2011. All rights reserved.