Barranca Diamond GP-6 Cabmaker User Manual

Page 26

26

BELT

The GP-6 Cabmaker arbor is driven from the electric motor by a AX-24 rubber belt. The belt tension

is adjusted at the factory. However, if it is necessary to service this belt, unplug the GP-6 Cabmaker

from its power source and remove the fasteners that secure the belt guard housing to the motor. The

belt tension should be checked periodically by removing the guard and depressing the belt in the

middle between both the motor and blade arbor 2" OD pulleys. There should be 1/2" of deflection

when the belt is pushed down (Fig 43). If the belt tension should become loose, poor performance or

slipping will result. If the belt is too tight (i.e. no deflection) the belt, electric motor, pulleys and blade

arbor bearings may wear out prematurely or the motor may overheat and shut off. Belt tension can be

adjusted by loosening the two mounting bolts attached to the base of the motor mount and sliding the

motor cradle base forward or backward to increase or decrease belt tension. Be sure to adequately

retighten the motor mount nuts and replace and attach the belt guard to the table as well.

ARBOR ASSEMBLY

The GP-6 Cabmaker is equipped with a 5/8" OD arbor shaft, two rubber sealed ball bearings and a

2" OD x 5/8" bore die cast zinc coated pulley. Should the bearings wear out on the arbor shaft, grind-

ing and polishing performance and short diamond wheel/belt life may result. Additionally, premature

bearing wear may result in permanent damage to the arbor shaft, bearings, belt and motor. This main

stainless steel shaft arbor assembly can be purchased from Barranca Diamond as a complete unit.

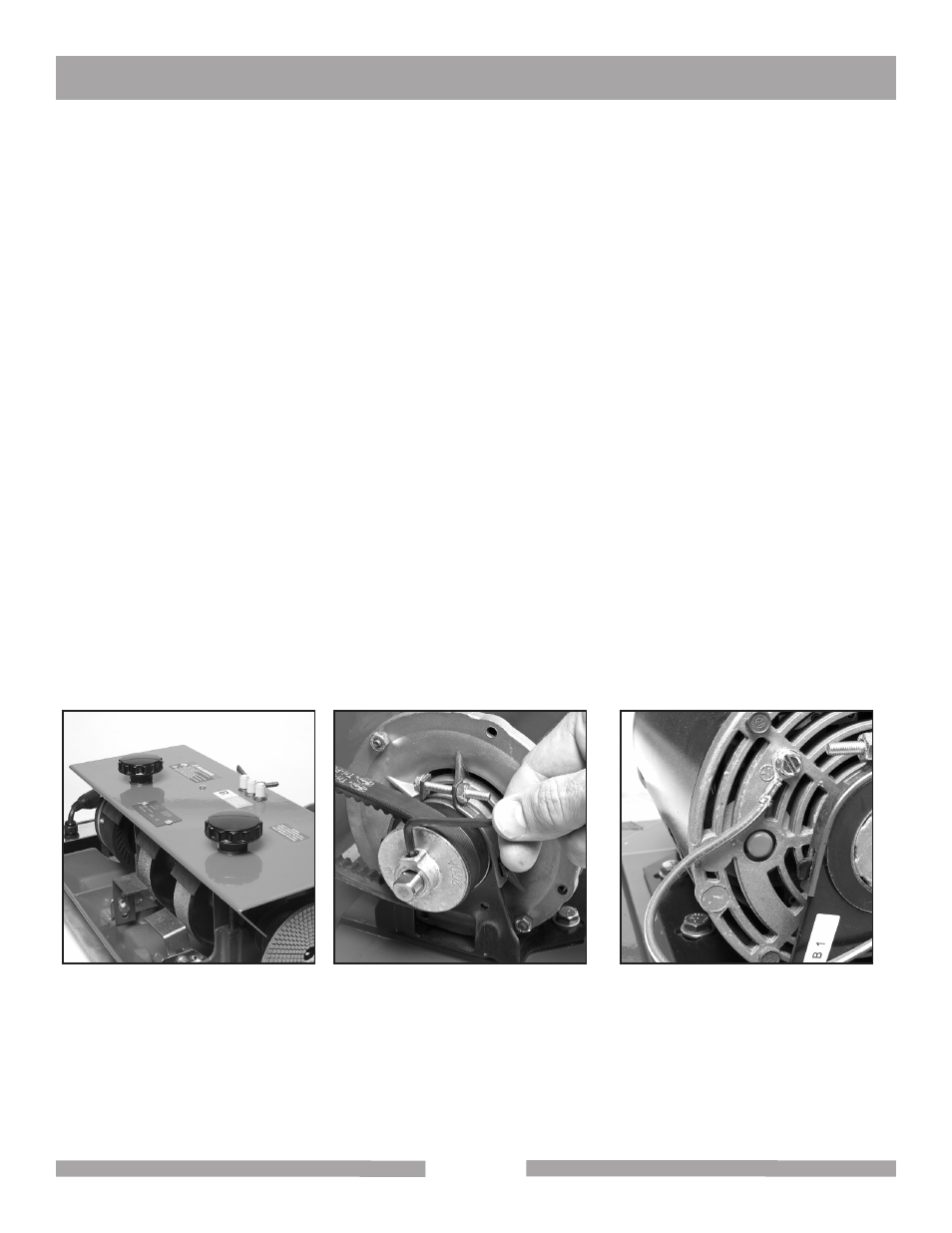

Periodically check the tightness of the hood attachment knobs (Fig 44) to make sure they are secure-

ly tightened to the aluminum body of the GP-6 Cabmaker. Should the 2" OD die cast pulleys on either

the motor (Fig 45) or wheel arbor shaft need to be removed or replaced, loosen the setscrew on the

hub of each pulley with a US standard Allen type wrench. The setscrews can be secured with liquid

thread locker (removable type) to prevent loosening due to vibration.

Fig 44 - Hood attachment knobs.

Fig 45 - Motor arbor shaft pulley.

Fig 46 - Motor reset button.

ELECTRIC MOTOR

The GP-6 Cabmaker is equipped with a Baldor 1/3 HP 1725 RPM single-phase 120 volt 60 Hz 8 amp

motor. The motor shaft has sealed ball bearings and requires no lubrication. The motor is protected

from thermal damage (overheating) with an automatic shut-off switch. If the motor overheats it will

automatically shut off and restart once its internal components cool down and the motor is restarted

GP-6 CABMAKER

MAINTENANCE