Barranca Diamond GP-6 Cabmaker User Manual

Page 14

14

PUMP SET-UP (continued)

Keep the water hose away from the electric motor and belt guard to prevent damage from moving

parts and electric shock hazard. The pump should always be used with clear, clean water so as to

avoid grit/abrasive material, mud or rock fragments from scratching the gemstones during polishing or

clogging the pump valves. For optimal water flow, adjust both the pump and the brass intake valve to

their fully open positions. Should less water be desired, turn the brass lever on the inlet valve to restrict

flow to the hood (Fig 12).

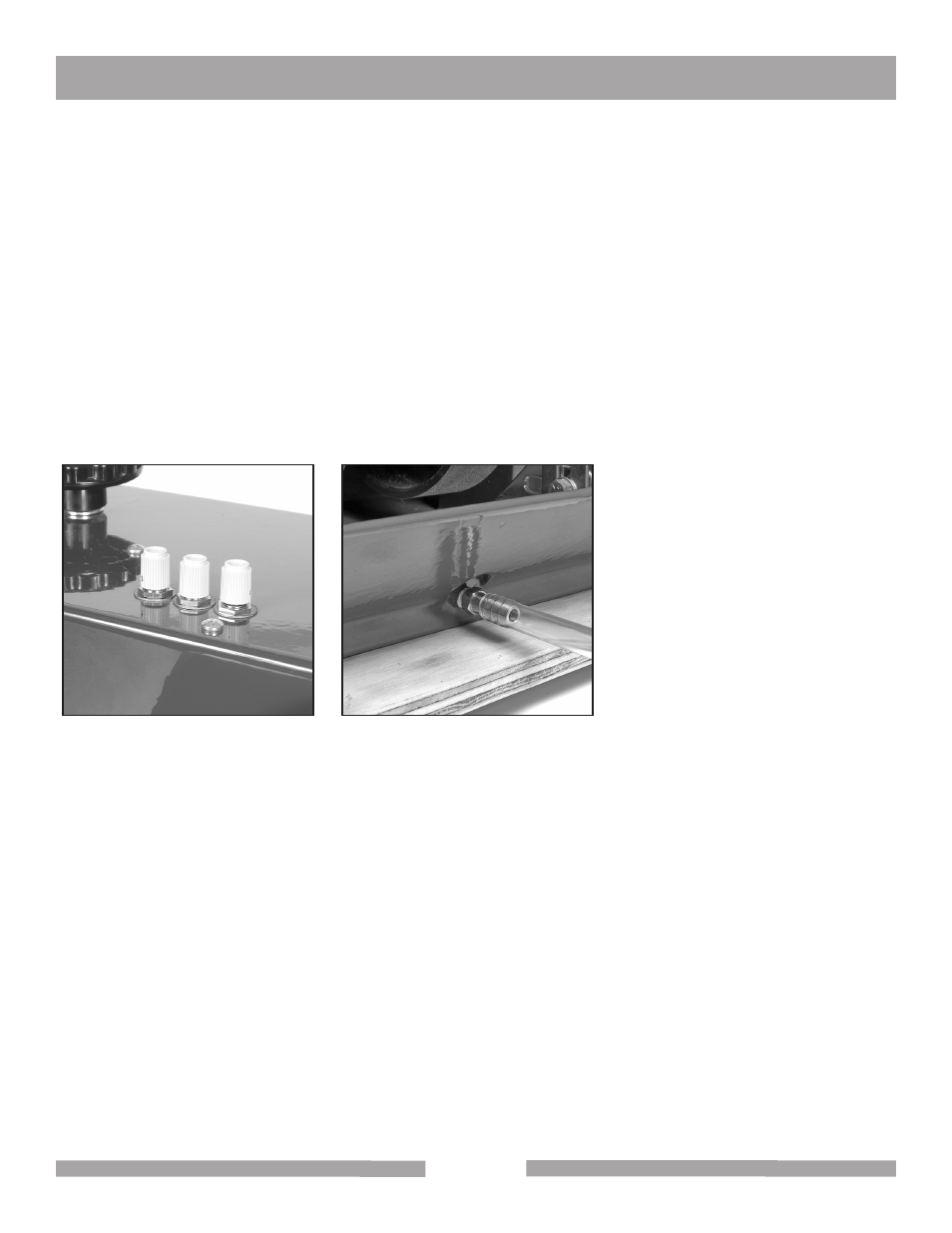

NEEDLE VALVES

The three stainless needle valves (Fig 14) are for fine control of water to each of the three grinding

and polishing stations. For best results, close the valves to the stations not in use. To shut off flow to

a needle valve, simply turn the grey ribbed knob clockwise until it closes to a firm stop (do not over-

tighten). To open maximum flow to a needle valve, simply turn the grey ribbed knob counterclockwise

until the valve stops. It may take up to 30 seconds for water flow rate to change to a specific station.

Fig 14 - The three stainless needle

valves

Fig 15 - Drain with hose installed

DRAIN VALVES

A length of 3/8" ID tubing is provided with the GP-6 Cabmaker for drainage of excess water from the

front base of the reservoir where a drain is located at the base of the reservoir (Fig 15).

To drain off the excess build-up of cooling water on the diamond wheels and expandable drum belts,

connect length of 3/8" ID clear tubing to the drain and route it into a 5 gallon collection bucket or drain

for dirty water.

Do not recycle dirty water from the drain valves into a collection bucket for pumping back up to the

intake valve on the rear of the hood as the contaminants (rock grit, mud, slurry and abrasive particles)

will likely scratch the gemstone material being worked and possibly clog the stainless steel water con-

trol valves or submersible pump.

GP-6 CABMAKER

OPERATION AND ADJUSTMENT