Flame and burner adjustments – Bakers Pride 616 Manual User Manual

Page 14

14

FLAME AND BURNER ADJUSTMENTS

GAS PRESSURE ADJUSTMENTS

Baker’s Pride ovens are equipped with fixed sized ori-

fices. Adjustments can not be made to the orifice.

Gas flow and pressure is to be checked at installation.

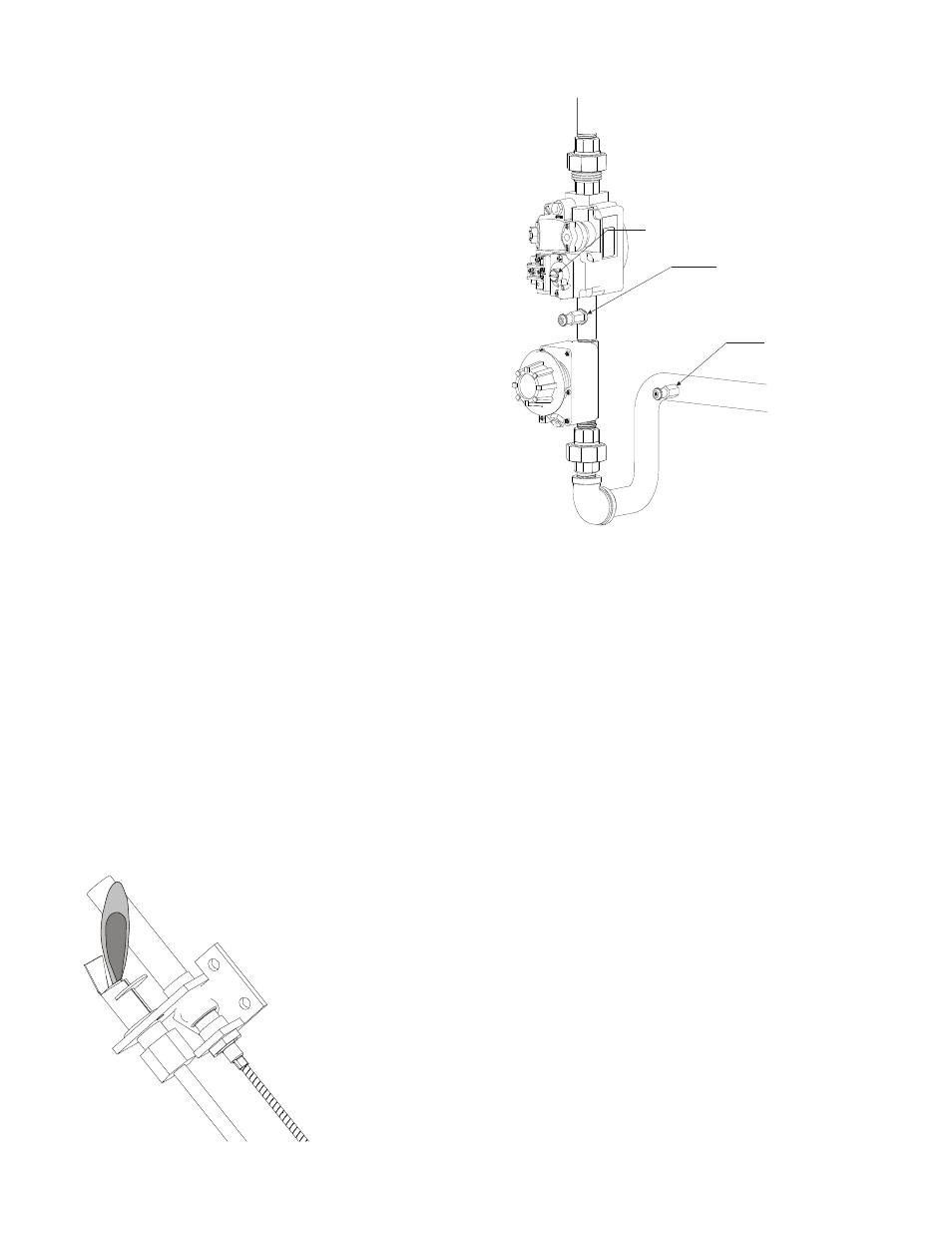

A pressure tap is supplied with each oven. It is located

in the control compartment along the gas supply piping.

On older models this tap will be along the manifold

pipe or fittings. On newer models the pressure tap will

be located between the gas valve and thermostat.

Gas supply pressure must match the oven’s rating plate.

This value must be checked with the oven and all other

appliances on the same gas supply line running at their

highest burner setting.

Connect a manometer to the pressure tap and check the

gas pressure while the burners are running at their high-

est setting. Ovens equipped with a 7000 combination

valve have an adjustment screw on the front of the valve. Ovens equipped with a pilot safety valve will

have a traditional regulator in the gas line before the valve.

This adjustment is originally made at the factory prior to shipment. However, it must be re-checked

and/or adjusted at installation to match your gas supply. This adjustment is not covered by warranty.

PILOT LIGHTING AND ADJUSTMENTS

Most ovens have a combination valve that supplies gas to the pilot burner. Some ovens have a pilot

safety valve. The basic method is the same for each.

The 7000 combination valve has a dial that controls the gas flow. Turn it to “PILOT”. The pilot safety

valve has a RED button.

Turn the gas supply to the oven ON.

Slightly depress and turn the combination gas cock knob to the PILOT position.

Depress the dial or the red button and hold. It may take several minutes to bleed air from the tubing

supplying gas to the pilot burner.

Apply a flame to the pilot burner to light. Continue to hold the dial/button depressed for at least 30

seconds for the flame to be sensed by the valve.

After letting go of the dial/button if the pilot flame goes out repeat the

above steps.

Once the flame is lit and burning normally for several minutes to insure

all air is bled from the supply tube the flame may need to be adjusted.

On pilot safety valves there is an adjustment screw above the red button.

On combination valves there is an adjustment screw at the top left corner

of the valve body. Remove the pilot adjustment cap.

Using a small flat blade screwdriver turn the screw counter-clockwise to

reduce the size of the flame. Turn the screw clockwise to increase the

size of the flame. The flame should be approximately 3/8 in to 1/2 in

high and wrap around the flame sensor bulb.

NEWER

LOCATION

TRADITIONAL

LOCATION

ADJUSTMENT

SCREW