Turning the expander on or off, Connecting to the idr-8, Connectors and grounding – Allen&Heath iDR-Switch User Manual

Page 2: Link power

2

IDR-switch User Guide AP5141

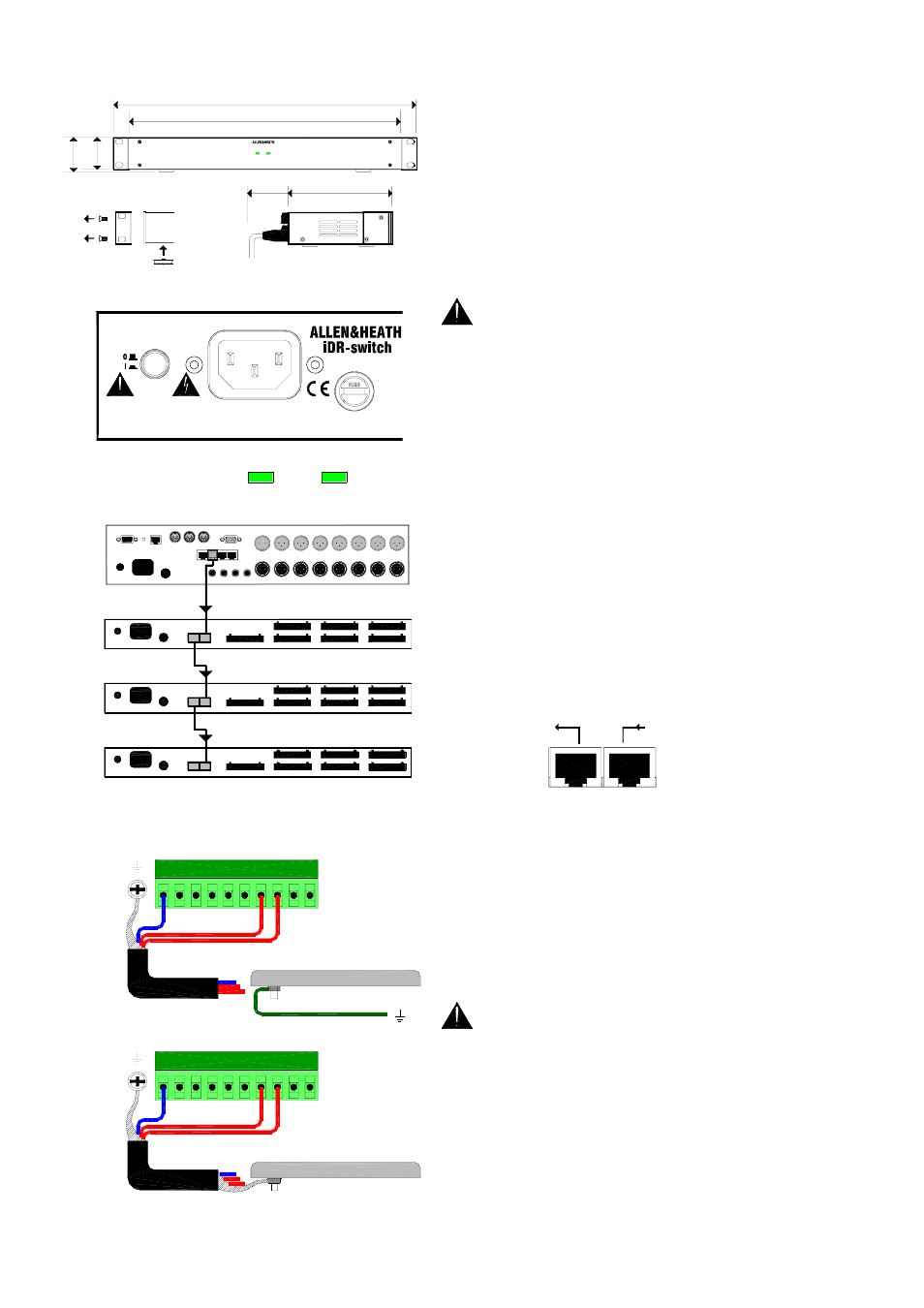

The iDR-switch can be rack mounted or free standing. There

are no user controls on the front panel. Allow a minimum of

65mm clearance behind the unit for the connectors and cables.

Ensure adequate ventilation to the side of and behind the unit.

It is shipped with its rack ears fitted and its feet removed ready

to be mounted in a standard 19” equipment rack. 1U rack

space is required. For desk mount operation remove the two

rack ears using a Torx (star head) T10 screwdriver. Fit the four

plastic feet provided by pressing them into the underside.

Make sure you have read the Safety Instructions

Sheet AP3345 which comes with the unit. Check that your

local mains supply is compatible with that printed on the

rear panel of the unit. Ensure that the correct mains lead

with moulded plug and IEC connector has been supplied.

For your own safety and optimum performance make sure

the system is correctly grounded.

Turning the expander on or off

Turn the unit on

by pressing the rear panel power ON/OFF switch. The power

LED lights up. The link LED lights if the DR-Link connection is

established with the iDR-8.

Connecting to the iDR-8

The iDR-8 communicates

with the iDR-switch using the DR-Link port. This serial

connection can be daisy chained through the 3 switch units as

shown, and then on to the iDR-in and iDR-out expanders if

fitted. Make sure you plug the DR-Link IN and OUT sockets

correctly. Use CAT5 STP cables with RJ45 connectors. Do not

use UTP cable. A standard 2 metre cable is provided with each

unit. You can use cables up to 300 metres long between units

for remote positioning. Ensure a good mains supply and solid

grounding to each unit.

Connectors and grounding

Pluggable Phoenix

type screw terminal connectors are used for connecting the

external switches and logic to the iDR-switch. Mating plugs

are provided with the unit. Make sure the wire ends are

carefully stripped and inserted into the terminals. Tighten the

screws using the correct slotted screwdriver. To ensure

interference-free operation use shielded cable. Connect the

shields to the chassis ground screw terminals provided next to

each connector. Fit the screws with the shake proof washers

provided.

For operator safety make sure that wall plates and

other control surfaces made from metal are correctly

bonded to ground (earth).

Strap the metal plate to the local ground at the wall box. For

ground isolation between the wall plate and equipment rack

connect the cable shield at the iDR-switch end only.

If a local ground is not available then use the cable shield to

connect the plate to the chassis of the iDR-switch unit as

shown. This is not necessary if the wall plate is made of non-

conductive material such as plastic which insulates it from the

operator.

SWITCH 49-72 OUT 33-48

DR-Link

SWITCH 1-24 OUT 1-16

SWITCH 25-48 OUT 17-32

G

METAL WALLPLATE

CHASSIS EARTH

G

METAL WALLPLATE

LOCAL EARTH BOND

link

power

FUSE: T500mAL

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

100 - 240V~

47-63Hz ~ 15W MAX

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN. AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

OUT

IN

DR-LINK

next

previous

link

power

24 IN 16 OUT SWITCH CONTROLLER

iDR-switch

144mm

5.7"

209mm

8.2"

65mm

2.6"

48mm

1.9"

44mm

1.7"

1U

Remove 2x rack ears

Fit 4x feet

M3 Torx T10

483mm

19"

443mm

17.4"

iDR-switch