ACU-RITE ENC 125 T/E User Manual

Page 11

These steps apply to typical encoder mounting conditions and

assumes the mounting surface is parallel to the machine

travel to within .010”.

• Acu-Rite Companies Inc. bracket kit instructions supercede

this section.

• Adjust drill depths and fastener lengths as required.

• Contact your authorized Distributor should you require

additional assistance.

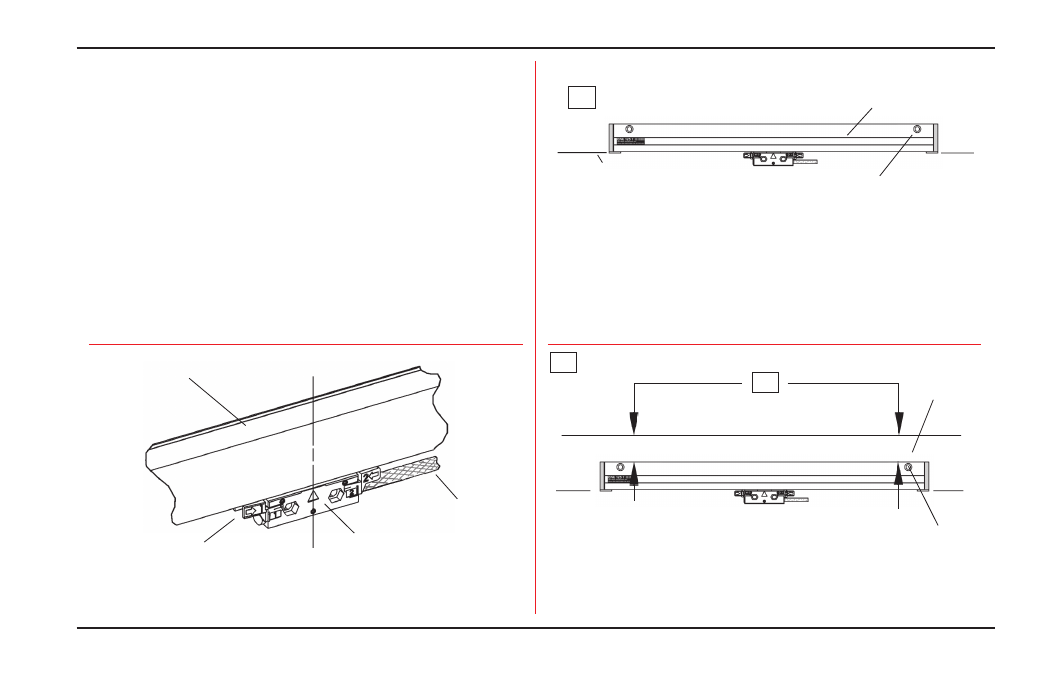

• Move the reading head to the center of the scale case by

sliding the reading head and brackets along the case.

• Move the machine axis to its center of travel and mark the

axis for future reference.

• Locate the encoder so that a suitable mounting position is

provided for both the scale case and the reading head.

Keep the underside of end caps approximately flush with

the underside of the table (or axis parting line).

• Mark the location of one end mounting hole to the

mounting surface and remove encoder.

9

Acu-Rite Companies Inc.

ENC 125 T/E

Encoder Installation Procedure

Scale case

Reading head assembly

Alignment brackets (2)

CL

Center mounting axis

Align top of scale case to

within .015” of -A-

Cable assembly

Scale case

Axis parting line

End mounting hole (typical)

• Drill & tap the first end mounting hole location.

• Attach the encoder and align to within .010” TIR. to -A-.

• Transfer punch the remaining mounting holes and remove

the encoder.

10-32 x1-1/4” SHCS & M5 flat washer

Align to within .010” TIR to -A-

-A-

Drill / tap

for 10-32

-A- = Axis travel

-A- = Axis travel