3 hydrostatic pump troubleshooting, 2 hydraulic feed maintenance – Echo 72928 Owners Manual v.4 User Manual

Page 24

21

S

E C T I O N

3

Tension drive belt (replace if

necessary).

Refill reservoir. Purge air from

transmission if necessary.

Drain fluid from reservoir and

unit, replace filter element,

and refill with new fluid.

Check relief pressure in sys-

tem with a pressure gauge

rated to 2500 psi. (System set

by factory at 1750 psi.)

Repair or reconnect control

linkage.

Repair drive (replace broken

belt, repair sheared key, re-

pair splined coupling, etc.).

Refill reservoir. Purge air from

transmission.

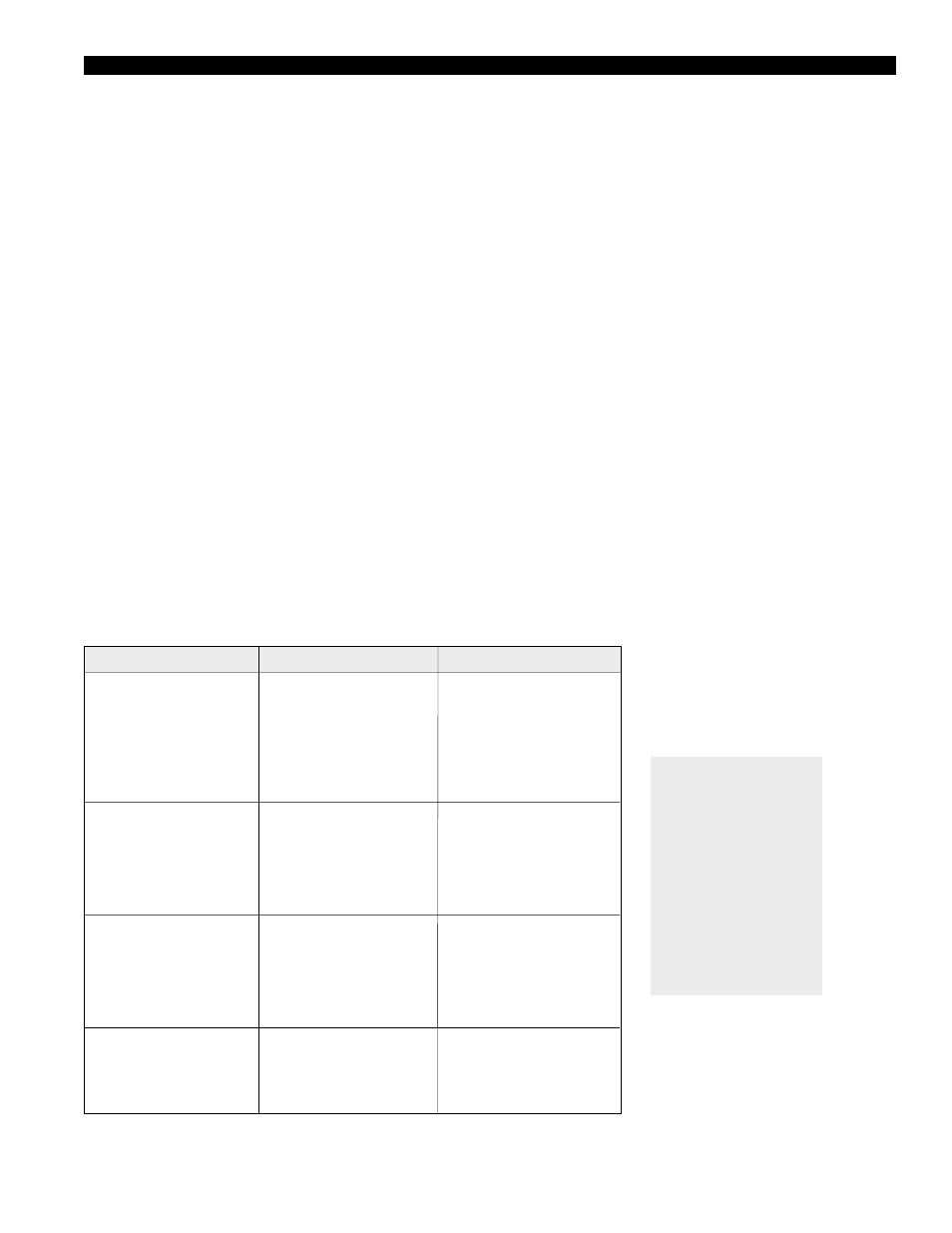

Symptom

Will not attain normal feed rate.

Will not feed when control arm

is moved.

Feed rate is sluggish under

load.

Hydraulic Feed will not pull in

logs over 4" in diameter, or

continuously stalls or stops.

Probable Cause

Engine not operating at cor-

rect speed.

Control linkage damaged or

binding.

Bypass valve stuck partially

open. (Problem in one direc-

tion only.)

Control linkage damaged or

not connected.

Drive between engine and

pump damaged.

Pump low on fluid.

Loose drive belt between

engine and pump.

Pump low on fluid.

Large amount of water in hy-

draulic fluid (evaporates

when hot, resulting in low fluid

level).

Hydraulic system overloading

and causing system to go

over relief.

Suggested Remedy

Repair engine governor.

Repair control linkage.

Repair bypass valve.

Remove foreign material from

valve.

3.3 Hydrostatic Pump Troubleshooting

Before servicing or

repairing any of the

hydrostatic feed

components (pump,

motor, and/or relief

valve), contact your

dealer or factory

service department.

Warranty on these

items may be void

without prior

authorization.

Caution: Hydraulic systems contain

fluid under high pressure. Never check

for leaks with your hands. Relieve

pressure before disconnecting any

hydraulic lines.

3.1.7 Greaseable Bearings and Pivots

The chipper has five greaseable bearings and pivots that

require grease every 50 hours:

• Two bearings on the rotor shaft.

• One greaseable bushing on the foot pedal pivot.

• One grease zerk on idler pivot.

• One grease zerk on discharge chute.

Service engine according to engine manual. Change

engine oil and filter as recommended in manual.

3.1.8 Trailer Service Tips

1. Check wheel bolt torque every 10 hours of towing use.

2. Check air pressure in tires every 10 hours of towing.

3. Check and repack wheel bearings with grease every

12 months.

4. When towing, always connect the safety chains.

Make sure trailer hitch bolts are tight and secure.

5. Check trailer lights.

3.2 Hydraulic Feed Maintenance

NOTE: Check the reservoir daily for proper fluid level,

the presence of water (noted by a cloudy to milky

appearance, or free water in bottom of reservoir), and

rancid fluid odor (excessive heat).

The hydrostatic pump normally does not require regular

fluid changes. The system filter should be changed at

250 hour or annual intervals. The fluid and filter should

be changed and system cleaned if the fluid becomes

contaminated with foreign matter (water, dirt, grease,

etc.) or if the fluid has been subjected to temperature

levels greater than the maximum recommended.

There is a greaseable bearing on each side of the shaft

on the hydraulic feed housing. Grease periodically.