Echo 7812086 Owners Manual v.3 User Manual

Page 22

12 INCH CHIPPER

18

SERVICE & MAINTENANCE

BEFORE INSpECTINg OR SERvICINg ANY pART OF ThIS MAChINE, ShuT OFF pOwER SOuRCE, REMOvE kEY,

DISCONNECT ThE BATTERY CABLES AND MAkE SuRE ALL MOvINg pARTS hAvE COME TO A COMpLETE STOp.

WarninG

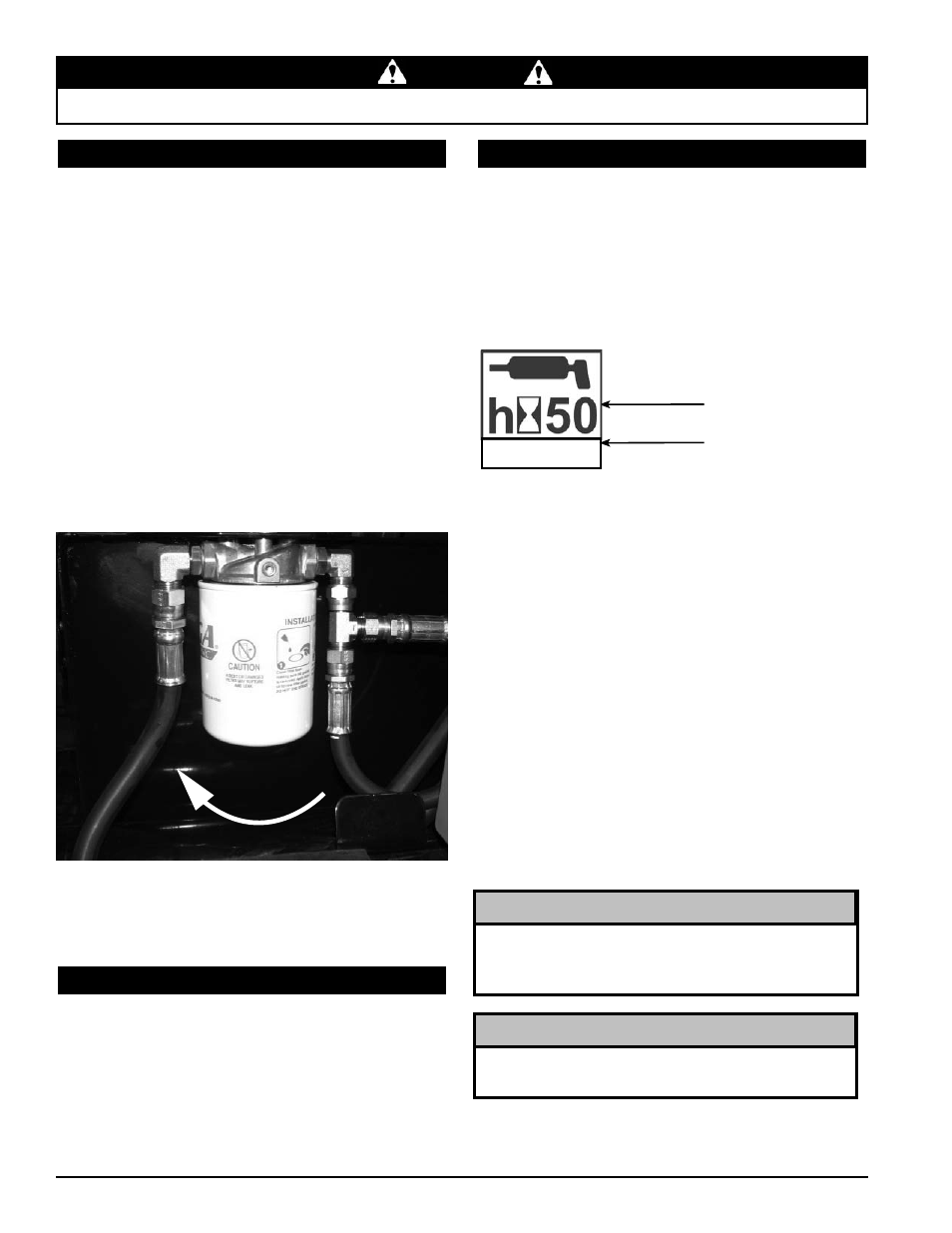

The hydraulic oil filter should be changed every 250 hours

of operation. To do this:

using an oil filter wrench turn the filter as indicated

below.

Once the filter becomes loose, turn it out the rest of

the way with your hand.

properly discard old filter.

Lube the rubber seal on the new filter with clean hy-

draulic oil.

Install the filter onto the threaded pipe. Turn by hand

until the filter is finger tight.

using an oil filter wrench, tighten the filter another

1/2 turn.

Check hydraulic oil level and fill if necessary.

1.

2.

3.

4.

5.

6.

7.

Check wheel bolt torque every 8 hours of towing

use.

Check air pressure in tires every 50 hours. Fill to the

recommended pSI located on the tire sidewall.

Check and repack wheel bearings with grease every

year.

1.

2.

3.

polyuria and lithium based greases are not compatible.

Mixing the two grease types may lead to premature

failure of the chipper.

The use of pneumatic grease equipment is not

recommended unless low pressure is assured.

Mounted bearings are lubricated at our factory and are

ready for operation.

relubriCation

Relubrication of bearings is determined by operating

conditions and environment. Lubricate standard bearings

with a lithium-based grease. greasing intervals and

quantities are shown on the next page using the following

symbol:

Q

uantity

Frequency (50 hours)

Recommended

quantity of grease

GreaSinG.intervalS

Bearings in extreme environments will require more

frequent greasing intervals.

GreaSe.fill.amountS

The quantities shown on the next page are recommended

amounts. Experience will show correct fill amounts due

to wide variances in applications, greasing equipment and

operating conditions. In most cases, it is best to lubricate

in small amounts, under low pressure, until a thin bead of

fresh grease is visible at the seal lip area.

Care should be taken when greasing bearings to avoid

overfilling. Overfilling can lead to excessive heat and/or

unseating of the seals grease should be introduced

in small amounts and under light pressure. whenever

possible, the bearing should be rotated slowly while

grease is added to ensure equal distribution throughout

the raceways.

5.9..ChanGe.hyDrauliC.oil.filter

5.10..trailer.ServiCe.tipS

note

note

5.11..GreaSinG.bearinGS

Loosen hydraulic oil filter and remove