6 lubrication, 7 clearing a plugged rotor, 6 lubrication 5.7 clearing a plugged rotor – Echo CH611DH Owners Manual v.2 User Manual

Page 22: Important

18

6 INCH CHIPPER

SERVICE & MAINTENANCE

BEFORE INSPECTINg OR SERVICINg ANy PART OF THIS MACHINE, SHuT OFF POWER SOuRCE,

DISENgAgE THE HyDRAulICS, AND MAKE SuRE All MOVINg PARTS HAVE COME TO A COMPlETE STOP.

WaRNING

5.6 LubRICaTIoN

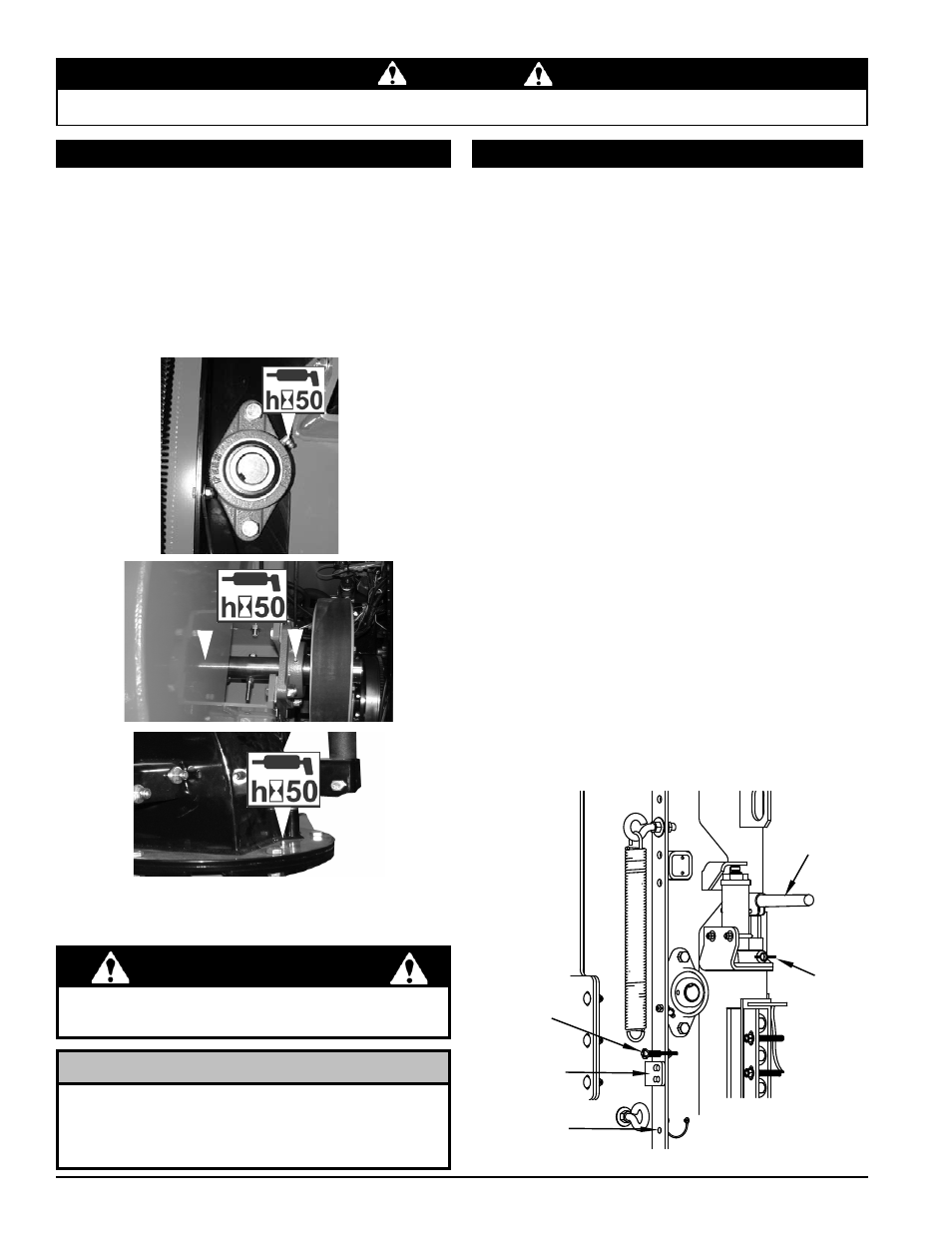

Grease zerk on bearing assembly (top). Two grease zerks are on

the drive shaft. The one on the left is located under the access cover

(middle). One zerk is on the discharge chute base (bottom).

5.7 CLEaRING a pLuGGED RoToR

FEED

ROLLER

JACK

LOCK PIN

STORAGE

POSITION

SUPPORT

BRACKET

LOCK PIN

POSITION

CHECK

VALVE

Feeding too large or too much material at once may plug

the chipper. To clear a plugged disk, proceed as follows:

lift the engagement handle and turn off engine key

1.

switch. Allow all moving parts to come to a complete

stop.

Remove the two 3/8” retaining bolts holding the access

2.

cover to the chipper frame and lift up access cover.

Remove the lock pin from storage position (see

3.

below).

Turn check valve clockwise to engage the jack pump.

4.

Pump the handle to raise the feed roller until the lock pin

5.

position aligns with one of the support bracket holes.

Secure the position by putting the lock pin through the

6.

support bracket and lock pin position.

Clean the debris away from the chipper disk. Turn the

7.

disk by hand to be sure it is free to rotate. Be careful

to avoid the chipper blades when cleaning out the

debris.

Remove the lock pin and put it back in storage

8.

position. lEAVINg THE lOCK PIN IN ANy OTHER

POSITION MAy INTERFERE WITH FEED ROllER

OPERATION.

turn the check valve counterclockwise to disengage

9.

the pump and lower the jack.

Close access cover and replace bolts.

10.

Start the engine. Lower the engagement handle

11.

when engine is running to engage drive belt. Resume

operation at 1/4 throttle.

Do not over grease bearings. Overfilling can lead to

excessive heat and/or unseating of the seals. Add

grease slowly and under light pressure. Whenever

possible, rotate bearing slowly while lubricating.

NoTE

Polyurea and lithium-based greases are not compatible.

Mixing the two grease types may lead to premature failure.

ImpoRTaNT

lubricate the machine periodically with a lithium-based

grease. Extreme working conditions will require more

frequent greasing.

grease the following points every 50 hours of operating

time: Two are located on the bearing assembly (one on

each side of the chipper). Two are accessed by opening

the hood of the chipper. One zerk is on the discharge chute

base (see pictures below).