9 replacing drive belt, 10 change oil, 11 lubrication – Echo CH911DH Owners Manual v.3 User Manual

Page 20: Important

9 INCH CHIPPER

16

SERVICE & MAINTENANCE

BEFORE INSPECTINg OR SERVICINg ANy PART OF THIS MACHINE, SHuT OFF POWER SOuRCE,

AND MAkE SuRE All MOVINg PARTS HAVE COME TO A COMPlETE STOP.

WaRNING

5.11 LubRICaTIoN

• Two bearings on the rotor shaft.

• Two bearings on the hydraulic feed roller.

• One bushing on the belt engagement pedal pivot.

• One grease zerk on idler pivot.

• One grease zerk on discharge chute.

See following page for grease zerk locations.

lubricate the machine periodically with a lithium-based

grease. Extreme working conditions will require more

frequent greasing.

grease the following points every 50-100 hours of

operating time:

ImpoRTaNT

Polyurea and lithium-based greases are not

compatible. Mixing the two grease types may lead to

premature failure.

NoTE

Do not over grease bearings. Overfilling can lead to

excessive heat and/or unseating of the seals. Add

grease slowly and under light pressure. Whenever

possible, rotate bearing slowly while lubricating.

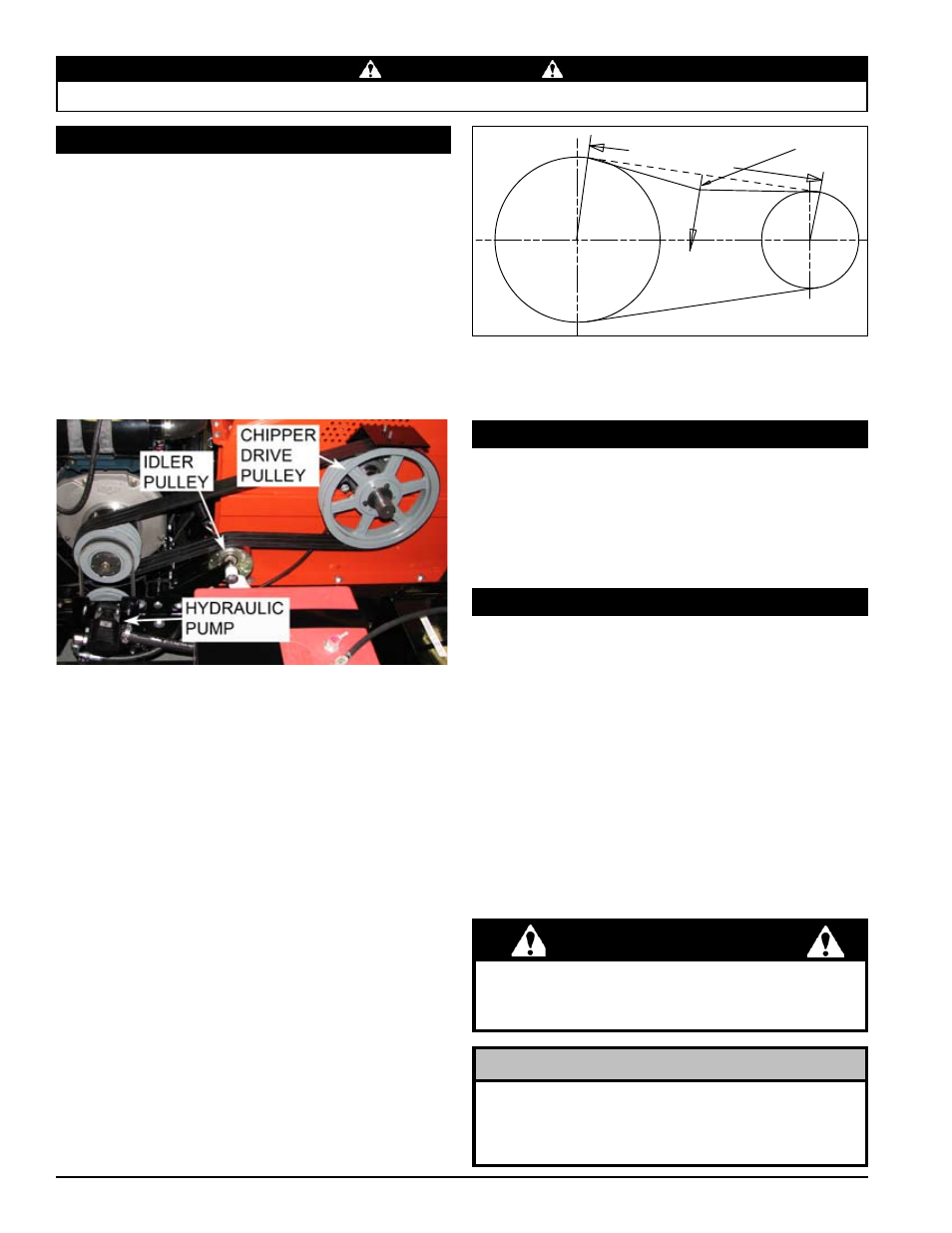

5.9 REpLaCING DRIvE bELT

Shut off engine.

1.

Remove drive belt shield.

2.

Remove the hydraulic pump belt by loosening the bolts

3.

on the hydraulic pump (Figure 5.4).

SPAN LENGTH

FORCE

20 LBS

7/16" DEFLECTION

Figure 5.5, Belt tension

Take the tension off the drive belt by depressing the belt

4.

engagement pedal. Remove the drive belt from pulleys.

Install the new drive belt on pulleys.

5.

Check pulley alignment with a straight edge and adjust

6.

engine if needed.

Check belt tension and adjust if needed. The belt

7.

deflection at the center of the belt should be 7/16"

when a 20 lb. load is placed against the belt (see Figure

5.5).

Reinstall hydraulic pump belt. Readjust hydraulic

8.

pump belt tension by sliding the hydraulic pump in the

mounting slots. Tighten bolts.

Replace belt guard.

9.

Depress belt engagement pedal, start engine, engage

10.

drive belt, and test unit. Readjust pulleys and belt

tension if needed.

Figure 5.4, Drive belt

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. If the belt is

cracked, worn, frayed, or stretched, replace it. Replace

belt with original banded belt type only. Do not use single

type belts.

To replace the belt:

5.10 CHaNGE oIL

Check the oil level before each use. Change oil as directed

in the engine owner's manual.

The controller will blink a code every 100 hours as a

reminder to change oil. To reset the controller, see Sec.

7.3.