JLG 45e Service Manual User Manual

Page 38

SECTION -

-12

– JLG Lift –

3120861

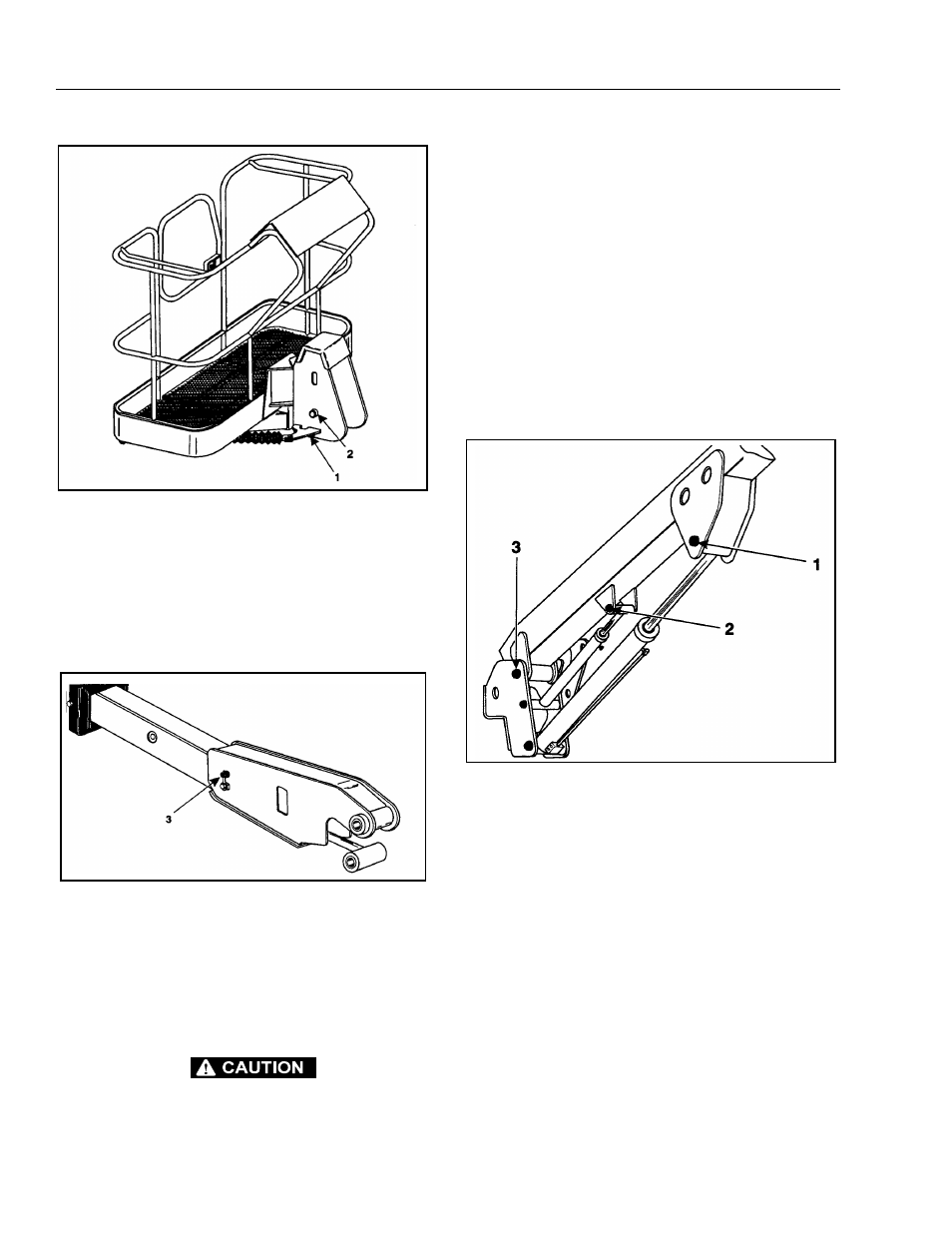

e. Supporting the slave cylinder, remove the hard-

ware from pin #3. Using a suitable brass drift

and hammer, remove pin #3 from the fly boom.

f.

Tag and disconnect hydraulic lines to the slave

leveling cylinder. Use a suitable container to

retain any residual hydraulic fluid. Cap hydraulic

lines and ports. Remove the slave cylinder.

2.

Remove the boom from upright as follows:

a. Remove hardware securing the cover plate on

the side of the base boom section and remove

hose clamps. Disconnect wiring harness from

ground control harness connector.

HYDRAULIC LINES AND PORTS SHOULD BE CAPPED IMMEDI-

ATELY AFTER DISCONNECTING LINES TO AVOID ENTRY OF

CONTAMINANTS INTO SYSTEM.

b. Tag and disconnect hydraulic lines from boom

to control valve. Use a suitable container to

retain any residual hydraulic fluid. Cap hydraulic

lines and ports.

c. Using a suitable lifting equipment, adequately

support boom weight along entire length.

d. Remove hardware securing the lift cylinder pin

#1. Using a suitable brass drift and hammer,

remove pin #1 from the base boom.

e. Remove hardware securing the master cylinder

pin #2. Using a suitable brass drift and hammer,

remove pin #2 from the base boom.

f.

Remove hardware securing the base boom pin

#3. Using a suitable brass drift and hammer,

remove pin #3 from the upright.

g. Using all applicable safety precautions, carefully

lift boom assembly clear of upright and lower to

ground or suitable supported work surface.

Figure 2-5. Location of Components -

Platform Support. (Models 35/n35/40/n40/45)

Figure 2-6. Location of Components - Slave Leveling

Cylinder.

Figure 2-7. Location of Components - Removal of Base

Boom. (Models 35/n35/40/n40/45)