4 torque specifications, 5 lubrication, Cylinder specifications -4 – JLG 45e Service Manual User Manual

Page 11

SECTION 1 - SPECIFICATIONS

3120861

– JLG Lift –

1-3

Machine Width.

30 electric - 1.75 m.

35 electric - 1.75 m.

n35 electric - 1.50 m.

40 electric - 1.75 m.

n40 electric - 1.50 m.

45 electric - 1.75 m.

Wheel Base.

30 electric - 1.93 m.

35/n35 electric - 2.01 m.

40/n40 electric - 2.01 m.

45 electric - 2.01 m.

Working Height.

30 electric - 9.14 m.

35/n35 electric - 10.67 m.

40/n40 electric - 12.19 m.

45 electric - 13.72 m.

1.4

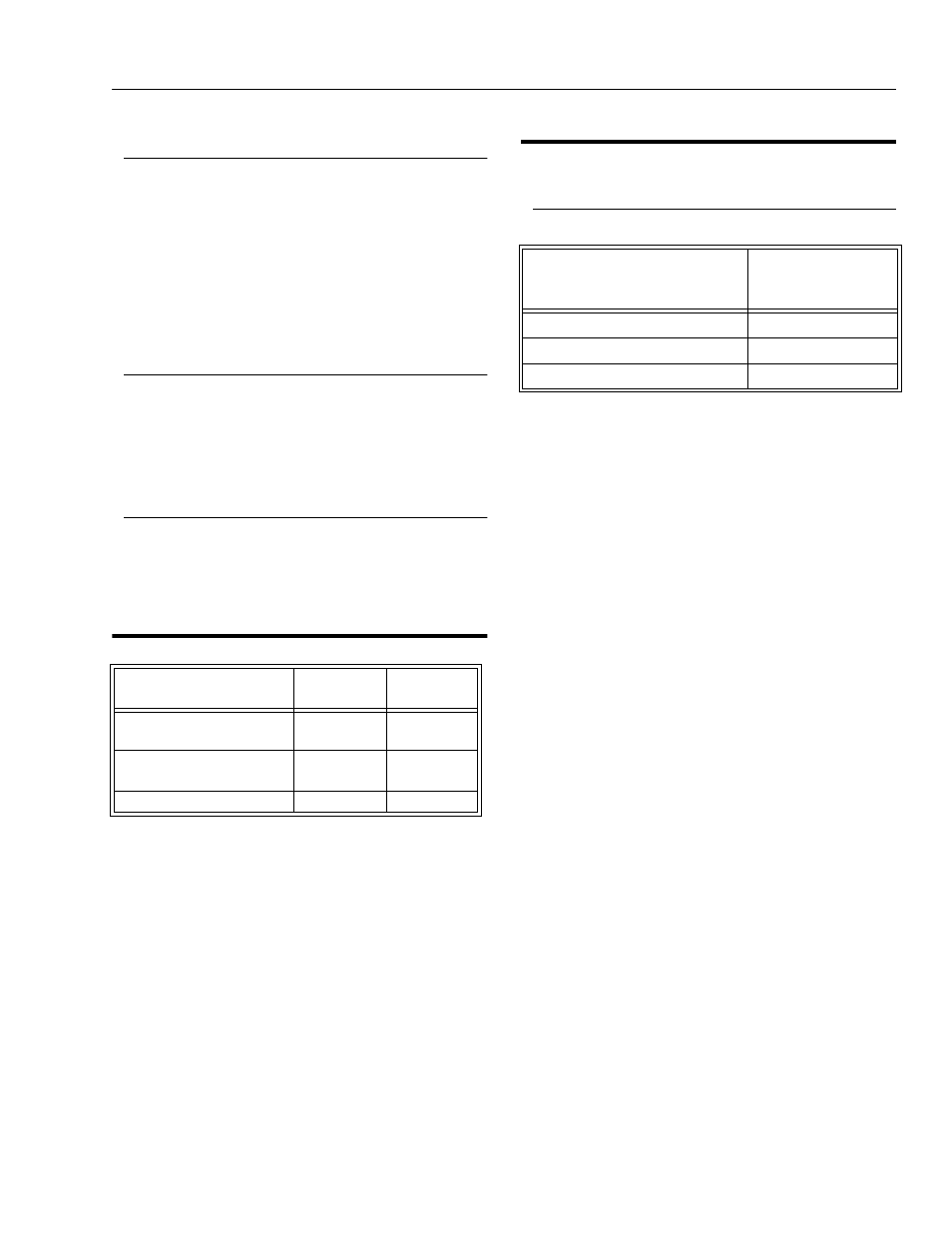

TORQUE SPECIFICATIONS.

NOTE: *Check swing bearing bolts for security after first 50

hours of operation and every 600 hours thereafter.

(See paragraph 2-16, - Swing Bearing.)

NOTE: When maintenance becomes necessary or a fas-

tener has loosened, refer to the Torque Chart, Figure

1-1, to determine proper torque value.

1.5

LUBRICATION.

Hydraulic Oil.

Table 1-1.

Hydraulic Oil.

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system ser-

vice. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity index of

152.

NOTE: When temperatures remain consistently below 20

degrees (-7 degrees C), an amount of no. 2 diesel

fuel, not to exceed 20% of system capacity, may be

added to the hydraulic oil reservoir. This diesel fuel

will “thin” the hydraulic oil for easier cold weather

operation, and will almost completely dissipate from

the hydraulic system over a several month period of

time. When cold weather is past, it may be neces-

sary to drain and refill the hydraulic system to rid the

system of any remaining diesel fuel.

NOTE: Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities. If use of hydraulic oil other

than Mobilfluid 424 is desired, contact JLG Indus-

tries for proper recommendations.

Description

Torque Value

(Dry)

Interval Hours

A. Bearing To

Chassis

See Note

50/600*

B. Bearing To

Turntable

See Note

50/600*

C. Wheel Bolts

122 Nm

150

HYDRAULIC SYSTEM

OPERATING

TEMPERATURE RANGE

SAE VISCOSITY GRADE

0 F to 23 F (-18 C to -5 C)

10W

0 F to 210 F (-18 C to +99 C)

10W-20,10W-30

50 F to 210 F (+10 C to +99 C)

20W-20