10 load sensing system, Calibration, 11 boom synchronizing procedure – JLG M450 ANSI Service Manual User Manual

Page 124: 12 footswitch adjustment, Load sensing system -12, Calibration -12, Boom synchronizing procedure -12, Footswitch adjustment -12, 10 load sensing system calibration

SECTION 4 - BOOM & PLATFORM

4-12

– JLG Lift –

3121127

3. Align bottom tubes with attach holes in rotator sup-

port. Using a soft head mallet, install rotator support

pin #5 into articulating jib boom and secure with

mounting hardware.

4. Align articulating jib boom with attach hole in articu-

lating jib boom pivot weldment. Using a soft head

mallet, install rotator support pin #4 into articulating

jib boom and secure with mounting hardware.

5. Align bottom tubes with attach holes in articulating

jib boom pivot weldment. Using a soft head mallet,

install rotator support pin #3 into articulating jib

boom pivot weldment and secure with mounting

hardware.

6. Align articulating jib boom pivot weldment with

attach holes in fly boom assembly. Using a soft head

mallet, install pivot pin #2 into fly boom assembly

and secure with mounting hardware.

7. Align the slave leveling cylinder with attach holes in

articulating jib boom pivot weldment. Using a soft

head mallet, install slave leveling cylinder pin #1

into articulating jib boom pivot weldment and secure

with mounting hardware.

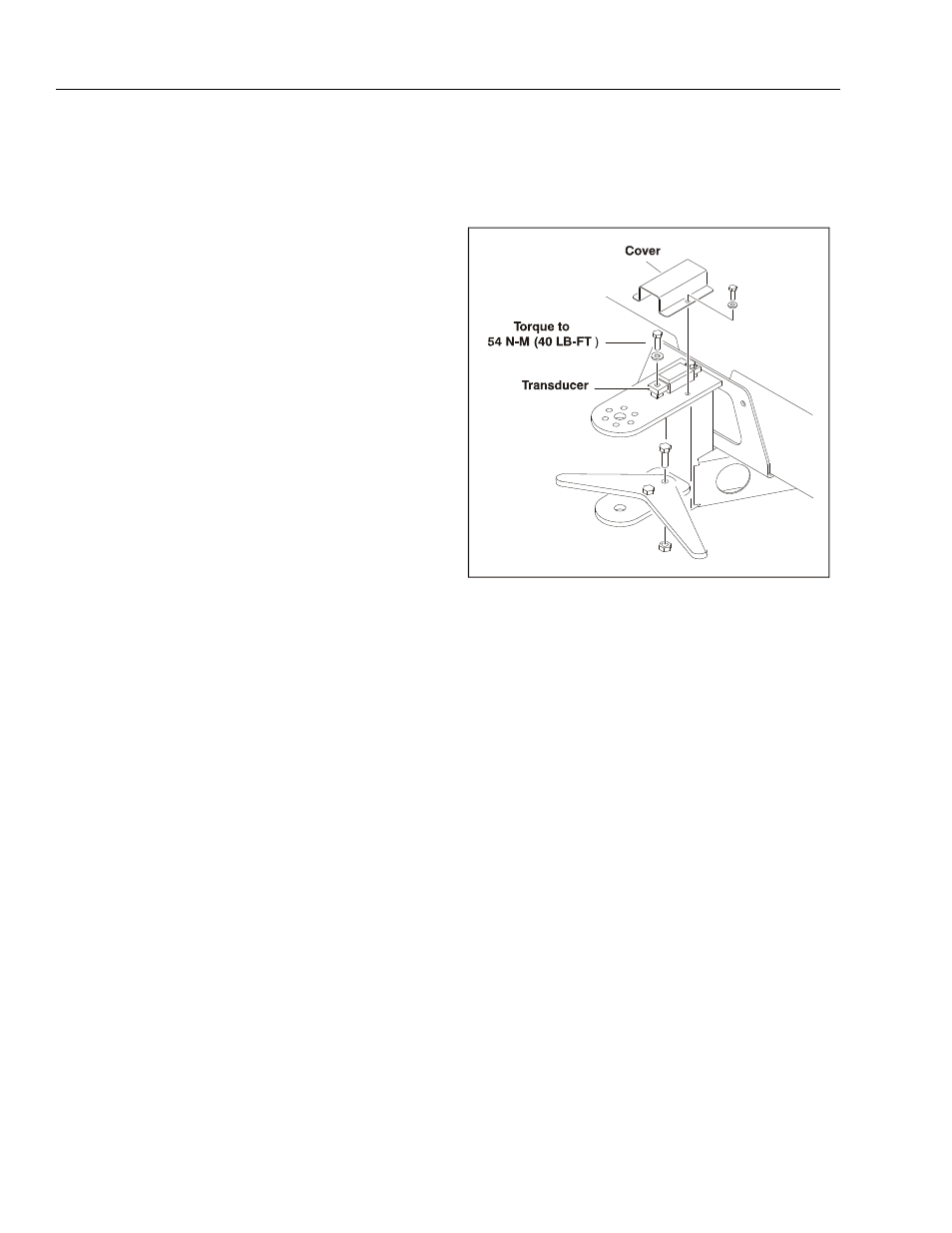

4.10 LOAD SENSING SYSTEM

Calibration

1. Place the machine in a stowed position.

2. Activate both Emergency Stop switches and turn the

Key switch to the platform position.

3. Remove all loads from the basket including opera-

tor.

4. Turn P1 clockwise (in) until the potentiometer begins

to click.

5. Plug the analyzer into port in the platform.

6. Enter password 33271.

7. Select Machine Set-up / Load Cell / 1= Warn Only.

8. Select Diagnostics / System / Load Cell on analyzer.

9. Adjust P2 until the load = 0%.

10. Place 455 LBS. in the center of the basket.

11. Adjust P1 until the load = 100%.

12. Verify that the overload lamp lights continuously and

the alarm sounds continuously during an overload

condition.

13. Remove weight from the basket.

14. Adjust P2 until the load = 0%.

15. Place 455 LBS. in the center of the basket.

16. Adjust P1 until the load = 100%.

17. Remove weight from the basket.

18. Seal potentiometer with fingernail polish.

4.11 BOOM SYNCHRONIZING PROCEDURE

NOTE: If the Lower Boom assembly does not fully lower:

1. Remove all personnel from the platform.

2. Pull the red knob located under the main control

valve.

3. From Ground Control, activate the lift control switch,

raise Lower Boom 6 feet (1.8m).

4. After raising Lower Boom, release the red knob.

5. Activate Lower Boom Down, fully lower boom.

6. Repeat step 1 thru 5 if necessary.

4.12 FOOTSWITCH ADJUSTMENT

Adjust switch so that functions will operate when pedal is

at center of travel. If switch operates within last 1/4 inch

(6.35 mm) of travel, top or bottom, it should be adjusted.

Figure 4-11. Load Sensing System