Snorkel A38E-sn004509+ User Manual

Page 50

Chapter 12 – Troubleshooting

46

A38E – 8210052

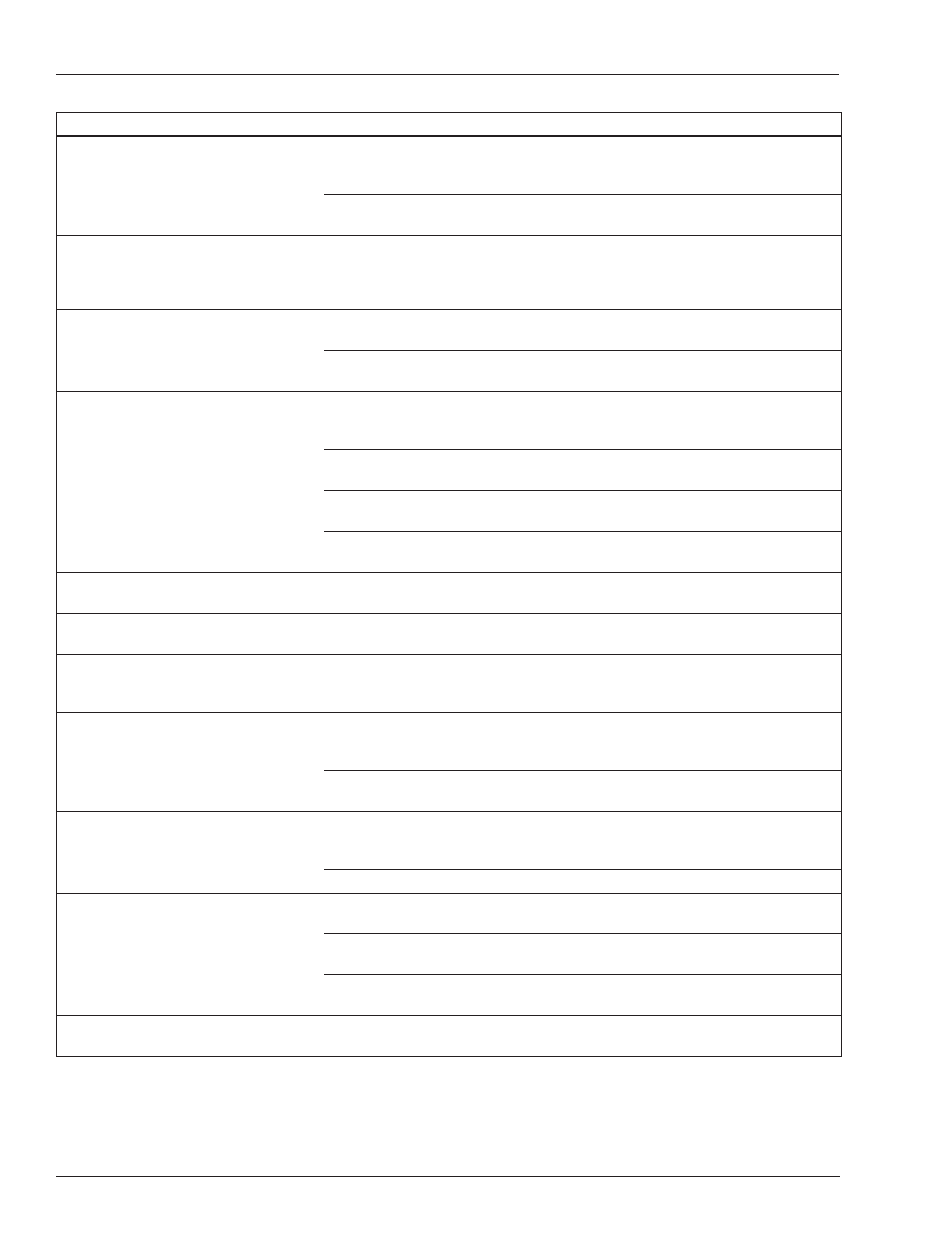

Symptom

Possible Cause

Corrective Action

Battery charge indicator does not

indicate a reading when charging

batteries.

No source of power.

Make sure power source is plugged

in and turned on.

Circuit breaker is tripped.

Unplug the charger until the internal

circuit breaker has reset.

Boom and drive functions seem

sluggish.

Hydraulic oil is cold and thick.

Use cold weather hydraulic oil as

recommended for weather condi-

tions. Warm oil before operating the

machine.

Riser and/or main boom drifts

down.

Hydraulic system malfunction.

Stow the machine and do not oper-

ate until repairs are made.

Emergency lowering knob pushed

in.

Pull knob outward to normal operat-

ing position.

Drive functions will not work.

Load capacity exceeded.

Remove load from platform. Refer to

platform capacity placard for maxi-

mum capacity.

Machine is not on a level surface or

too steep of a grade.

Lower the platform and drive to a

level surface.

Drive hubs are disengaged.

Turn drive wheel disconnect socket

screws fully counterclockwise.

Low hydraulic system pressure.

Stow the machine and do not oper-

ate until repairs are made.

Can not reach maximum drive speed

of 2.5 mph (4 km/h).

Booms are not retracted and low-

ered.

Fully retract and lower the boom.

Wheels will not turn when winching.

Drive hubs are engaged.

Turn drive wheel disconnect plates

around so nipples point inward.

Tilt alarm does not work.

Booms are stowed.

Normal operation. The tilt alarm is

operational when the booms are

near horizontal.

Circuit breaker will not reset.

Electrical circuit has not had time

to cool.

Wait a minute or two for circuit to

cool, then push circuit breaker button

in to reset.

Electrical system malfunction.

Stow the machine and do not operate

until repairs are made.

Electrical outlet does not work.

Power supply not plugged in.

Plug a source of power into the

power-input connector on the wiring

box.

GFCI is tripped.

Push reset button on outlet.

Hydraulic fluid temperature of 200°F

(93°C) or more.

Prolonged boom operation.

Stop operation until fluid cools.

High pressure fluid return to reservoir

caused by kinked or twisted hose.

Remove the kink or twist from the

hose. Let fluid cool before operating.

Hydraulic system component failure.

Stow the machine and do not operate

until repairs are made.

Severe hydraulic leak.

Failure of hose, tube, fitting, seal, etc.

Do not operate machine until repairs

are made.