Daily checks – operator checklist – Snorkel Pop-Up Push 8 Eco User Manual

Page 26

Page 25 of 25

POP-UP PUSH 8 ECO

Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Section 7

MAINTENANCE AND

REPAIR RECORD

Daily checks – operator checklist

The following checklist has been provided to enable daily checks to be

undertaken prior to use of this

POP-UP PUSH 8 ECO

. These checks should

be carried out each working day or at the beginning of each shift. The

purpose of the checks is to identify any wear and tear or malfunction of the

machine’s components and systems.

WARNING

FAILURE TO UNDERTAKE THESE CHECKS MAY RESULT IN DEFECTS ON, OR

DETERIORATION OF THIS

POP-UP PUSH 8 ECO

GOING UNDETECTED AND

POSSIBLY RESULTING IN AN UNSAFE MACHINE

Note that Regulation 8 of the Lifting Operations and Lifting Equipment

Regulations 1998 (LOLER) require that persons using lifting equipment have

appropriate training and instructions to enable them to identify whether

lifting equipment is safe to use.

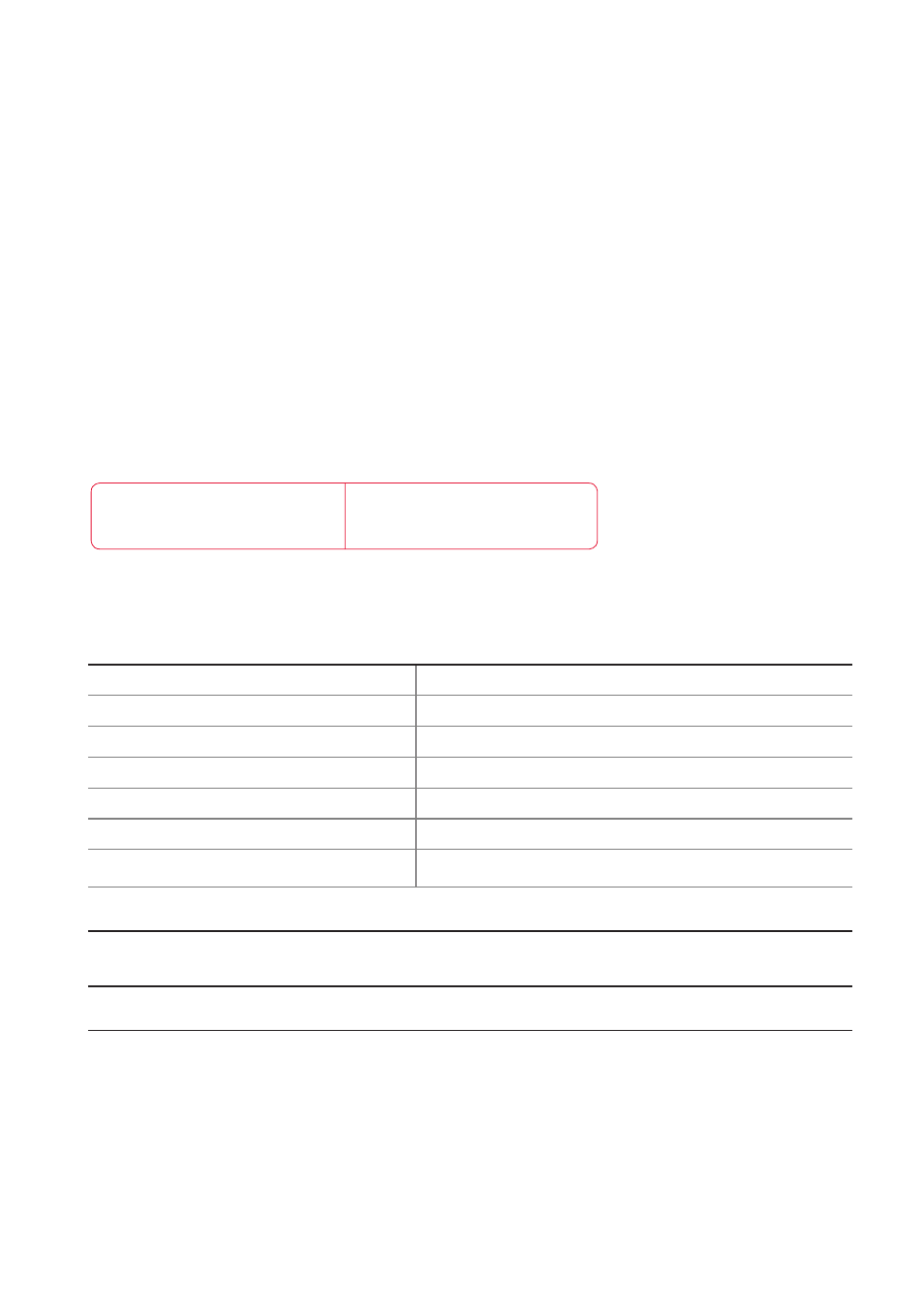

Machine number

1. Prior to operating the platform, the following items must be checked:

OK?

(please tick)

OK?

(please tick)

Structure

Battery condition

Platform

Raise and lower

Castors

Emergency stop

Rear manual brakes

Emergency lower

Front auto brakes

Limit switch

Hydraulic oil

Safety decals

Oil leaks

Stabilisers

(optional if

POP-UP PUSH 8 ECO is fitted with auto

brakes)

Date

Checked by

2. Use raise, lower and emergency stop functions to ensure correct operation.

Should any defects be identified in any of the above areas, these should be re-

ported to your employer. It may be necessary to further seek assistance from the

supplier of the machine, this may be the hire company or the manufacturer. You

should only rectify any defects if you are authorised and competent to do so.

Do not use the machine unless each of the items above is checked and

stated OK.