JUN-AIR JAir Dental Compressed Air System User Manual

Page 19

19

© 2011, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

JUN-AIR Dental Compressed Air System User Guide

CI-101A (Rev B)

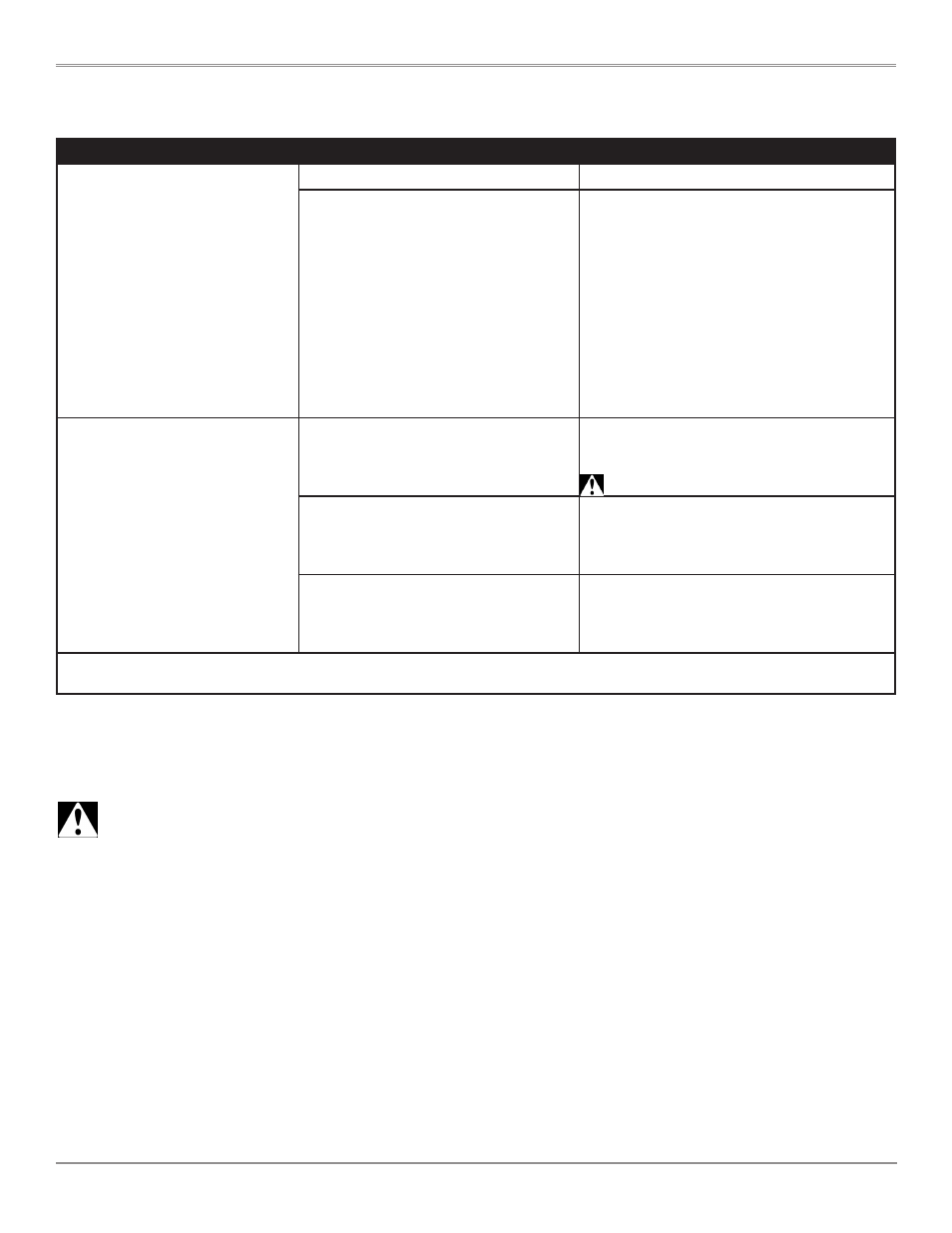

Problem

Possible Cause(s)

Possible Solution(s)

5 . Compressor cycles when there is

no air demand from the operator/

operatories

a. Leak in the compressor system

a . See 4C

b. Leak in the office air system

b. Look at the moisture indicator (see KEY PARTS

to locate .) If it is blue . . . .With the power switch

ON, (if necessary) drain the storage tank to 80

psi to start the compression cycle . When the

cycle shuts off at 100 psi, close the air outlet

valve . Wait 5 minutes . Open the air outlet valve .

If the pressure drops, (by more than 5 psi) the

air leak is in the office air system or delivery units

and not in the Compressor System . Call your

authorized dealer for service .

NOTE: If it is pink - see #6 below .

6. Moisture indicator is pink*

a. Leak in the office air system

a . If the moisture indicator is pink, there is too much

moisture in the system .

CAUTION: Call your authorized dealer for

service .

b . Compressor keeps cycling

b . Check the “SPECIFICATIONS” . There may be

excessive demands placed on the Compres-

sor System . A larger capacity model may be

required .

c . The solenoid valve requires attention

c . It is normal to hear air escaping from the sole-

noid valve when the compressor shuts off . If air

does not escape, the valve could be clogged or

sticking . Call your authorized dealer for service .

* In initial installations, the moisture indicator may appear pink before operating the system, this is due to ambient air in the sys-

tem and will change to blue after operation of the system .

TROUBLESHOOTING CHART

DIAGNOSTIC PROCEDURE FOR DEFECTIVE COMPRESSOR(S)

1 . Turn compressor power switches to the OFF

position .

WARNING: Always turn off compressor

and remove power from unit when ser-

vicing or removing electrical cover. Lock

out power at the breaker prior to servic-

ing.

2 . Reset the circuit breaker if it was previously

tripped .

3 . Test compressors by turning ONE on at a

time using compressor switches located in

electrical panel . (Start only 1 compressor at a

time and disconnect power between testing

compressors) . If the motor fails to start, or the

circuit breaker trips, the problem may be in that

compressor. Leave the compressor switch for

the defective compressor in the OFF position .

Call your authorized dealer for service .

NOTE: One or two compressors (depending

on system size) may be run temporarily while

waiting for service.

4 . If all compressors run independently, but will not

run together, check the line voltage . If the voltage

is within the min/max. voltage required in SITE

REQUIREMENTS, call your authorized dealer for

service .