Troubleshooting chart – JUN-AIR JAir Dental Compressed Air System User Manual

Page 18

18

CI-101A (Rev B)

JUN-AIR Dental Compressed Air System User Guide

© 2011, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

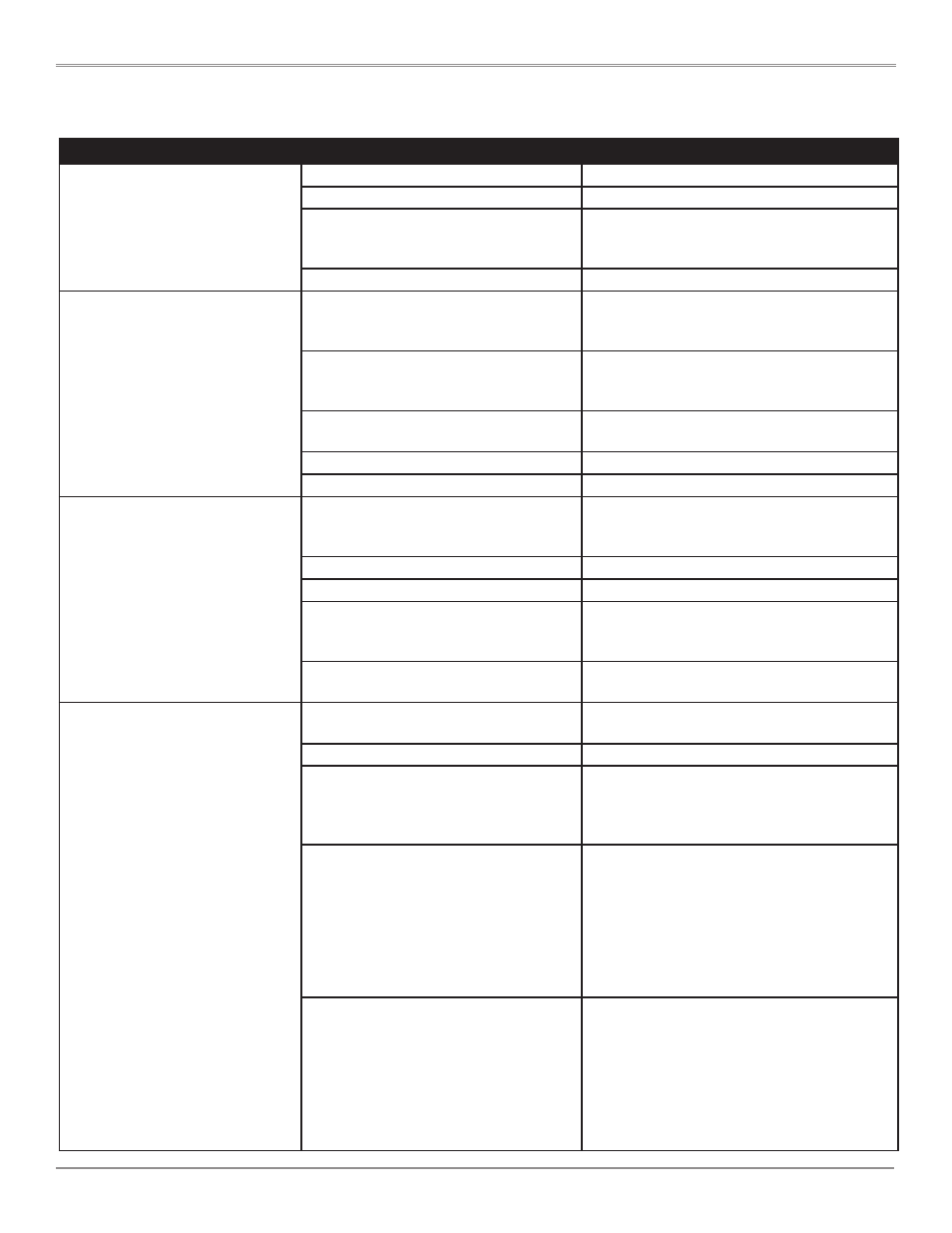

TROUBLESHOOTING CHART

Problem

Possible Cause(s)

Possible Solution(s)

1. Motor/compressor does not start

a . No electric power

a . Check circuit breaker at main power source

b . Power not connected

b . Check 24 volt remote connections

c . Defective power switch

c . Power switch needs to be replaced . Call your

authorized dealer for service . Check compres-

sor power switches are in the ON position

d. Fuse is blown/damaged

d . Check fuse in electrical enclosure

2 . Motor tries to start, circuit

breaker trips

a . Voltage too low . If each compressor head

runs separately, but not together, the volt-

age is too low

a . Compressor requires a minimum of 208 volts .

If the voltage is too below required minimum, a

buck-boost transformer must be installed

b . Solenoid valve does not open when com-

pression cycle ends

b . Check the solenoid valve . If it does not open at

the end of the cycle, call authorized dealer for

service

c . Pinched drain tubing from solenoid valve

c. Remove kink/pinch in drain line and verify proper

operation

d . Power supply cable too small

d . See SITE REQUIREMENTS

e. Loose electrical connection

e . Call authorize dealer for service

3 . Unusual or excessive noise

a . Intake filter(s) not seated correctly

a . Remove filter(s) and replace if clogged or dirty .

When installing, make sure filter chamber is

clean and filter is sealed properly .

b . Intake filter(s) clogged or dirty

b . Replace filters

c . Motor or compressor noise

c . Call authorized dealer for service

d . Air leaks

d . Close the air outlet valve . Check all fittings for

leaks . If leak is found, call authorized dealer for

service .

e . Check cooling fans

e . If fan is loose or broken, call authorized dealer for

service .

4 . Compressor cycles but does

not buid up pressure to 100 psi

a . Solenoid valve does not close or leaks

when compressor runs

a . Check the solenoid valve . Call authorized dealer

for service .

b . Clogged or dirty intake filters

b . Replace intake filters

c. Leak in compressor system

c . Close the air outlet valve . Check all fittings for

leaks . If leak is found, call authorized dealer for

service. (See “Testing Compressor for Leaks” in

MAINTENANCE section .)

d . Pressure switch needs adjusting

d . Disconnect main power supply . Drain air tank

slowly until you hear a “click” . Air tank should

read approx . 80 PSI on the system pressure

gauge . Close the air outlet valve, turn on the

power switch and verify the pump-up time for

your model . Call authorized dealer for service

(see “System Checks and Tests” for pump up

and recovery times .)

e. Leak in the office air system

e . With the power switch ON, ensure the compres-

sors are running . Close the air outlet valve and

wait for the compressor system to shut off at

100 psi . Wait 5 minutes and open the air outlet

valve . If the pressure drops (by more than 5 psi

or the compressors start again) the leak is in

the office air lines or delivery units . Contact your

authorized dealer for service