Lukas LS Series Cutter User Manual

Page 14

14

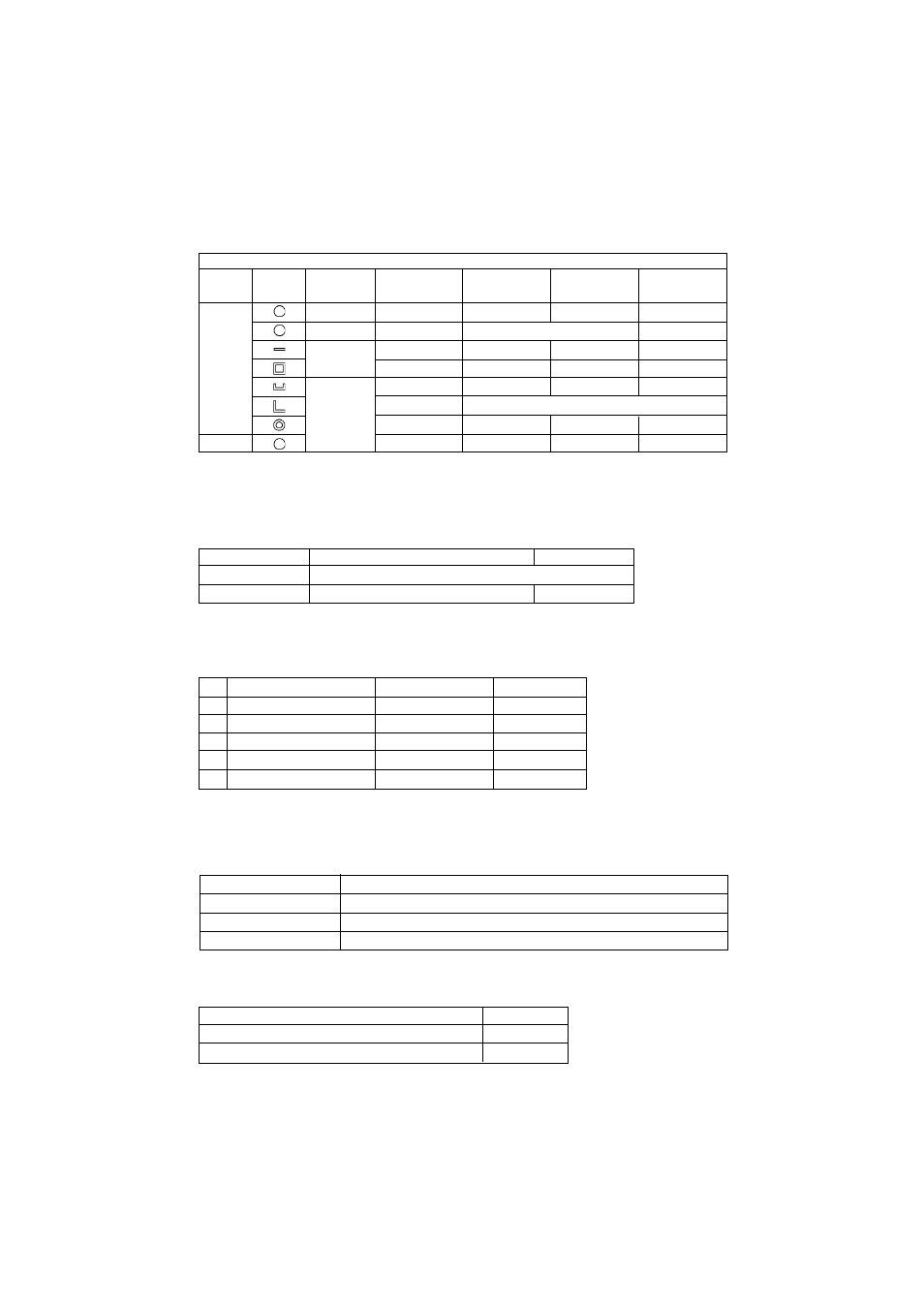

15.1 Cutting performance / cutting forces

The cutting performance is indicated for perfect condition of the blades (new or perfectly

reground), central bolts tightened in accordance with the specifications and correct handling (see

Section 9) of the devices.

15.2 Central bolt / Torque

15.3 Oil recommendations

For LUKAS hydraulic devices, use mineral oil in accordance with DIN 51 524 and others

Recommended viscosity range: 10 ... 200 mm²/s,

delivered with HLP 22 to DIN 51 524

15.4 LUKAS Hoses

15.5 Others

Type

LS 200 EN; LS 301 EN; LS 330 EN

LS 131 EN

Central bolt

M 24 x 1,5 (SW 36)

Torque (Nm)

120 + 10

100 + 10

Range of oil temperature

Viscosity rating

Remarks

A

- 24 ... + 30 °C

HL 5

B

- 18 ... + 50 °C

HLP 10

C

- 8 ... + 75 °C

HLP 22

D

+ 5 ... + 80 °C

HLP 32

E

- 8 ... + 70 °C

HF - E 15

biodegradable

Bending radius

Rmin = 38 mm

Burst resistance

safety factor: burst pressure / max. operating pressure, min. 4 : 1

Temperature resistance - 40°C ... + 100°C

Operating medium

Mineral oil according to DIN 51524

Working temperature

-20 ... +55°C

Ambient temperature (power pack in operation)

-24 ... +45°C

Storage temperature (power pack not in operation) -30 ... +60°C

Dimension of material

Type of Form of

Strength

LS 131 EN

LS 200 EN

LS 301 EN

LS 330 EN

material material Rm (N/mm

2

)

mm

mm

mm

mm

600 (500)

(Ш 24)

Ш 30

Ш 28

750

Ш 20

Ш 25

450

60 x 5

80 x 10

80 x 8

110 x 10

Steel

40 x 40 x 4

40 x 40 x 4

55 x 55 x 4

60 x 60 x 4

40 x 30 x 4

60 x 30 x 6

65 x 40 x 5

65 x 40 x 6

400

35 x 3

80 x 40 x 6

Ø 42.6 x 2,6

Ø 114 x 4.5

Ø 72.3 x 3.2

Ø 84.3 x 3.2

Alu

Ш 26

Ш 30

Ш 32

Ш 30