14 troubleshooting, 15 technical data – Lukas LS Series Cutter User Manual

Page 13

13

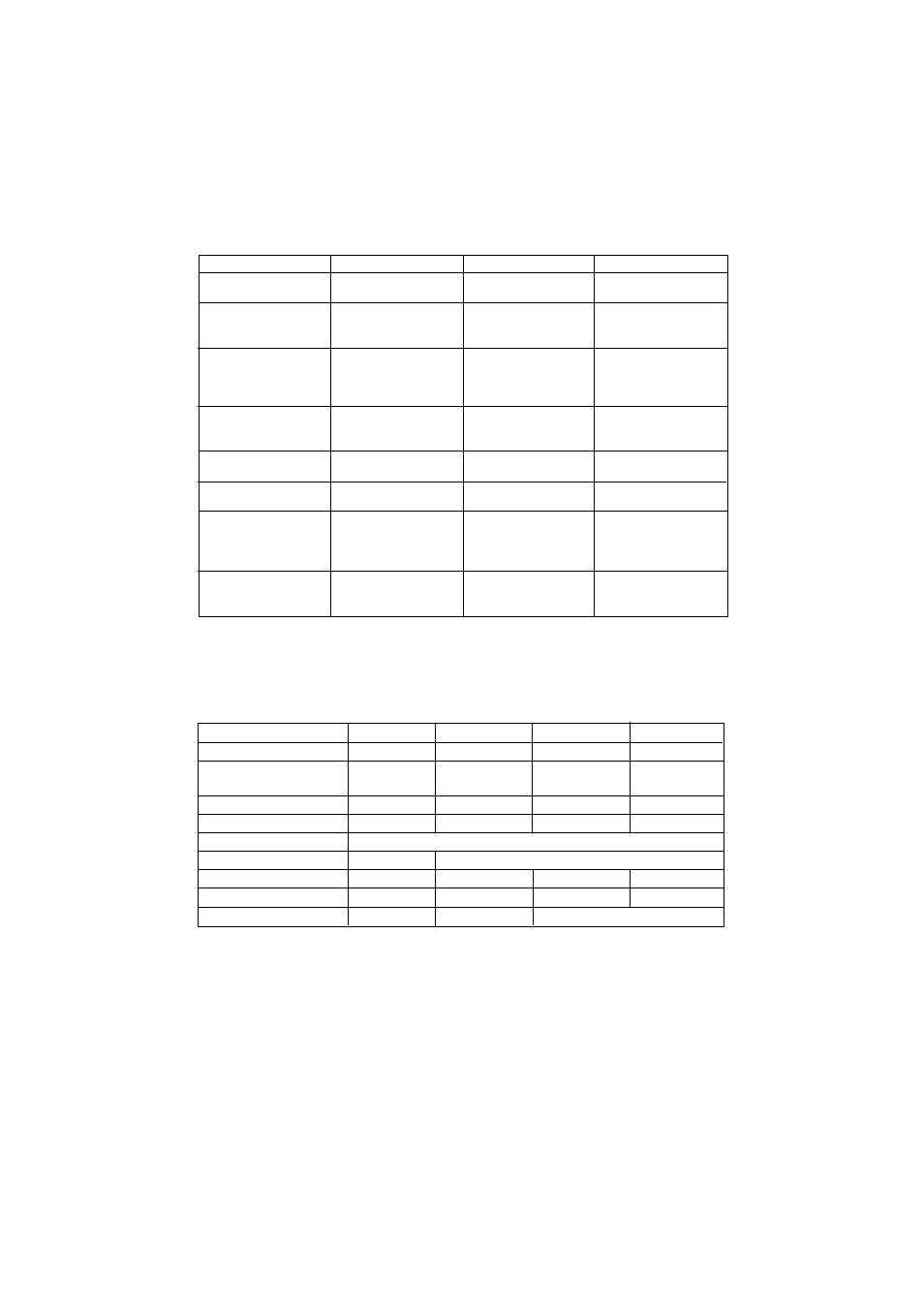

Trouble

Check

Cause

Remedy

Hoses cannot be

Pressurized

Relieve pump pressure

coupled

On actuating blades

Hoses correctly

Air in the hydraulic

Thoroughly vent pump

move slowly or by

connected power

system

unit: see 9.1.1

jerks

pack operating

No pressure build-up

Not enough oil in hand

Refill oil and vent the

resp. motor pump.

system (see operating

Vent pumpe after

instruction 9.1.1)

changing oil

Star grip doesn't return

Return spring is

Ask authorized dealer or

to middle position when

damaged or return

LUKAS themselves

released

mechanism is dirty

for repair

Oil leakage out of

Untightness, eventually Replace hoses

hoses or hose fittings

damages

Surface of hydraulic

Contact with

Change hoses

hoses is dissolved

agressive fluids

Blades spread up at

Torque of the center

For retightening, see

tips to a gap of more

bolt nut is unsuffisient

13.2.1

than 3 mm even if not

fully loaded

Leakages on the

Seal defective piston

Replacement of seals

piston rod

rod

by authorized dealer or

LUKAS themselves

14 Troubleshooting

If the defects cannot be repaired, contact an authorised LUKAS dealer or the LUKAS service

department. The address: LUKAS Hydraulik GmbH, Weinstraße 39, D-91058 Erlangen, Pf 2560,

D-91013 Erlangen, service phone 09131/698 348; fax 09131/698 353

15 Technical data

* 1MPa = 10 bar

1

Necessary oil quantity in the hydraulic power pack for operating the tool

(Difference in quantity piston / rode side)

Type

LS 131 EN

LS 200 EN

LS 301 EN

LS 330 EN

Ref. no.

84150/1334

84150/1260

84150/1301

84150/1388

Dimensions lxwxh without

connection hoses (mm)

563x170x142

663x190x163

705x190x163 726x190x163

Opening at the tips (mm)

140

125

150

225

Weight incl. oil filling (kg)

9.7

11.7

14.1

14.6

Operating pressure (MPa)

max. 63*

Necessary oil quantity (l)

1

0.025

0.2

prEN 13204

LHC 100 D

LHC 100 F

MHC 150 F

MHC 150 H

TÜV (DIN 14751)

S 01-2001-TP 18

S 51-99-TP 18

S 01-2002-TP 18

S 56-99-TP 18

French Standard NFS 61-571

CH 90 D

CH 90 E

CH 150 F