Bryant 764A User Manual

Page 6

Table 1 — Physical Data

UNIT 564A AND 764A

024

030

036

042

048

060

OPERATING WEIGHT (lb)

222

236

250

297

310

350

COMPRESSOR TYPE

Reciprocating

REFRIGERANT

R-22

Charge (lb)

2.8

3.9

4.7

4.4

6.1

7.5

REFRIGERANT METERING DEVICE

Acutrol™ System

CONDENSER COIL

Copper Tubes, Aluminum Plate Fins

Rows...Fins/in.

1...17

1...17

2...17

1...17

2...17

2...17

Total Face Area (sq ft)

6.7

7.9

6.2

11.1

8.6

10.7

CONDENSER-FAN MOTOR

Propeller

Cfm

1600

2000

2000

2600

2600

2800

Nominal Rpm

825

1100

1100

1100

1100

1100

Motor Hp

1

⁄

8

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

Diameter (in.)

20

20

20

20

20

20

EVAPORATOR COIL

Copper Tubes, Aluminum Plate Fins

Rows...Fins/in.

2...15

3...15

3...15

3...15

3...15

4...15

Total Face Area (sq ft)

2.8

2.8

3.1

3.9

4.3

4.9

EVAPORATOR-FAN MOTOR

Direct Drive

Blower Motor Size (in.)

10 x 8

10 x 8

10 x 8

10 x 9

10 x 9

10 x 10

Nominal Cfm

800

1000

1200

1400

1600

2000

Rpm Range

550-1000

550-1000

800-1050

800-1050

1000-1100

950-1100

Number of Speeds

3

3

3

3

2

3*

Factory Speed Setting

Low

Med

Low

Med

Low

Low

Motor Hp

1

⁄

4

1

⁄

4

1

⁄

2

1

⁄

2

3

⁄

4

1

CONNECTING DUCT SIZES

Round

Square

Supply Air (in.)

14

13.9 x 13.9

Return Air (in.)

14

13.9 x 27.8

FIELD-SUPPLIED RETURN AIR FILTER†

Throwaway (in.)

24 x 24

24 x 24

24 x 24

24 x 24

24 x 30

24 x 30

*460-v motors are 2-speed only.

†Required filter sizes shown are based on the ARI (Air Conditioning and Refrigeration Institute)

rated airflow at a velocity of 300 ft/min for throwaway type or 450 ft/min for high capacity type.

Recommended filters are 1-in. thick.

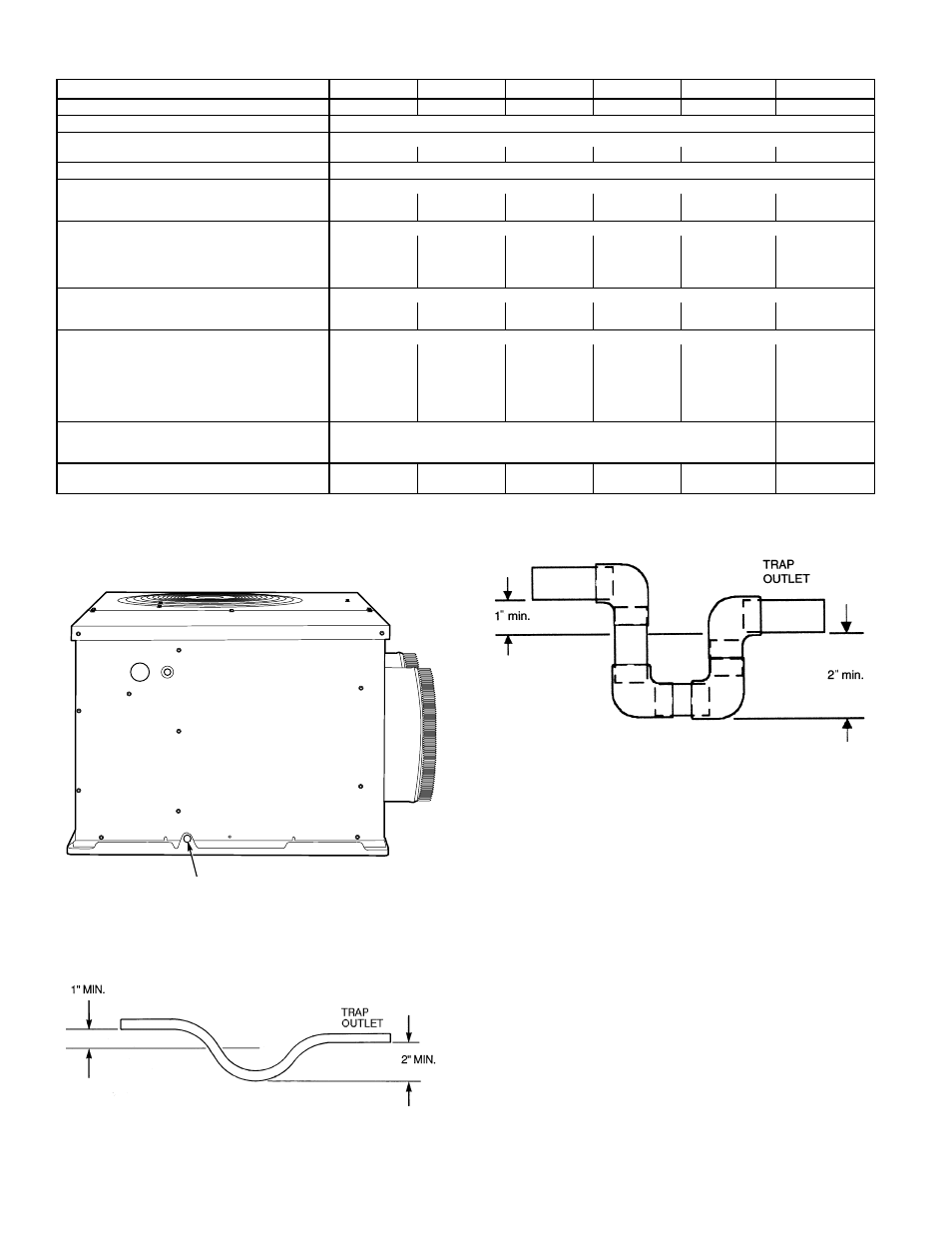

If the installation requires draining the condensate water

away from the unit, install a field-supplied 2-in. trap using

3

⁄

4

-in. OD tubing or piping to ensure proper drainage. See

Fig. 8A and 8B. Make sure that the outlet of the trap is at

least one in. lower than the unit drain pan condensate con-

nection to prevent the pan from overflowing. Connect a drain

tube using a minimum of

3

⁄

4

-in. PVC,

3

⁄

4

-in. CPVC, or

3

⁄

4

-in.

copper pipe (all field-supplied). Do not undersize the tube. Pitch

the drain tube downward at a slope of at least 1 inch in every

10 ft of horizontal run. Be sure to check the drain tube for

leaks. Prime trap at the beginning of cooling season start-up.

Allowable glues for condensate trap connection are: Stand-

ard ABS, CPVC, or PVC cement.

B. Field-Duct Connections

NOTE:

The design and installation of the duct system must

be in accordance with the standards of NFPA for the instal-

lation of nonresidence-type air conditioning and ventilating

systems, NFPA 90A or residence-type, NFPA 90B, and/or

local codes and ordinances.

Units have duct flanges on the supply- and return-air open-

ings on the side of the unit. See Fig. 2-4 for connection sizes

and locations.

CONDENSATE DRAIN HOLE

Fig. 7 — Condensate Connection Details

Fig. 8A — Condensate Trap (Using Tubing)

Fig. 8B — Condensate Trap (Using PVC Piping)

—6—