Bryant 764A User Manual

Page 13

C. Unit Controls

Compressor

High-Pressure Relief Valve — Valve is located in compressor.

Relief valve opens at a pressure differential of approximately

450 psi between suction (low side) and discharge (high side)

to allow pressure equalization.

Internal Current and Temperature Sensing Overload —

Device resets automatically when internal compressor motor

temperature drops to a safe level. When an internal overload

is suspected of being open, check by using an ohmmeter or

continuity tester.

D. Cooling Sequence of Operation

NOTE:

With the FAN switch in the ON position, 24 v is sup-

plied to the time-delay relay (TDR) through the G terminal

on the thermostat. This voltage energizes the coil of the re-

lay, closing the normally-open set of contacts which provide

continuous power to the indoor (evaporator) fan motor (IFM).

Moving the FAN switch back to the AUTO. position (provid-

ing there is not a call for cooling) deenergizes the TDR (when

applicable) which deenergizes the IFM after a 30-second de-

lay. The FAN switch in AUTO. position cycles upon a call for

cooling.

On a call for cooling, 24 v is supplied to the compressor con-

tactor (C) and TDR simultaneously through the Y and G ter-

minals of the thermostat, respectively. On units with a com-

pressor TDR, there is a built-in, 5-minute (±45 seconds) delay

between compressor starts. Energizing the contactor closes

the normally-open set of contacts supplying power to both the

compressor and outdoor (condenser) fan motor (OFM). Ener-

gizing the TDR closes the normally-open set of contacts pro-

viding power to the IFM. On the loss of the call for cooling,

24 v is removed from both the Y and G terminals of the ther-

mostat (providing the FAN switch is in the AUTO. position),

deenergizing both the compressor and TDR and opening both

the contacts supplying power to compressor and OFM. IFM

has a 30-second delay.

III. INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

CAUTION:

For cooling operation, the recommended

airflow is 350 to 450 cfm per each 12,000 Btuh of rated

cooling capacity.

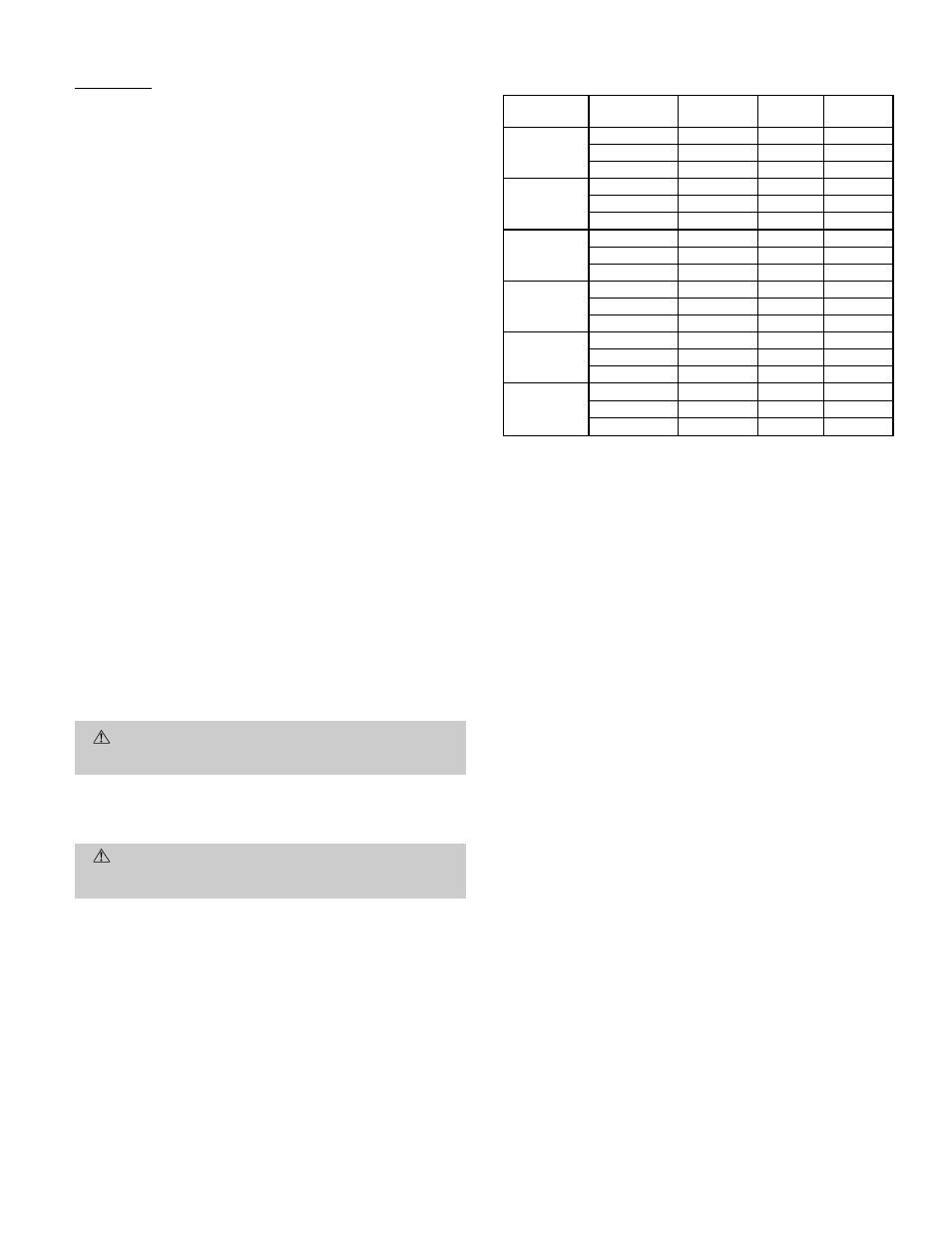

Table 3 shows dry coil air delivery for horizontal discharge

units.

WARNING:

Disconnect electrical power to the unit be-

fore changing blower speed. Electrical shock can cause

personal injury or death.

Airflow can be changed by changing the lead connections of

the blower motor.

Units 564A/764A024, 036, 048, and 060 blower motors are

factory wired for low speed operation. Units 564A/764A030

and 042 are factory wired for medium speed operation.

Table 3 — Dry Coil Air Delivery —

Horizontal Discharge

UNIT

564A/764A

IFM SPEED

SETTING

AIRFLOW

(Cfm)

ESP

(in. wg)

POWER

(Watts)

024

Low

800

0.30

282

Med

800

0.65

349

High

800

0.80

439

030

Low*

1000

—

—

Med

1000

0.35

370

High

1000

0.65

460

036

Low

1200

0.30

445

Med

1200

0.50

480

High

1200

0.65

530

042

Low*

1400

—

—

Med

1400

0.30

495

High

1400

0.60

571

048†

Low

1600

0.50

650

—

—

—

—

High

1600

0.65

720

060

Low

2000

0.15

900

Med**

2000

0.60

850

High

2000

0.65

945

LEGEND

ESP — External Static Pressure

IFM

— Indoor (Evaporator) Fan Motor

*Unit is factory set on medium speed, this airflow is not obtainable at

low speed.

†Size 048 has low and high speed only.

**460 volt motors do not have a medium speed.

NOTE: Values for 208/230-v motors are at 230 v; deduct 10% for 208 v.

A. For 208/230-v Blower Motors:

The motor leads are color-coded as follows:

3-SPEED

2-SPEED

black

=

high speed

black

=

high speed

blue

=

medium speed

red

=

low speed

red

=

low speed

To change the speed of the blower motor, remove the fan mo-

tor speed leg lead from the indoor (evaporator) fan relay (IFR)

and replace with lead for desired blower motor speed. Insu-

late the removed lead to avoid contact with chassis parts.

B. For 460-v (2-Speed) Blower Motors:

The motor leads are color coded as follows:

black

=

high

yellow

=

jumper

purple

=

jumper

red

=

low

To change the speed of the blower motor from low speed to

high speed, remove the red lead from the indoor fan relay

(IFR). Insulate the red lead to avoid contact with any chassis

parts. Separate the black lead from the purple jumper. Con-

nect the black lead to the IFR. Insulate the purple lead to

avoid contact with any chassis parts.

—13—