Troubleshooting the lock-n-load, Press, Shell plate troubleshooting – Hornady Lock-N-Load Ammo Plant User Manual

Page 50: Troubleshooting

Troubleshooting the Lock-N-Load

®

Ammo Plant

Tips for Trouble-Free Operation of the Lock-N-Load

®

AP

™

Press

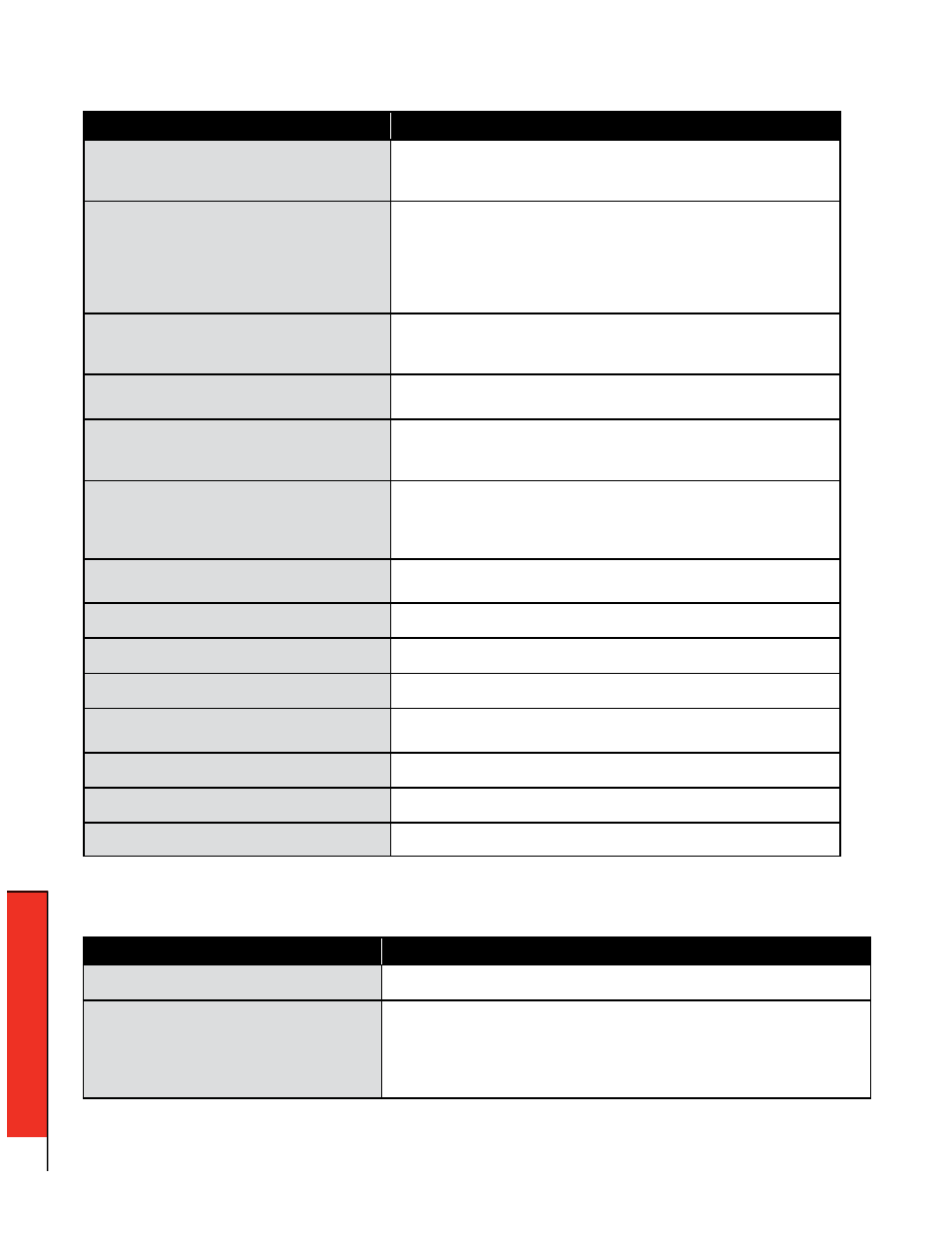

Problems

Solutions

Powder dropping around case

• Correct bushing in place?

• Powder drop tube and measure adapter clean?

• Bushing installed deep counter sink side up?

No primer in case

• Primer slide properly adjusted?

• Correct primer punch installed?

• Primer slide spring in place?

• Correct primer slide installed?

• Primer body rotated counterclockwise when installed?

• Primer housing tube too tight?

Shell Plate will not advance or does not index on station

• Primer not fully seated?

• Pawls correctly adjusted?

• Make sure you have the latest shell plate version with the groove on the bottom side.

Cases do not feed into Dies

• Die mouths beveled? (If not, return to manufacturer for repair.)

• Pawls timed correctly?

Gun powder is sticking in the powder measure, or

inconsistent charge weights

• Is the inside surface dry and clean?

• Try pouring a little powdered graphite thru the powder measure for lubricant.

Rub the outside of the powder hopper with a dryer sheet to eliminate static.

Case retainer spring won’t fall off the shell plate

or it is getting kinked

• Is there a burr on the shell plate where the spring groove and the case location meet?

• Is there a burr on the sides of the slot on the sub-plate? (With a

casefeeder, when you are setting up the timing, do not run the

case into the spring if the spring is up on the shell plate.)

Cases are hitting the back corner of the shell plate when

feeding into the shell plate

Slow timing down or readjust V-Block location

Cases are not feeding into the shell plate far enough

Speed timing up or using the wrong V-Block

Cases are tipping when going into the shell plate

Readjust V-Block location

Cases are falling on top of the V-Block

Readjust the bracket, square tubing

Drop tube is tight against the AP frame; will not allow

changing of tubes

Readjust the bracket, square tubing

Cases are falling mouth first out of the bowl

Close the door adjustment

Cases are getting caught in the open hole on the bowl

Open the door adjustment

The shell plate is hitting the V-Block when it’s rotating

Lower the cam wire

Shell Plate Troubleshooting

Problems

Solutions

Timing is severely out of adjustment

The Index Pawls may have been damaged

The Shell Plate does not rotate freely after mounting

• You may be trying to use the wrong version of shell plate. Your shell plate must have a groove

cut on the bottom side.

• Dirt or debris between the shell plate and the drive hub

• The Ball Detent bodies are not below flush on the underside of the Shell Plate.

• The Shell Plate is warped or damaged

*If you reach a point where you cannot get the press to work, please call our technical service staff at 800-338-3220 or send email to hornady.com/contact_us.

- 50 -

TROUBLESHOOTING

TROUBLESHOOTING