Rubicon Express RE7500 SERIES User Manual

Page 5

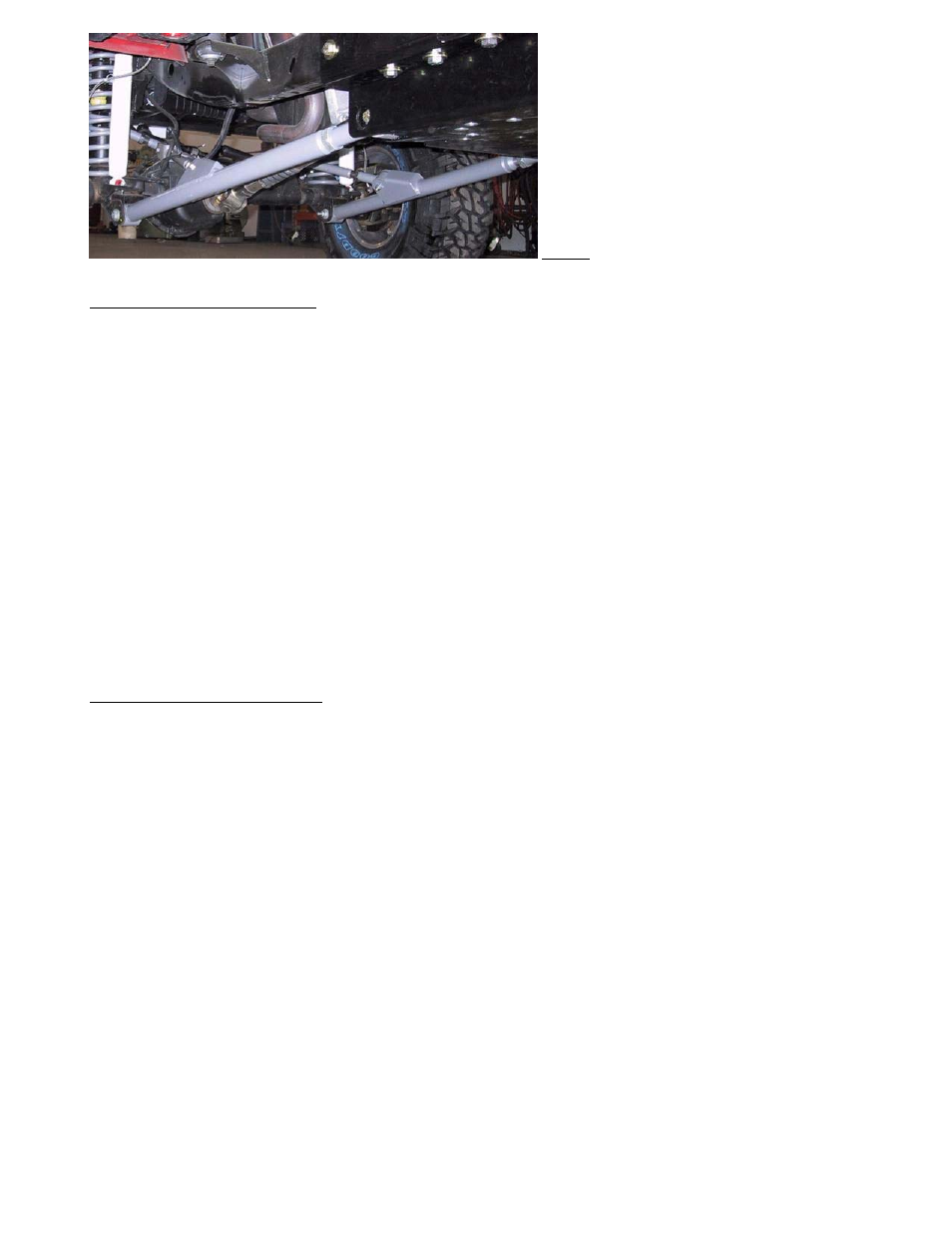

Photo 9

Step 4 – Rear truss assembly

A. With the upper control arms removed and axle lowered, sand the top of the upper control arm brackets flat, removing the ears

from the top front edge. Next, sand the tabs on the outer edges of the brackets smooth with the bracket. Then drill out the hole

in the upper control arm mount to 7/16”. Refer to photo XXX.

B. Loosely pre-assemble the rear truss assembly attaching the left and right control arm brackets, upper pivot support and the

correct differential cover bracket. The rear truss kit includes both the D35 and D44 cover bracket. You will need to select the

correct differential cover bracket from the kit for your vehicle. Refer to photo XXX.

C. Remove the upper three differential cover bolts and lower the truss assembly over the upper control arm brackets. Insert the two

upper bolts through the control arm brackets, using the supplied 5/16”x1” bolts, align the rear cover bracket and lightly tighten

the bolts. Tighten the two ½” bolts that go through the control arm brackets and main truss. Mark and drill the four additional

holes on the control arm mounts. Refer to photo XXX.

D. Insert the 4 7/16” bolts thru the upper and lower holes in the brackets using the supplied spacers to keep the factory axle

brackets from collapsing. Once all hardware is installed, tighten all but the three of the upper pivot support brackets. Leave two

out and one just loose enough to swing the bracket out of position for easier upper link installation. Refer to photo XXX

NOTE: Do not install all of the upper pivot support bolts at this time. Leaving two bolts out and swinging the bracket out of the

way will assist in installing the upper link assembly. Once the assembly is in place and axle centered install and fully

tighten all hardware.

Step 5 – Rear arm installation

A. REAR - Adjust rear lower control arms’ length to an initial setting of about 32-5/8” from bolt center to bolt center. this

measurement will be 42.625”. Final arm lengths seem to vary from around 32-5/8” to 33.25” depending on lift, axle squareness

(see step F), tire size, and gas tank clearance. Install adjustable end of arm to rear crossmember lower mounts with supplied

hardware (zerk on bottom).

LJ UNLIMITED - Adjust rear lower control arms’ length to an initial setting of about 42-5/8” from bolt center to bolt center. Final

arm lengths seem to vary from around 42-5/8” to 43-1/4” depending on lift, axle squareness (see step F), tire size, and gas tank

clearance. Install adjustable end of arm to rear crossmember lower mounts with supplied hardware (zerk on bottom).

B. UPPER TRI-LINK - Pre-assemble the two upper arms to the HD S/F ball assembly. Set both arms at an equal distance from the

center of end to center of end, approximately 34 ¼” - do not tighten the jam nuts at this time. It is very important that 1” of

thread contact be maintained between the upper arms and the pivot assembly.

C. Remove two of the bolts from the upper pivot support bracket and slide the upper arm link assembly into the upper control arm

pockets. Install supplied ½” x 4” bolts through the upper arm mount and mount support bracket.

D. Install 5/8” bolt through upper pivot support bracket and main truss to fully secure upper assembly. Refer to photo XXX.

E. Raise the axle into ride height position approximately 12”-13” distance between upper and lower spring cups. With a string line or

straight edge, measure axle center off the side of the frame down to the axle. Make sure that your axle measuring point is the

same on both sides. If your axle is off center to the driver’s side, lengthen the driver’s side arm and shorten the passenger’s side

arm or vice versa.

NOTE: Keep in mind that increasing or decreasing the length of the upper arm assembly will affect the pinion angle. Once

centered, and thread contact into the pivot assembly threads is confirmed, use the lower arms to fine-tune pinion

adjustment.

F. Once all adjustments are made, verify that all brackets are installed and hardware tightened.

RE7500A Page 5 of 8