Steele Products SP-PB113 User Manual

Page 6

WARNING! When servicing, use only replacement parts recommended by the

manufacturer of this tool. Use of any other parts may create a hazard or cause

product damage.

WARNING! Always wear safety goggles or safety glasses with side shields

during power tool operation or when blowing dust. If operation is dusty, also

wear a dust mask.

WARNING! Before performing any maintenance, make sure the tool is un-

plugged from the power supply and the switch is in the “OFF” position. Failure

to heed this warning could result in serious personal injury.

2. Remove the brush cap on the motor using a wide

ƀat blade screwdriver.

3. Pull out the brush. Repeat for the opposite side.

NOTE: If installing the existing brush or brushes, make sure the brush goes

in the same way it came out. Otherwise a break-in period will occur that will

reduce motor performance and increase brush wear.

4. Inspect the brushes for wear. On the wide

ƀat side of the brush is a wear

limit line. If the brush contact face is at or beyond (no line visible) the limit

replace brushes as a set.

5. Install the new brush. The two tabs on the brush terminal go in the same

hole the carbon part

ſts into.

6. Tighten the brush cap but do not overtighten.

WARNING! The brush cap is spring loaded by the brush assembly.

CARBON BRUSHES

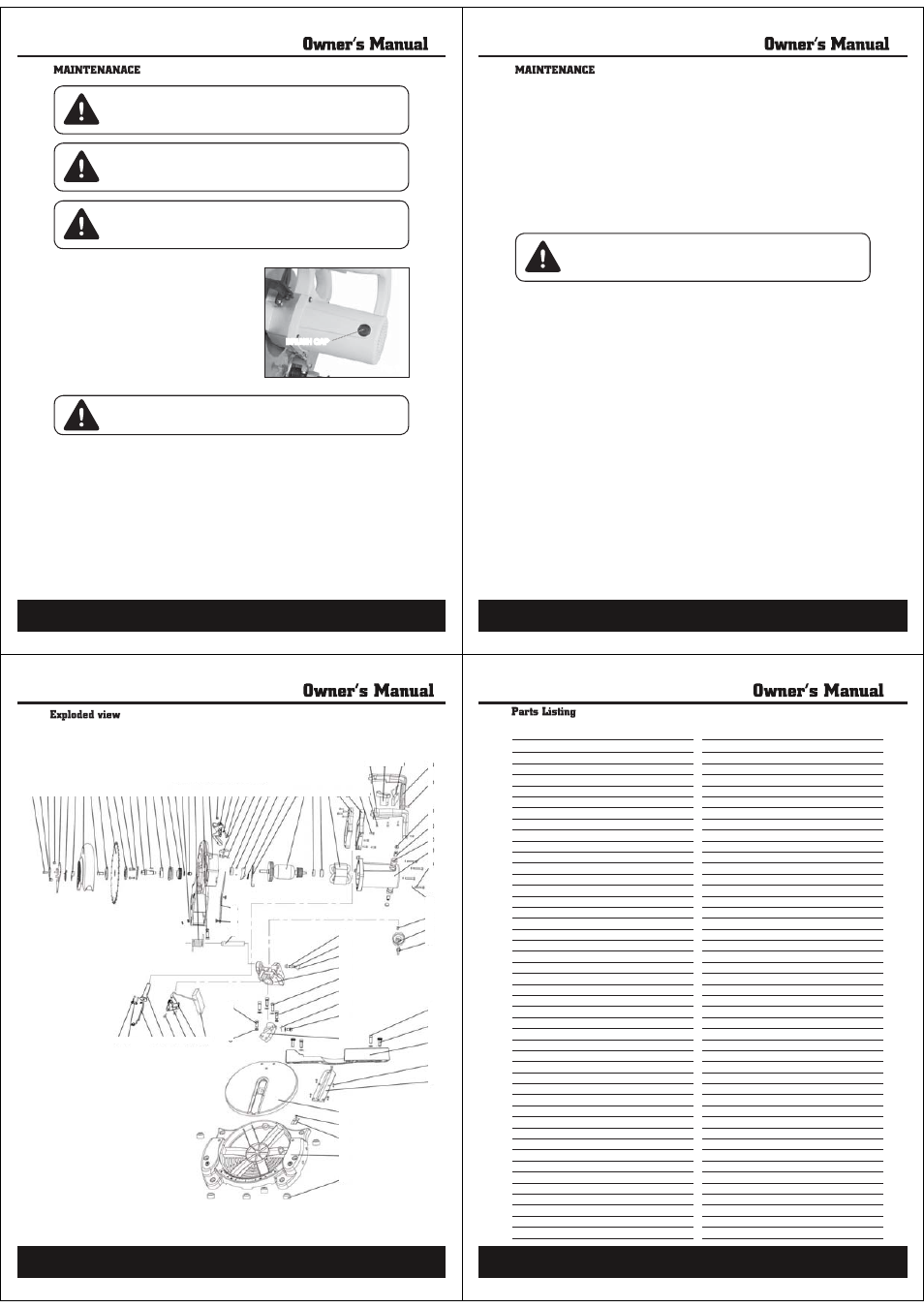

See Fig. 19.

The brushes and commutator in your

tool have been engineered for many

hours of dependable service. To main-

tain peak ef

ſciency of the motor, we

recommend every two to six months

the brushes be examined.

Motor Brush Replacement

To inspect or replace brushes:

1. Unplug the saw.

Fig.19

BRUSH CAP

GENERAL MAINTENANCE

1. Periodically check all clamps, nuts, bolts, and screws for tightness and con-

dition. Make sure the table insert is in good condition and in position.

2. Check the blade guard assembly.

3. Clean your cutting tools with a gum and pitch remover.

4. To maintain the table surfaces, periodically apply paste wax to them and buff

to provide smooth functioning. To prevent work from slipping during cutting

operations, DO NOT wax the working face of the miter gauge.

5. Protect the saw blade by cleaning out sawdust from underneath the saw

table and in the blade teeth. Use a resin solvent on the blade teeth.

6. Clean plastic parts only with a soft damp cloth. DO NOT use any aerosol or

petroleum solvents.

WARNING! Do not at any time let brake

ƀuids, gasoline petroleum-based

products, penetrating oils, etc., come in contact with the plastic parts. Chemi-

cals can damage, weaken or destroy plastic which may result in serious

personal injury.

LUBRICATION

This saw’s motor bearings have been packed at the factory with proper lubrica-

tion.

1. Clean the screw threads and nuts with a solvent recommended for gum and

pitch removal.

2. Lubricate the screw threads, nuts and bearing points (including those on the

blade guard assembly and miter gauge).

PLlEASE READ THE FOLLllOWING CAREFULLllY

The manufacturer and/or distributor has provided the parts list and assembly

diagram in this manual as a reference tool only. Neither the manufacturer or dis-

tributor makes any representation or warranty of any kind to the buyer that he or

UJGKUSWCNKſGFVQOCke an[TGRCKTUVQVJGRTQFWEVQTVJCVJGQTUJGKUSWCNKſGF

to replace any parts of the product. In fact, the manufacturer and/or distributor

expressly states that all repairs and parts replacements should be undertaken

by cer

VKſGFCPFNKEGPUGFVGEJPKEKCPs, and not by the buyer. The buyer assumes

all risk and liability arising out of his or her repairs to the original product or

replacement parts thereto, or arising out of his or her installation of replacement

parts thereto.

1

3

2

4 5 6

8

7

9 10 11 12 13 14 15 16 17 18 19 22 21 22 23 24 25 26 27 28 29 30 31 32 33 34

35 36 37 38 39 40

41 42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

78

90

89

88

87

86

85

84 83

79

80

81

82

68

69

70

71

72

73

74

75

76

77

APA Parts No. No. Description

QTY

APA Parts No. No. Description

QTY

PB113 -01-ZY

PB113 -02-ZY

PB113 -03-ZY

PB113 -04-ZY

PB113 -05-ZY

PB113 -06-ZY

PB113 -07-ZY

PB113 -08-ZY

PB113 -09-ZY

PB113 -10-ZY

PB113 -11-ZY

PB113 -12-ZY

PB113 -13-ZY

PB113 -14-ZY

PB113 -15-ZY

PB113 -16-ZY

PB113 -17-ZY

PB113 -18-ZY

PB113 -19-ZY

PB113 -20-ZY

PB113 -21-ZY

PB113 -22-ZY

PB113 -23-ZY

PB113 -24-ZY

PB113 -25-ZY

PB113 -26-ZY

PB113 -27-ZY

PB113 -28-ZY

PB113 -29-ZY

PB113 -30-ZY

PB113 -31-ZY

PB113 -32-ZY

PB113 -33-ZY

PB113 -34-ZY

PB113 -35-ZY

PB113 -36-ZY

PB113 -37-ZY

01

02

1

1

1

1

1

1

1

1

1

1

1

2

1

1

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

SCREW (M5X20)

1

SOCKET HEAD SCREW M8X12

BIG WASHER

SCREW M6X12

LOCATING PLATE

SPRING

GUARD COVER

PRESSBOARD SCREW M8X16-L

UPPER PRESSBOARD

SAW BLADE

LOWER PRESSBOARD

SCREW M6X12

BEARING PRESSBOARD

OUTPUT SPINDLE

WOODRUFF KEY

1

BEARING 6203

1

GEAR BOX COVER

1

1

BIG GEAR

1

CIRCLIP FOR SHAFT

ĭ17

SCREW M4X10

2

SLIDING BEARING

1

BIG SPRING

1

STRETCHING SCREW

1

SAW COVER

1

LOCKNUT M6

1

CONTROL KNOB

1

SPRING

1

SCREW

1

CONTROL KNOB SEAT

1

SCREW M5X14

2

BEARING 6201

1

SCREW M4X10

1

SELFT-LOCKING PRESSBOARD

1

SPRING

1

SELF-LOCKING POLE

1

ROTOR

1

PB113 -38-ZY

38 BEARING 629

1

WASHER

PB113 -46-ZY

PB113 -47-ZY

PB113 -48-ZY

PB113 -49-ZY

PB113 -50-ZY

PB113 -51-ZY

PB113 -52-ZY

PB113 -53-ZY

PB113 -54-ZY

PB113 -55-ZY

PB113 -56-ZY

PB113 -57-ZY

PB113 -58-ZY

PB113 -59-ZY

PB113 -60-ZY

PB113 -61-ZY

PB113 -62-ZY

PB113 -63-ZY

PB113 -64-ZY

PB113 -65-ZY

PB113 -66-ZY

PB113 -67-ZY

PB113 -68-ZY

PB113 -69-ZY

PB113 -70-ZY

PB113 -71-ZY

PB113 -72-ZY

PB113 -73-ZY

PB113 -74-ZY

PB113 -75-ZY

1

1

1

2

2

2

2

1

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

SWITCH

CAPACITANCE 0.33UF

HANDLE 4

SELF-TAPPING SCREW ST4X14

BRUSH HOLDER CAP

CARBON BRUSH

BRUSH HOLDER

HOUSE

SCREW M6X30

4

PLANE WASHER

4

SCREW M5X12

1

1

HANDLE OF BENDED ARM

1

SCREW

SHAFT

1

O-RING

ĭ6.7X ĭ1.8

1

LOCKING SHAFT KNOB

1

BENDED ARM

1

SCREW M8X30

3

NUT M6

1

BENDED ARM FINGER

1

SCREW M5X8

1

BASE OF BENDED ARM

1

SCREW M12X21

2

SOCKET HEAD SCREW M8X30

2

BACKBOARD

1

SUNK SCREW M4X10

5

PROTECTIVE BOARD FOR SAW BLADE 1

SWIVEL TABLE

1

SCREW

1

FINGER

1

PB113 -76-ZY

76 BASE

1

PB113 -77-ZY

77 FOUNDATION

6

PB113 -78-ZY

78 LOCKNUT M6

1

PB113 -79-ZY

79 STRETCHING SCREW M6X20

1

PB113 -80-ZY

80 SPINDLE

1

PB113 -81-ZY

81 SCREW & COVER

2

PB113 -82-ZY

82 HANDSPIKE

1

PB113 -83-ZY

83 BATTERY COVER

1

PB113 -84-ZY

84 LASER

1

PB113 -85-ZY

85 LASER HOLDER

1

PB113 -86-ZY

86 BATTERY COVER SCREW

2

PB113 -87-ZY

87 CABLE JACKET

1

PB113 -88-ZY

88 CABLE

1

PB113 -89-ZY

89 CABLE PRESSBOARD

1

PB113 -90-ZY

90 CABLE PRESSBOARD SCREW

2

PB113 -39-ZY

PB113 -40-ZY

PB113 -41-ZY

PB113 -42-ZY

PB113 -43-ZY

PB113 -44-ZY

PB113 -45-ZY

39

40

1

1

1

8

3

1

41

42

43

44

45

BEARING COVER

1

STATOR

HANDLE 1

HANDLE 2

SELF-TAPPING SCREW ST4X20

SELF-TAPPING SCREW ST4X20

HANDLE 3