Steele Products SP-PB113 User Manual

Page 4

Rating ..................................................................... 120 V, 60 Hz, AC Only, 15 A

No Load Speed .................................................................................. 4500 /min.

Blade Diameter ............................................................................. 10” (254 mm)

Blade Arbor .................................................................................... 1” (25.4 mm)

Cutting Capacity 90

º x 90º .................................................... 2-15/16” x 5-1/3”

90

º x 45º...................................................... 2-15/16” x 3-3/4”

45

º x 90º.......................................................... 1-1/3” x 5-1/3”

45

º x 45º.......................................................... 1-1/3” x 3-3/4”

Net weight ............................................................................................. 24.2 lbs

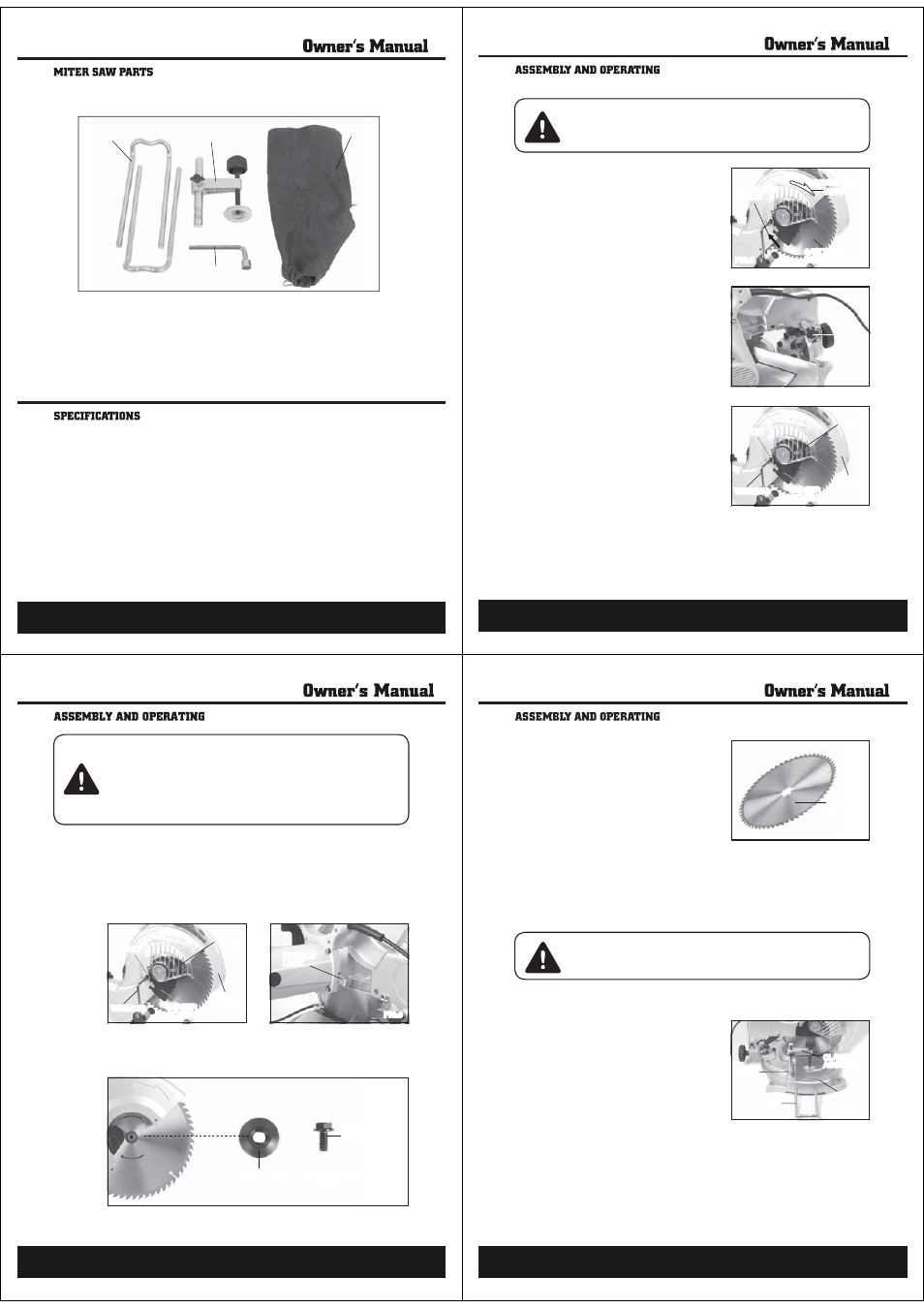

Fig. 4 illustrates all the loose parts packed with the saw.

13

1

2

3

4

Key No.

Description

Qty

1

Extension Bar

2

2

Work Clamp

1

3

Dust Bag

1

4

Socket Wrench

1

14

SAFETY RULES

1. When replacing the Saw Blade,

make sure the new Saw Blade has a

diameter of 10”, an RPM rating of

at least 7000, and an arbor hole of

1” diameter.

2. DOWN When installing a Saw Blade,

make sure the teeth of the Saw Blade

point downward, and that the direc-

tion of the arrow shown on the Saw

Blade matches the direction of the

arrow shown on the Cover Case. (See

Figure 5.)

3. Lock the Saw Blade in its upward

position. To do so, pull out on the

Cross Pin. Raise and hold the Cover

Case of the Miter Saw fully upward.

Turn the Cross Pin 90 degrees. Then,

insert the Cross Pin into the deep slot

in its locked position. (See Figures 6

and 7)

WARNING! Prior to performing any assembly and/or adjustment procedures,

make sure the Power Cord of the Miter Saw is unplugged from its electrical

outlet. Make sure the unit has completely cooled, and wear heavy-duty work

gloves.

COVER CASE

ARROW

SAW TEETH

POINTING DOWN

SAW BLADE

ARROW

FIG.5

FIG.6

PIN

SCREW

SAFETY

COVER

LARGER

COVER

WRENCH

BOLT

FIG.7

15

CAUTION! The Cross Pin should always be activated in the “locked

down” position when the Saw is not being used and when the Saw is

being transported. The Cross Pin should be activated in the “locked up”

position only when changing Saw Blades. NEVER use the Cross Pin in

any cutting operation. The Cross Pin allows the operator to lock the Saw

Blade in position, preventing the Saw Blade from being raised or lowered. (See

Figures 6 and 7.)

4. Loosen the Screw that holds the Large Cover in place. Then, use the Wrench

to remove the Bolt. (See Figure 8.)

5. Rotate the Large Cover and Safety Cover up and out of the way. (See Figure

8.)

6. Depress the Spindle Lock to keep the Saw Blade from turning. (See Figure

9.)

7. Use the Wrench to unscrew and remove the Spindle Bolt. NOTE: The

Spindle Bolt unscrews in a clockwise direction. Then, remove the Outer

Flange. (See Figure 10.)

SCREW

SAFETY

COVER

LARGER

COVER

WRENCH

BOLT

FIG.8

FIG.10

FIG.9

SPINDLE

LOCK

OUTER FLANGE

COUNTERCLOCKWISE

TO TIGHTEN

SPINDLE BOLT

CLOCKWISE

TO LOOSE

16

8. Release pressure on the Spindle Lock.

(See Figure 9.)

9. Wearing heavy duty work gloves to

avoid accidental cuts, remove the old

Saw Blade. (See Figure 11)

10. Install the new Saw Blade, make

sure the teeth of the Saw Blade

are pointing downward. (See Figure

5)

11. Reassemble the Outer Flange, and

5RKPFNG$QNVſrmly. (See Figure 10)

12. Swing the Large Cover and Safety Cover back in place, make sure the

Safety Cover covers the Saw Blade. (See Figure 8)

13. Reinstall the Bolt, and retighten the Screw. (See Figure 8)

14 . Make sure the Safety Cover returns to its original position prior to operating

the Miter Saw.

CAUTION! Make sure to pull out on the Cross Pin. Turn the Cross Pin 90 de-

grees. Then, insert the Cross Pin into the shallow slot in its unlocked position.

NEVER use the Cross Pin in any cutting operation. (See Figure 6.)

TO ASSEMBLE ADDITIONAL ACCESSORIES

1. A workpiece Clamp Assembly can

be installed by inserting the As-

sembly into the hole located in the

Guide Fence. Once inserted, lock the

Assembly in place with the Thumb

Screw. To clamp the workpiece to the

Base of the Miter Saw, turn the Ad-

justing Knob on the Clamp Assembly

clockwise. (See Figure 12.)

2. A workpiece Holder can be inserted

into each side of the Base, adjusted

for the desired length. The Holders should be used as supports when cutting

longer length workpieces. (See Figure 12.)

FIG.12

CLAMP

ASSEMBLY

BASE

HOLDER

GUIDE

FENCE

FIG.11

SAW

BLADE