Accessories, Troubleshooting, Head assembly diagram – Steele Products SP-PB208 User Manual

Page 7

Lubrication

All bearings are packed with grease at the factory and require no further lubrication. After use, remove

all swarf from the machine and thoroughly clean all surfaces.Components should be dry,with machined

surfaces lightly oiled. Always remove drill bits, and store in a safe place.

ACCESSORIES

USE ONLY ACCESSORIES THAT ARE RECOMMENDED BY THE MANUFACTURER FOR YOUR MODEL.

ACCESSORIES THAT MAY BE SUITABLE FOR ONE TOOL MAY BECOME HAZARDOUS WHEN USED

ON ANOTHER TOOL.

ALWAYS ATTACH GROUNDED (3-PRONG) EXTENSION CORDS TO GROUNDED

(3-PRONG) OUTLETS.

IF YOU MUST USE AN EXTENSION CORD, BE SURE THAT THE GAUGE IS LARGE ENOUGH TO CARRY

THE AMOUNT OF CURRENT NECESSARY FOR YOUR POWER TOOL. IF NOT, YOUR TOOL MAY

EXPERIENCE A LOSS OF POWER, EXCESSIVE VOLTAGE DROP OR OVERHEATING. FOR EXAMPLE,

THE SMALLER THE GAUGE NUMBER, THE HEAVIER THE CORD.

TROUBLESHOOTING

Noisy? Review the probable cause and remedy:

A) Incorrect belt tension

A) Adjust tension operation

B) Dry spindle

B) Remove spindle / quill assembly and lubricate

C) Loose pulley lubricate

C) Tighten Pulley

D) Worn bearing

D) Replace bearing

Excessive drill wobble? Review the probable cause and remedy:

A) Loose chuck

A) Tighten by pressing chuck down on to

a block of wood against the table.

B) Worn spindle or bearing

B) Replace spindle shaft or bearing

C) Worn chuck

C) Replace chuck

D) Bent drill bit

D) Replace drill bit

Motor won't start? Review the probable cause and remedy:

A) Power supply

A) Check power cord/fuse start

B) Motor connection

B) Check motor connections

C) NVR switch connections

C) Check switch connections

D) Faulty Switch

D) Replace switch

E) Motor Windings Burned

E) Replace Motor

Drill Bit Binds in Workpiece? Review the probable cause and remedy:

A) Excessive Feed Pressure

A) Apply less pressure

B) Loose Belt

B) Check Belt tension

C) Loose Drill Bit

C) Tighten drill bit with key

D) Incorrect drill speed

D) Refer to Cutting Speed chart, and

adjust drill speed accordingly

Table difficult to raise? Review the probable cause and remedy:

A) Needs lubrication

A) Lubricate with light oil

B) Table lock tightened

B) Loosen clamp

13

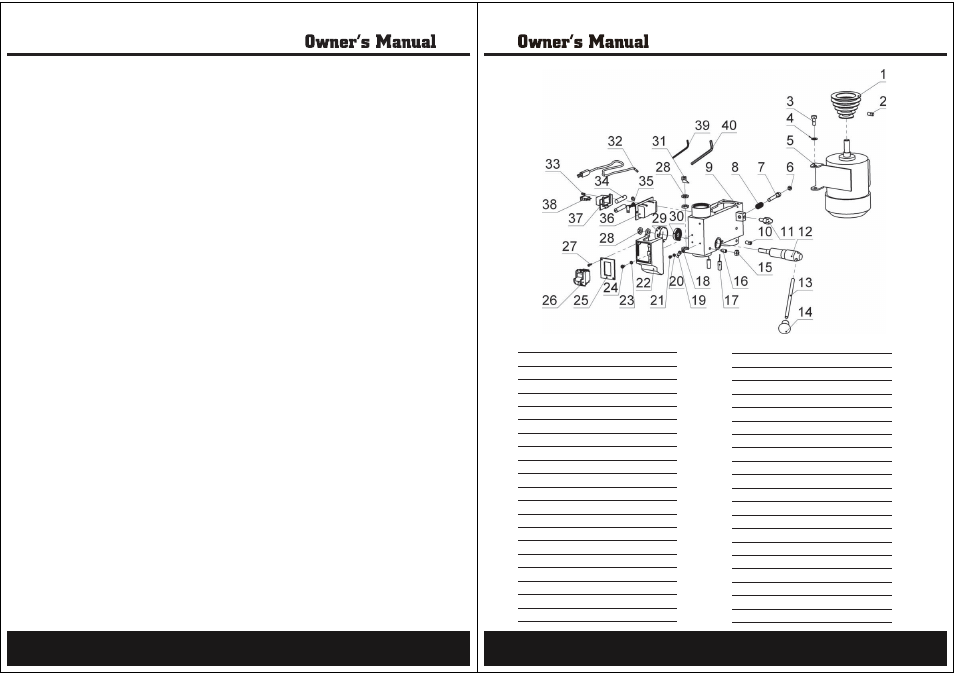

HEAD ASSEMBLY PARTS LIST

HEAD ASSEMBLY DIAGRAM

14

Motor Pulley

Screw

Bolt

Flat Washer

Motor

Rubber pad

Motor adjusting bar

Spring

Machine body

Screw

Locking knob

Gear shaft

Operating Handle

Knob

Nut

Screw

Laser guide

Teeth washer

Earth terminal

Elastic washer

APA Parts No.

No.

Description

PB208 -01-HY

PB208 -02-HY

PB208 -03-HY

PB208 -04-HY

PB208 -05-HY

PB208 -06-HY

PB208 -07-HY

PB208 -08-HY

PB208 -09-HY

PB208 -10-HY

PB208 -11-HY

PB208 -12-HY

PB208 -13-HY

PB208 -14-HY

PB208 -15-HY

PB208 -16-HY

PB208 -17-HY

PB208 -18-HY

PB208 -19-HY

PB208 -20-HY

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

Screw

Switch box

Flat washer

Screw

Switch plate

Switch

Screw

Nut

Spring cap

Spring

Pointer

Cable and plug

Screw

Battery

Electric polarity

Battery box

Battery box plate

Switch for laser guide

Allen key

Allen key

APA Parts No.

No.

Description

PB208 -21-HY

PB208 -22-HY

PB208 -23-HY

PB208 -24-HY

PB208 -25-HY

PB208 -26-HY

PB208 -27-HY

PB208 -28-HY

PB208 -29-HY

PB208 -30-HY

PB208 -31-HY

PB208 -32-HY

PB208 -33-HY

PB208 -34-HY

PB208 -35-HY

PB208 -36-HY

PB208 -37-HY

PB208 -38-HY

PB208 -39-HY

PB208 -40-HY

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40