Specific safety rules and/or symbols symbols, Important safety instructions, Components – Steele Products SP-PB208 User Manual

Page 4

BEFORE USING THIS TOOL, YOU NEED TO BECOME FAMILIAR WITH ITS OPERATION. IF YOU

ARE UNSURE ABOUT THE OPERATION OF THE TOOL, OR HAVE ANY QUESTIONS ABOUT ITS

PROPER USE, CALL THE CUSTOMER SERVICE DEPARTMENT AT 1-888-896-6881.

FOLLOW THESE INSTRUCTIONS FOR SAFE HANDLING OF THE TOOL:

Always secure and support the work piece using clamps.Do not use your hands to hold the piece

in place.

Be sure your work area is clean and secure before turning the power switch into the“ON”position.

Be sure the area is free from all foreign material, nails, staples, or any other material.

Turn the drill“OFF”and unplug from the power source before making any changes or adjustments

to the drill.

Do not use solvents containing carbon tetrachloride, ammonia or acetone to clean the drill. Never

use gasoline,paint thinner,or other caustic chemicals that can damage the plastic parts of the tool.

Always use the appropriate safety gear when operating this drill. Including but not limited, to

goggles,dust mask or respirator. Always work in a well-ventilated area to reduce your exposure

to harmful chemicals and dust particles.

Keep hands away from the cutting area.

Do not reach under the work piece.

SPECIFIC SAFETY RULES AND/OR SYMBOLS

SYMBOLS

THE FOLLOWING SYMBOLS MAY BE USED ON YOUR TOOL. BE FAMILIAR WITH AND LEARN THE

SYMBOLS TO OPERATE THE TOOL SAFELY.

SYMBOL

NAME

DESCRIPTION

V

VOLTS

VOLTAGE (POTENTIAL)

A

AMPERES

CURRENT

HZ

HERTZ

FREQUENCY (CYCLES PER SECOND)

W

WATT

POWER

KG

KILOGRAMS

WEIGHT

ALTERNATING CURRENT

TYPE OF CURRENT

DIRECT CURRENT

TYPE OF CURRENT

ALTERNATING OR DIRECT CURRENT

TYPE OF CURRENT

EARTHING TERMINAL

GROUNDING TERMINAL

CLASS II CONSTRUCTION

DENOTES DOUBLE INSULATION

MIN

MINUTES

TIME

S

SECONDS

TIME

DIAMETER

SIZE OF DRILL BITS, GRINDING WHEELS, ETC.

NO LOAD SPEED

NO-LOAD ROTATIONAL SPEED

…/MIN

REVOLUTIONS PER MINUTE

REVOLUTIONS, SURFACE SPEED, STROKES, ETC. PER MINUTE

1,2,3…

RING SELECTOR SETTINGS

SPEED, TORQUE OR POSITION SETTINGS

IMPORTANT SAFETY INSTRUCTIONS

7

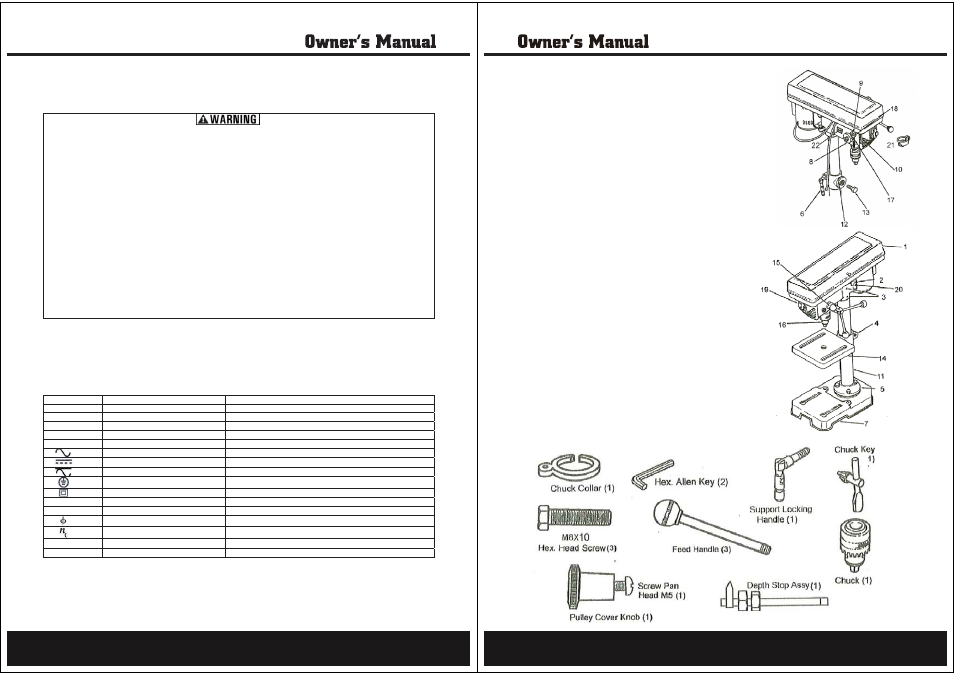

• 5 Speed Drill Head Assembly

• Table Assembly

• Base

• Column Assembly

• Assorted Loose Parts

COMPONENTS

1) Pulley Cover

2) Belt Tension Locking Screw

3) Head Lock Set Screws

4) Table Support

5) Column Support

6) Table Support Locking Handle

7) Base

8) Quill Spring Assembly

9) Pointer

10) Depth Scale

11) Column

12) Bevel Scale

13) Table Lock Set Screw

14) Table

15) Feed Handles

16) Chuck

17) Feed Stop Rod

18) Stop Nuts

19) Power Switch

20) Motor Stop

21) Chuck Collar

22) Laser Power Switch

ASSORTED LOOSE PARTS

PACKAGE CONTENTS

8