Wheels, Wheel configurations and uses, Industry color-coded system – Bosch 1810PS User Manual

Page 17: Ansi standard marking system, A30 t bf, Grinding, Type 1, Type 1a, Type 28, Type 29

167

Toll Free: 877-BOSCH-99

Boschtools.com

Grinding

Wheels

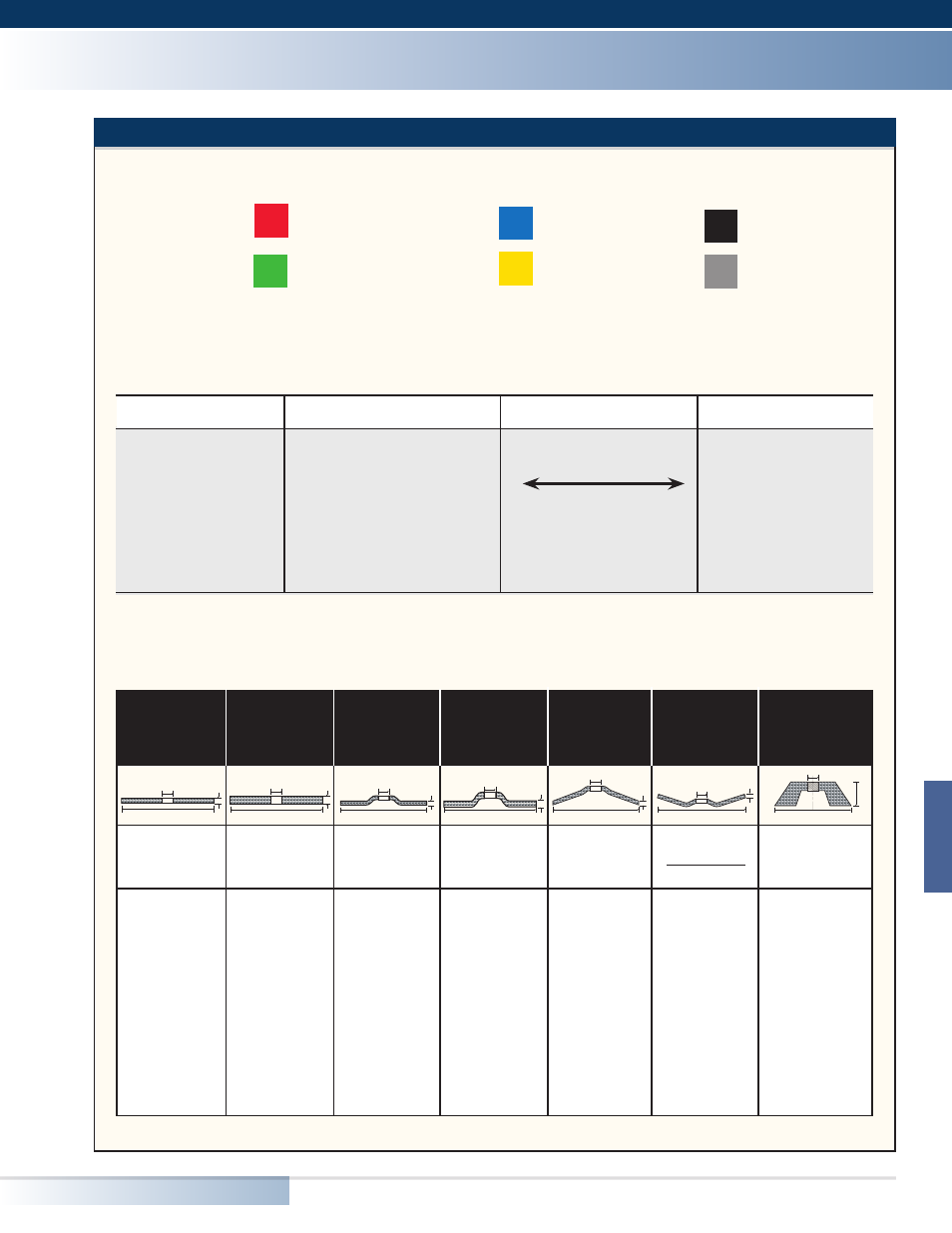

Wheel Configurations and Uses

Bonded abrasive wheels have different configurations depending upon the tool on which the wheel is used and the

desired end results. Below are the configurations that a wheel can have.

Industry Color-Coded System

Metal /

General Purpose

Aluminum

Stainless

Pipeline

Asphalt

Concrete /

Masonry

The following chart is an example of the ANSI standard marking system for identifying Bosch grinding wheels and other bonded abrasives:

Sample of typical marking:

A 30 T-BF

ANSI Standard Marking System

C

B

A

C

B

A

A

B

C

B

A

C

C

B

A

Bench or

Type 1

Used for edge

grinding at a

50°-90° angle.

Not for cutting

applications.

Type 1A

(ISO 41)

Used at a 90°

angle for

cutting only.

No grinding.

Type 1

GRINDING

Straight

Wheel

Type 1A

(ISO 41)

CUTTING

Straight

Wheel

Type 28

To be used

for weld

preparation

and de-burring

surfaces. Tool

usually used at

a 15° angle, to

cover greater

surface area

and allow

better visibility.

Type 29

For blending and

stock removal on

uneven surfaces,

best used at a

10° angle. This

allows user to

use one wheel

for grinding

and finishing.

Type 11 Steel-

Concrete

Used for removing

excess material

and build-up on

large flat surfaces,

allowing for

maximum surface

area coverage

– tool used

perpendicular

to work.

Type 28

GRINDING

Type 29

BLENDING

GRINDING

Type 11

GRINDING

A

C

B

Type 27

BLENDING

GRINDING

Type 27

For use on flat

surfaces for

weld prep,

usually on bar

stock or angle

iron. Tool best

used at a

30° angle. No

cutting.

Depressed

Center

Wheel

A

C

B

Type 27A

CUTTING

Type 27A

To be used at

a 90° angle

for light

cut-off work.

Depressed

Center

Wheel

Saucer-

shaped

Wheel

Flexible

Wheel

Flap Disc

Flared Cup

Wheel

A = Wheel diameter B = Wheel width or thickness C = Wheel bore

Primary Grain Used

to Make the Wheel

A = Aluminum oxide

AS = Aluminum oxide

special

C = Silicon carbide

CS = Silicon carbide

special

Z = Aluminum zirconium

Type of Bond Used

B ____ Resinoid

BF __ Resinoid Reinforced

Size of the Abrasive Grain

Very coarse

8-12

Coarse

14-24

Medium

30-60

Fine

70-180

Dust fine

200-800

Hardness of Bond

Soft

Medium

Hard

N

P

R

S

T

A

30

T

BF