Burnham SM-6 User Manual

Page 18

18

Use the Trouble Shooting Guide (pages 19 to 21) to

assist in locating where a malfunction in the control

system is occurring.

4

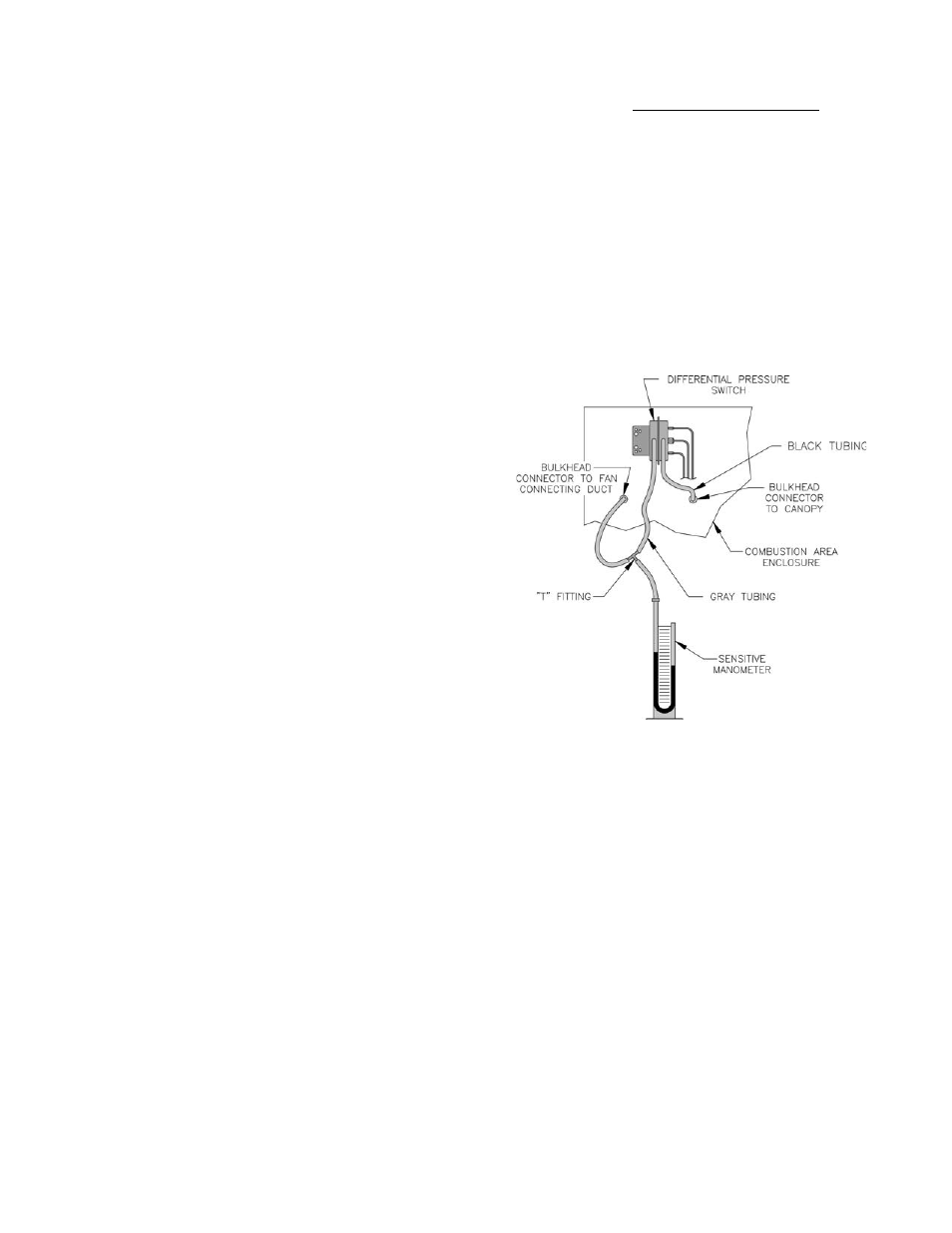

PROCEDURE FOR MEASURING FAN

DIFFERENTIAL PRESSURE (See Figure 13).

a. With boiler off, remove black silicone tubing from

low side of pressure switch.

b. With tee and ¼” aluminum stubs, connect

manometer as shown with additional tubing.

c. Start boiler and read differential pressure on

manometer. Should be -0.6” wc or greater (example

-0.7” wc).

d. Stop boiler, remove manometer and reconnect black

silicone tubing to duct.

5

CHECK GAS INPUT RATE TO BOILER

a. Input rate and maximum inlet pressure shown on

rating label must not be exceeded. Inlet pressure

must not be lower than minimum inlet pressure

shown on rating label.

b. All rate checks and all adjustments are to be made

while boiler is fi ring - all other appliances connected

to the same meter as the boiler must be off.

c. Water manometer or water column gauge should

be connected to a shutoff valve installed in the

1/8” pipe tapping in the gas valve - boiler off. By

installing gas valve up stream of manometer, gas

pressure can be introduced gradually - without

shutoff valve, surge of pressure when boiler is

turned on, could blow liquid out of manometer.

Replace plug in gas valve when rate check is

fi nished.

d. Approximate input - Adjust pressure regulator on

combination gas control so that manifold pressure is

equal to that shown on rating label. Determine what

TROUBLE SHOOTING

Figure 13

PROCEDURE FOR MEASURING FAN DIFFERENTIAL

PRESSURE

fl ow (cu. ft.) should be in 3 minutes using formula

below:

cu. ft. per = Btuh Input (from Rating Label)

3 min. = 20000

Clock gas meter for three (3) minutes using second

hand or stop watch.

For minor input changes readjust pressure regulator

on combination gas control. Increase or decrease

manifold pressure to obtain corresponding increase

or decrease in gas input.

Turning regulator adjusting screw clockwise

increases pressure. Counterclockwise rotation

decreases pressure. If it is necessary to increase

manifold pressure more than 0.3” of water to obtain

rated input, remove orifi ces and drill one size larger.

Reinstall and recheck input rate.