Iii. operating instructions – Burnham SM-6 User Manual

Page 13

13

Safe lighting and other performance criteria were met with

the gas manifold and control assembly provided on the

boiler when the boiler underwent tests specifi ed in ANSI

Z21.13.

1

INSPECT INSTALLATION BEFORE

STARTING.

2

INITIAL

START

a. FILL ENTIRE HEATING SYSTEM WITH

WATER and vent air from system. Vent air from

all heat distributing units and all high points in the

piping of the system. When venting air from system

keep fi ll valve in open position to maintain water

pressure. Make certain pressure reducing valve is

installed between the fi ll valve and the boiler. (See

Figure 7)

Use the following procedure on a series loop system

equipped with zone valves.

1. Close all but one zone valve.

2. Attach a hose to drain valve on purge fi tting and

extend hose to drain.

3. Open drain valve on purge fi tting.

4. Close purge valve.

5. Open relief valve on boiler.

6. Open fi ll valve.

7. When water discharges from relief valve, release

the lever on top of the relief valve, allowing it to

close.

8. Allow water to run out of drain valve until zone

has been purged of air and fi lled with water.

9. Open zone valve to the second zone to be

purged, then close the fi rst. Repeat this step until

all zones have been purged but always have one

zone open. At completion open all zone valves.

10. Close drain valve on purge fi tting.

11. Continue fi lling the system until the pressure

gauge reads 12 psi. Close fi ll valve.

NOTE: If make-up water line is equipped

with pressure reducing valve, system will

automatically fi ll to the set pressure of valve

(normally 12 psi). Leave globe valve open.

12. Open purge valve.

b. Set ROOM THERMOSTAT below room

temperature.

III. Operating Instructions

c. Be sure that gas to pilot and main burners has been

off for at least fi ve minutes.

d. Open valve on main gas line at meter.

e. PURGE AIR FROM GAS PIPING. During the

purge adequate ventilation must be provided and no

smoking or open fl ame permitted. (See Figure 10)

1. Open manual shutoff valve upstream of

combination gas valve.

2. Loosen or remove inlet pressure tap plug in

combination gas valve and when purging is

complete, tighten or replace plug.

3. Check pipe and fi ttings from meter to

combination gas valve using soap solution or

other approved methods.

f. TEST GAS PIPING — Test gas piping and

connections between combination gas valve and

manifold, manifold orifi ces, and pilot piping for

leaks after boiler is operating. Use soap solution or

other approved method.

g. Install enclosure cover and secure with #8 x ½” long

sheet metal screws.

3

OPERATING INSTRUCTIONS - See page 14.

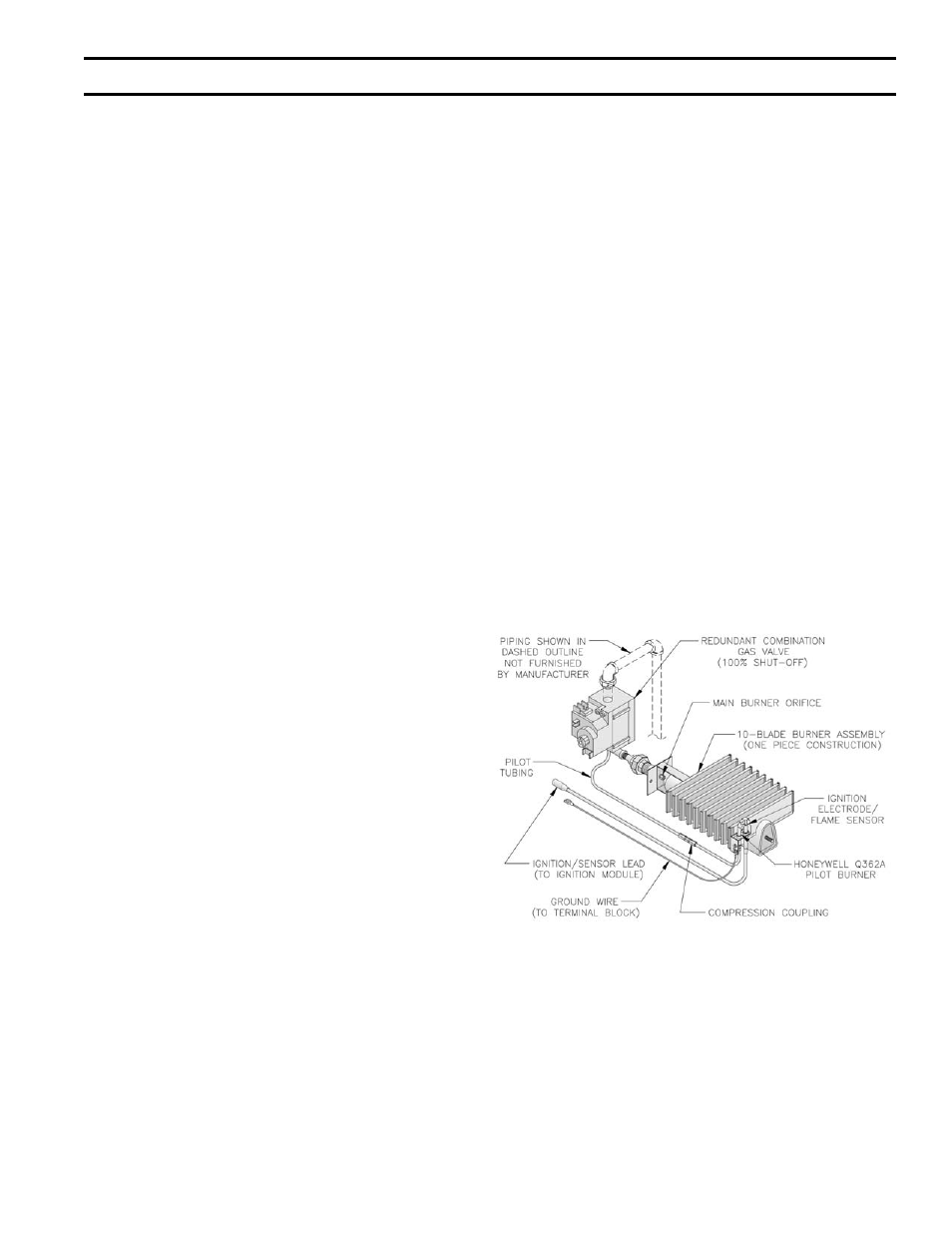

Figure 10

SCHEMATIC PILOT AND GAS PIPING