Troubleshooting suggestions – Bloomfield 2030 User Manual

Page 19

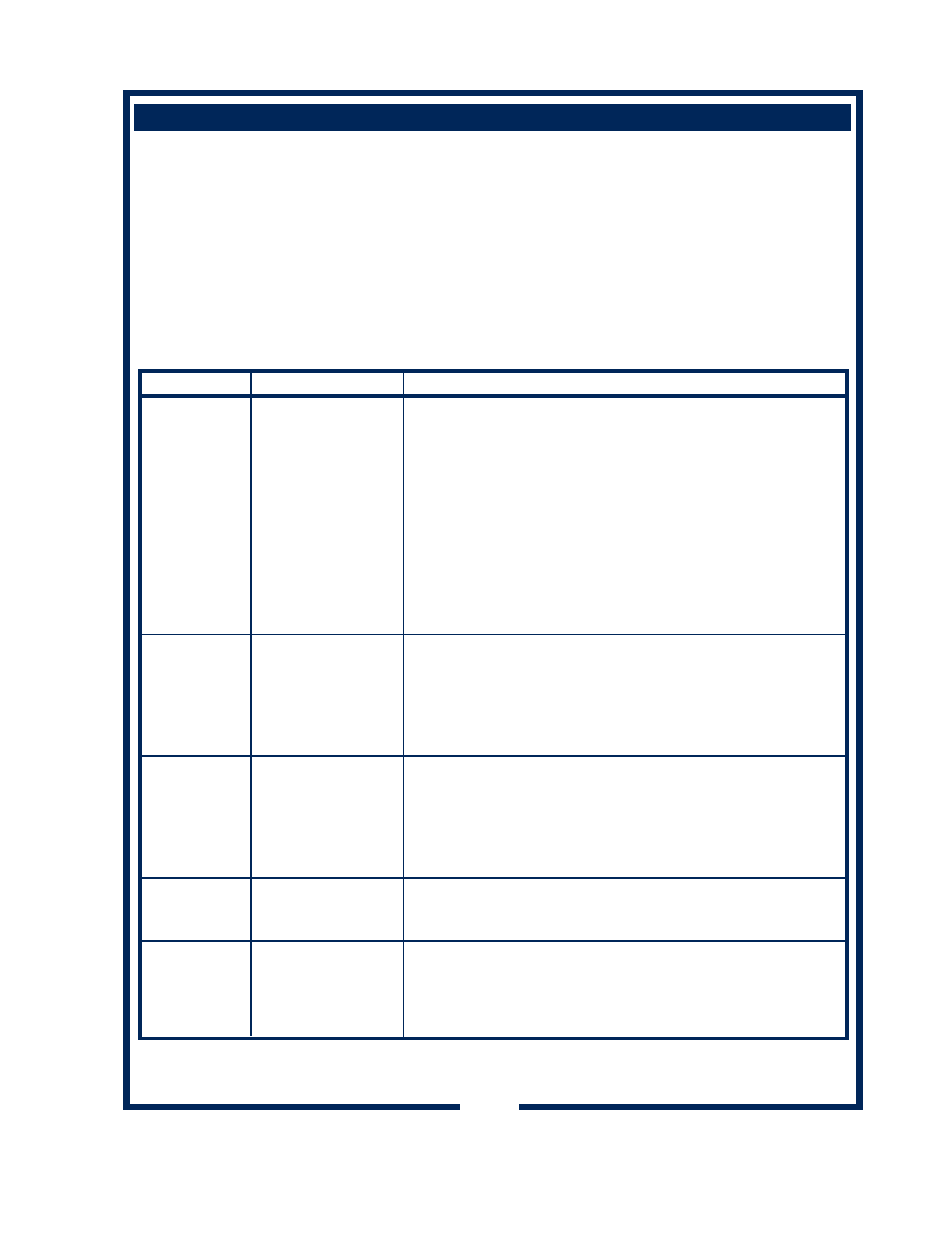

TROUBLESHOOTING SUGGESTIONS

If the E-Max T™ goes into the error mode as outlined below, it will likely be necessary to reset the

brewer in order to test individual components. Note the reset procedure below:

•

For the first four error modes, press and hold CANCEL for 3 seconds, or RE-ENERGIZE the

brewer by disconnecting from electric power for 5 seconds, then reconnecting.

•

From “VALVE FAULT”, the brewer must be RE-ENERGIZED! Using the CANCEL button will not

reset the brewer from “Valve Fault”.

The Test Program will also assist in isolating and testing specific components. As an example to test

the three main components in the heater system, go to the test program and proceed to turn the

“heater on”. Use a meter or test light to determine if power is getting to and from: the triac, the high

limit and the element.

ERROR MESSAGE

1. “Probe/Heater”

Error

RESET by

holding

CANCEL switch

for 3 seconds

2. “Overheat” Error

RESET by

holding

CANCEL switch

for 3 seconds

3. “No Water

Sensed” Error

RESET by

holding

CANCEL switch

for 3 seconds

4. “Keyswitch

Locked” Error

RESET as

above

5. “Valve Fault”

Error

RESET by

disconnecting/

reconnecting

electric power

CAUSE

Controller has turned

heating element on for 5

minutes without sensing a

+2ºF change in water

temperature.

Water temperature has

exceeded Maximum Water

Temperature programmed

into “Machine Settings”

menu.

Inlet valve energized but

no water is sensed during

regular operation for 60

seconds; or.

no water sensed during

start-up (manual or timed)

for 4½ minutes.

A switch on the keypad

has been held down for

more than 10 seconds.

Detection of a problem with

the valve switching system,

or with the wiring to the

valves.

SUGGESTIONS FOR REMEDIAL ACTION

1. Temp Probe may not be connected properly, or may be defective. CHECK &

CORRECT. To test probe, go to Test Program and view probe value. A value

of over 155 indicates a defective probe; a value of under 15 indicates a bad

connection of the probe to the board. With an ohmmeter measure resistance of

probe. At 212ºF, resistance is approx. 2,000

Ω. If less than 1800Ω at room

temperature

, probe is defective.

2. May be boiling due to high altitude (boiling point below Brew Temp.) or Triac

has failed ON and hi-limit has interrupted power to heating element. REDUCE

BREW TEMP. CHECK TRIAC; REPLACE IF DEFECTIVE.

3. Heating element defective. CHECK ELEMENT; REPLACE IF DEFECTIVE.

4. Hi-limit thermostat may be cutting out at too low a temperature. CHECK HI-

LIMIT THERMOSTAT; REPLACE IF DEFECTIVE. (Note; hi-limit will reset

itself if allowed to cool by 30ºF, making troubleshooting a challenge as the brewer

cools then functions normally.)

5. Heating element may be encrusted with lime or scale build-up. DELIME BREWER

AS DETAILED ON PAGE 16.

1. Brew Temperature may be set too close to Maximum Temperature. Brew

Temperature should be at least 5ºF below Maximum Water Temperature.

LOWER BREW TEMPERATURE or RAISE MAXIMUM TEMPERATURE

(Software versions after May, 1999 enforce the 5ºF differential)

2. Triac has failed ON; element continues to heat even when controller is OFF.

CHECK TRIAC; REPLACE IF DEFECTIVE.

3. Temp Probe defective. See probe test procedure in Item #1 above. CHECK

PROBE; REPLACE IF DEFECTIVE.

1. Sleeve on water level sensor is too long, or sensor is not pushed down fully.

Sensor should extend beyond sleeve a minimum of ¼” to a maximum of

l”.

REMOVE TANK LID, CUT SLEEVE TO PROPER LENGTH. ENSURE SENSOR

IS PUSHED DOWN ALL THE WAY.

2. Wiring to water level sensor disconnected or defective; or, sensor pulled out of

tank. CHECK & CORRECT.

3. Water level sensor may be encrusted with lime build-up. CLEAN SENSOR.

4. Water supply may be OFF. CHECK & RESTORE WATER SUPPLY.

1. Switch has been accidentally held for 10 or more seconds. RELEASE SWITCH

2. Defective keypad. PRESS & HOLD “CANCEL” FOR 3 SECONDS. Observe

brewer to determine if problem persists. (Note: available on software versions

MFW 275 Rev. 3.4 and later versions only).

1. Wiring to either inlet or outlet valve not properly connected. CHECK WIRING AND

CONNECTIONS.

2. The controller has two switches for each valve and one or both has been detected

as failing ON. (This prevents the brewer from operating unless both switches are

working properly.) REPLACE CONTROLLER.

17