Liebherr LTM 1220-5.2 User Manual

Page 9

700

9

4

LTM 1220-5.2

LTM 1220-5.2

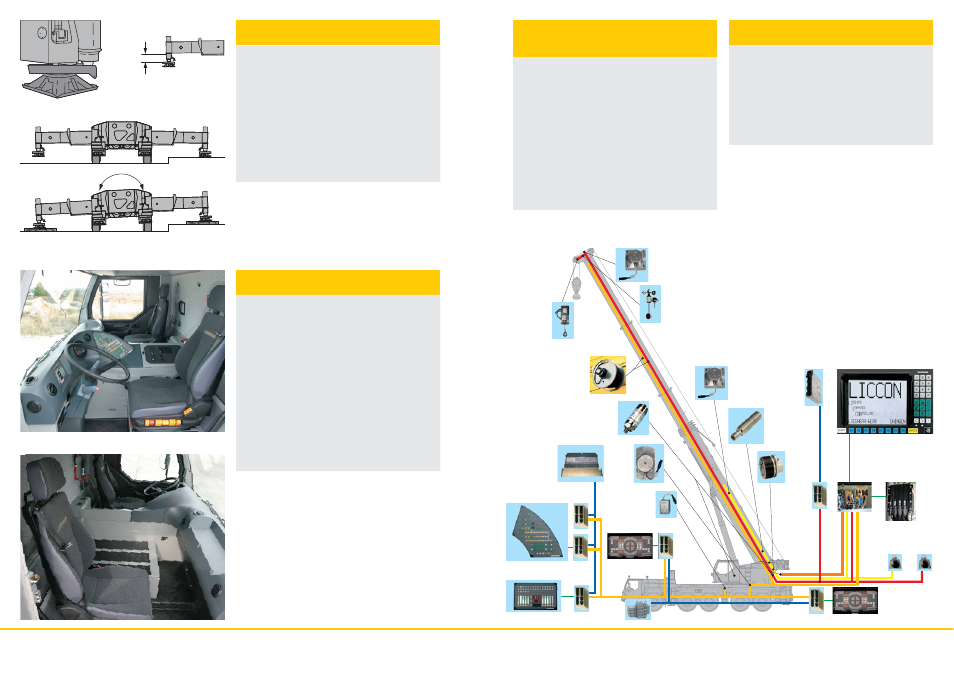

• Variable support basis

outriggers retracted

Support basis 5.5 m x 8.9 m

Support basis 8.3 m x 8.9 m

• Fix-mounted supporting pads with splash guard

• Supporting ram travel of up to 700 mm

• Level control of the outriggers, all-automatic push-button

crane levelling during the supporting procedure

• 2 x 9° lateral inclination of crane and crane superstructure

• Control panels at either side of the carrier with membrane

keyboard and electronic inclination indicator, push-buttons

for ENGINE/START/STOP and speed control are illuminated

and lockable

• Operation of the outrigger system in accordance with

accident-prevention legislation

• Illumination of the supporting area by 4 incorporated

projectors

Setting crane on outriggers –

quick, convenient and safe

• Modern, comfortable driver’s cab of high functionality and

convincing design, corrosion-resistant, sheet steel version,

cataphoretic dip-primed, front mounted on rubber shock

absorbers, rear cushioned hydraulically, internal sound and

heat absorbing panelling

• Safety glass all-round, greenish tinted front and side windows

for heat absorption, electric window lifters

• Arrangement of the control elements and displays according

to ergonomical aspects for safe and convenient handling

during continuous operation

• Digital display and keyboard units interconnected with the

functional blocks by data bus technology

• Driver’s seat cushioned pneumatically, with pneumatic lumber

support, headrest

• Steering wheel adjustable in height and inclination

• Heatable and electrically adjustable rear mirrors

• Safety belts for driver and co-driver

• 3 windscreen wipers with automatic wipe/wash system and

intermittent control

• Delayed switch-off of the interior lights

• Various racks and stackers

• Radio preparation

Comfortable driver’s cab

of high functionality

The Liebherr mobile cranes are entirely equipped with data

bus transfer systems. The digital system is the basis for the

data bus. It permits the transfer of a multitude of information

almost parallel and faultless via one only cable. Liebherr has

developed its own system bus (LSB) which corresponds to

the manifold requirements in respect to all possible mobile

crane operations. All important electrical and electronical

components on the superstructure, such as length sensors,

angle sensors, load cells, proximity switches, master switches

and hoist limit switch are equipped with their own

microprocessors and communicate via various data bus

networks. The keyboard and display units, the outrigger control

as well as the engine and transmission control on the vehicle

are intelligent function blocks and equipped with bus interfaces.

A continuous self-test of the sensors during operation

guarantees a high functional reliability. The internetworking of

the LICCON computer system with the system bus establishes

entirely new and comprehensive diagnostic facilities in respect

to the crane.

Data bus technique

revolutionises the

crane electric system

• Reduction of the operating costs due to a modern engine

and transmission management (CAN bus system); increased

economy due to improved endurance of the individual units

• Improved reliability due to a considerably reduced number

of electrical cables and contacts

• A continuous self-test of the „intelligent sensors“ guarantees

a maximum of reliability

• Comprehensive diagnostic facilities - quick error detection

• Self-manufactured bus systems, specially adapted to the

requirements of a mobile crane

• The data bus technique increases the comfort and safety

during driving and crane operation

The advantages of the

data bus technique at a glance