Liebherr LTM 1220-5.2 User Manual

Page 7

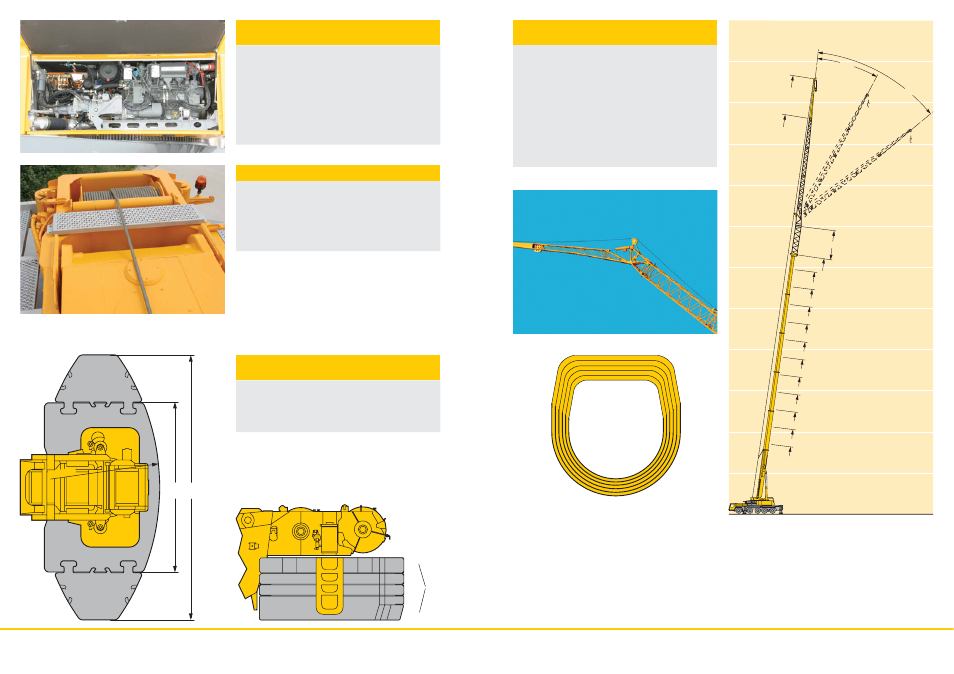

100 m

90 m

80 m

70 m

60 m

50 m

40 m

30 m

20 m

10 m

110 m

5630

10 t

R = 4850

3600

10 t

12 t

54 t

10 t

10 t

10 t

12 t

22,5°

45°

7

6

LTM 1220-5.2

LTM 1220-5.2

• Crane engine: 4-cylinder Liebherr turbo-charged diesel

engine type D934L A6 with 180 kW/245 hp, exhaust gas

emissions in accordance with the directives 97/68/EC Stage

3 and EPA/CARB Tier 3, robust and reliable, located opposite

the crane cab, thus lower noise emissions, electronic engine

management, optimized fuel consumption, stainless steel

exhaust gas system

• Hydraulic system with 5 axial-piston variable displacement

pumps with servo control and capacity regulation,

electronically-controlled oil cooler as standard

• Highly-efficient noise abatement of the diesel-hydraulic crane

drive as standard

Crane drive with

field-proven components

oviform boom profile

• Liebherr-built winches (hoist gear 1 and 2) with special

grooving, with integrated planetary gears and spring-mounted

multi-disc brakes as static brakes

• Liebherr-built axial-piston constant-output engine, specially

designed for crane operation, exposed successfully to tough

fatigue tests

• Display of the winch rotation on the LICCON screen

• Non-rotating hoist rope

Liebherr winch technology

• Counterweight variants 12 t, 22 t, 34 t, 44 t, 54 t and 74 t

• Control of ballasting from the crane cab

• Quick ballasting by “key-hole” method

• Ballasting cylinder permanently mounted to superstructure

• Compact counterweight dimensions, e.g. 54-t counterweight

of only 3.6-m width

Ballasting –

in a matter of minutes

• 6-section, 60-m-long telescopic boom with rounded, oviform

bottom shell for high lateral stability

• Optimal utilisation of the telescopic boom due to a multitude

of telescoping variants

• 12.2-m – 22-m-long biparted swing-away jib extendable to

29 m and 36 m

• Swing-away jib mountable at 0°, 22.5° and 45°, hydraulic

fitting aid, hydraulic ram for continuous variation of the

swing-away jib from 0° – 45° (optional)

• Telescopic boom extension 7 m, resulting in a 7-m higher

attachment point for the swing-away jib

• Quick and easy re-reeving of the hoist rope by rope dead

end connection

• Load hook with rope dead end connection, cylindrical load

hook shape for easy displacement by rolling on the ground

Lifting of loads -

precise and safe

K 29 m

K 36 m

60 m

7 m

56 m

52 m

47.7 m

43.4 m

39.1 m

34.8 m

30.5 m

26.2 m

21.9 m

17.6 m

13.3 m