Liebherr LTM 1220-5.2 User Manual

Page 10

3

10

LTM 1220-5.2

LTM 1220-5.2

Axles 3, 4 and 5 set up as „active rear-axle steering, 5 steering

methods are preselectable by fixed programs (P):

P1: On-road steering

Axles 1 and 2 are steered mechanically with hydraulic assistance

by the steering wheel. Axles 3, 4 and 5 are steered „actively“

speed-dependent, subject to the cramp of the front axles,

and over 30 km/h, axles 3 and 4 are set to straight displacement

and fixed, from 60 km/h, axle 5 is fixed equally to straight

displacement. The change of the steering angle in accordance

with the speed, results in a precise and stable driving quality

during higher speeds, tyre abrasion is reduced and the

maneuverability clearly improved.

P2: All-wheel steering

Axles 3, 4 and 5, dependent on the steering angle of axle 1

are cramped by means of the steering wheel so that the

smallest turning radii can be performed.

P3: Crab steering

Axles 3, 4 and 5 are cramped into the same direction as axles

1 and 2 by means of the steering wheel.

P4: Steering without swerving

Axles 3, 4 and 5 are cramped in accordance with axle 1 so

that no swerve out of the rear of the carrier takes place.

P5: Independent rear-axle steering

Axles 1 and 2 are cramped by the steering wheel, axles 3, 4

and 5 steered independent of the cramp of axles 1 and 2 by

momentary-contact buttons, whereby the cramp of axle 3 is

adapted to the required situation.

• A failure in the rear-axle steering makes it ineffective and

the rear axles are set to straight displacement by the centering

rams

• Two independent hydraulic circuits with wheel- and engine-

driven hydraulic pump, thus maximum safety standard

• Two independent control processors (by existing E/A modules)

and diversified sensoriel system

• Entire know-how of the „active rear-axle steering“ by Liebherr

Variable steering

concept with

„active rear-axle steering“

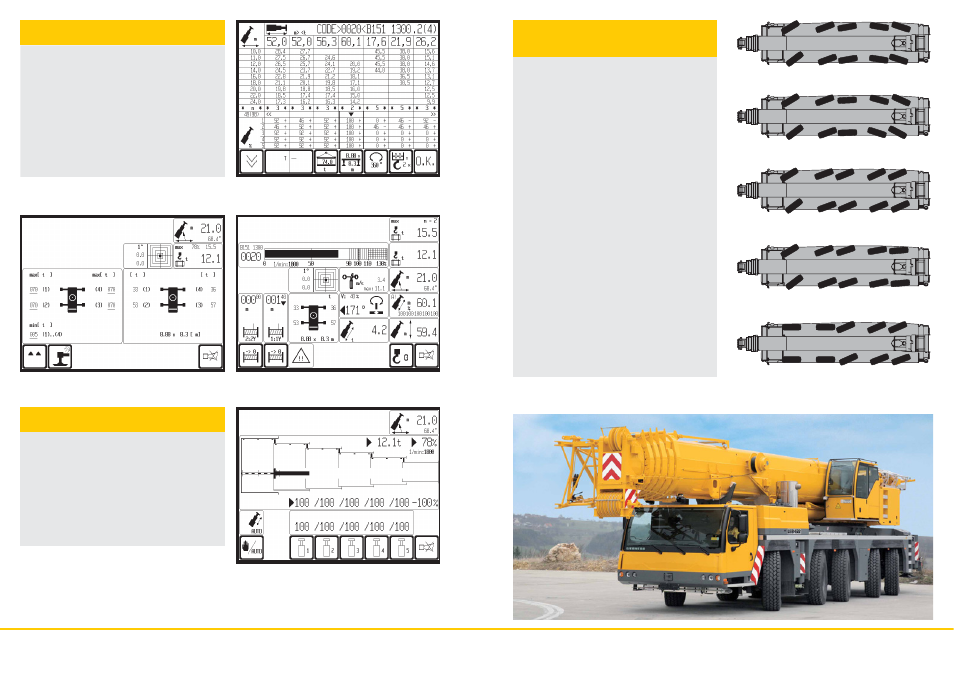

• Standard application programs: Safe load indicator (LMB),

configuration program with configuration picture, operation

program with operating picture, telescoping program with

telescoping picture, test parameter program, test system;

supporting force indication and work area limitation as an

optional feature

• Setting of the configuration program by convenient

interactive functions

• Safe and reliable acknowledgement of the configuration set

• Representation of all essential data by graphic symbols on

the operation picture

• With integrated wind force test (optional)

• Reliable cut-off device when exceeding the admissible

load moments

• Load capacity values for any boom intermediate length

• Winch indications for precise lifting/lowering of the load

LICCON configuration and

operation program

• Telescoping by single-stage hydraulic ram with hydraulic

driving tenons (patented internal interlocking system)

• Telescoping procedure controllable by convenient operator’s

guide on the monitor, precise approach of the interlocking

positions

• Telescopable loads are displayed on the LICCON

operating picture

• Rapid-cycle telescoping system with „automatic mode“, i.e.

all-automatic telescoping to the required boom length

• Very compact and light-weight telescoping system, thus

increased load capacities, especially with long booms and

large radii

• Automatic cushioning in end positions during telescoping

and retracting for the preservation of the structural members

LICCON-assisted

telescoping system