Pressing description and equipment technology – Liebherr LRB 155 User Manual

Page 2

2

Pressing

Description and equipment technology

The pressing process works with single sheet piles. The

sheet piles are friction-locked to the pressing cylinders

by clamps. Initially the sheet piles are pressed into the

soil via the rope crowd system, which already makes a

penetration of several metres possible. Thereafter, sheet

piles are pressed alternately by the pressing cylinders.

Moreover, the weight of the basic machine as well as the

skin friction of the idle sheet piles are used as resisting

force for the pressing process.

With the help of process data recording (PDE) all work-

related process data can be displayed and recorded in

the cabin.

The pressing process is controlled either manually or

automatically.

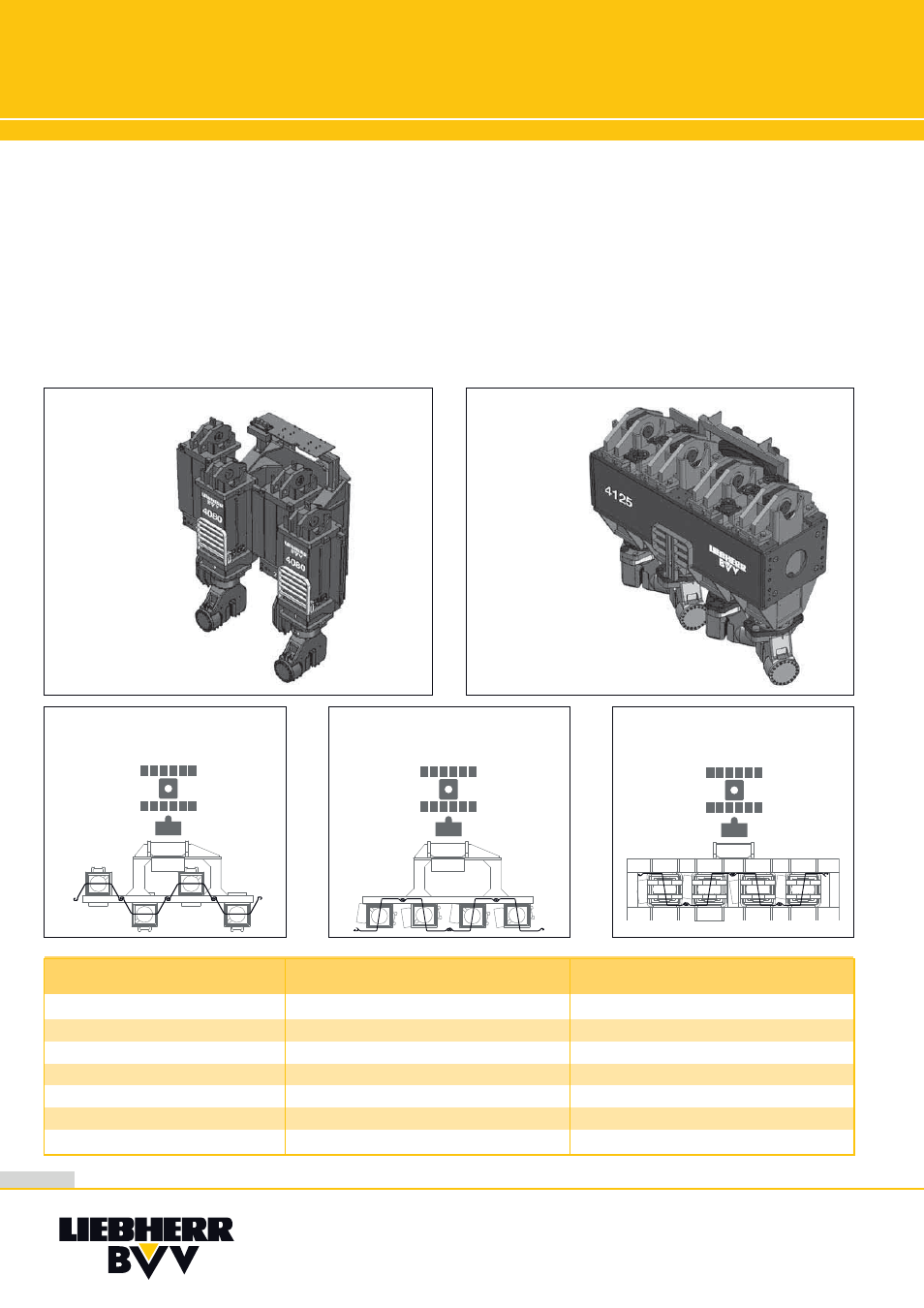

Press 4080

(4x80t)

Press 4125

(4x125 t)

Press layout 4080

with U Profiles

Press layout 4125

with Z Profiles

Press layout 4080

with Z Profiles

Specifications

Sheet pile press 4080

Sheet pile press 4125

Push force

4 x 800 kN

4 x 1250 kN

Pull force

4 x 700 kN

4 x 1000 kN

Stroke of cylinders

400 mm

400 mm

Width of steel sheet pile

500 - 630 mm

630 - 670 mm

Height of steel sheet pile U-form

370 - 452 mm

on request

Working pressure

max. 350 bar

max. 350 bar

Weight approx.

7000 kg

9500 kg