Electrohydraulic actuators (eha), An intelligent solution for rail transport – Liebherr Downloads User Manual

Page 6

6

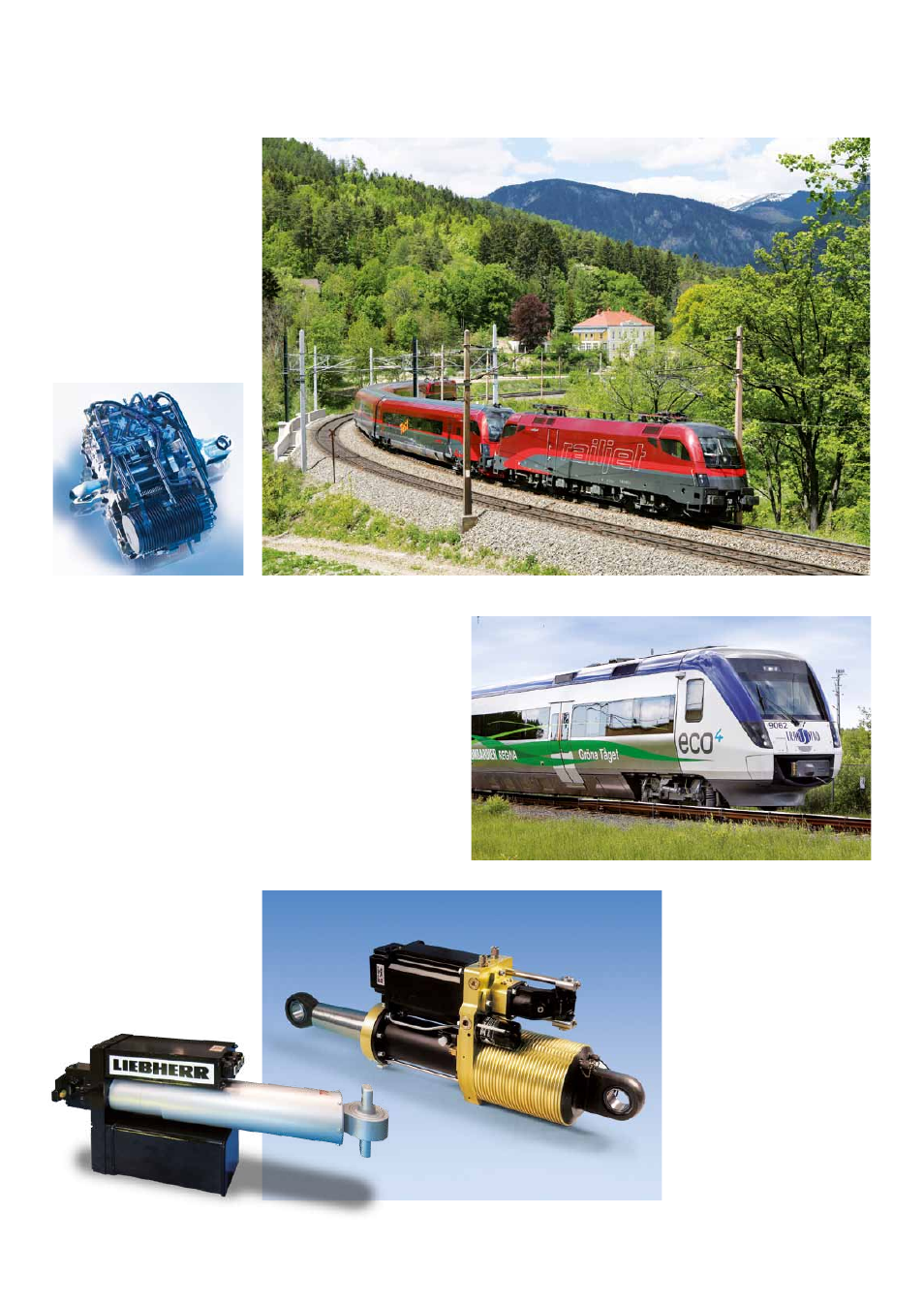

Liebherr actuator for tilting technology

Know-how from the aviation industry: electro-

hydraulic actuator from Liebherr for the Airbus A380

Yaw dampers prolong the service life of bogies

and reduce considerably maintenance costs

Electrohydraulic Actuators (EHA)

an Intelligent Solution for Rail Transport

Electrohydraulic actuators work as

compact, high-performance “power

houses” in rail vehicles and are pro-

duced by Liebherr to meet specific

customer requirements in a wide range

of applications.

These applications include active

lateral suspension and active lateral

centering systems, car positioning sys-

tems, active radial control, active wheel-

set control and tilt technology. Among

other attributes, EHA make a valuable

contribution to reducing the burden on

the environment and preventing wear

while increasing performance.

At train speeds of up to 350 km/h

EHA have to move heavy loads of sev-

eral tons into the position specified by

intelligent control units, or counteract

vibrations occurring on the vehicle.

They not only make faster train speeds

possible but also increase passenger

comfort.

A further key advantage of electro-

hydraulic actuators is that they reduce

car and infrastructure wear enormous-

ly. Initially rather high investment costs

are recouped very quickly through

lower maintenance expenses, reduced

total energy costs and higher carrying

capacity compared with conventional

hydraulic systems.

EHA are self-contained hydraulic

systems. Liebherr performs their as-

sembly, filling and final testing under

extremely clean conditions and thus

ensures they will achieve many years

of service in the tough environment of

rail transport. The car manufacturer fits

the Liebherr EHA to the vehicle and in-

stalls the cable connection for the en-

ergy supply and control systems. The

time-consuming installation work re-

quired on conventional hydraulic sys-

tems to route the lines and fill and vent

the circuit is thus eliminated. This also

removes the risk of contaminating the

hydraulic fluid through incorrect instal-

lation work and, as a result, damaging

the actuator. The system could almost

be described as having ‘plug and play’

functionality.

Electrohydraulic actuators from

Liebherr are fundamentally mainte-

nance-free. If a fault should occur,

however, the entire unit can be quickly

replaced without any hydraulic exper-

tise, thus avoiding prolonged vehicle

downtime.

A controller developed by Liebherr

regulates these innovative systems. Ac-

cording to requirements, the software

can be programmed up to safety level

Sil2 in accordance with EN 50128.

Active lateral suspension is the future, not only on Swedish trains

Railjet Siemens RH 1116