Ix system piping – Burnham FCM120 User Manual

Page 33

33

IX System Piping

A. General System Piping Precautions

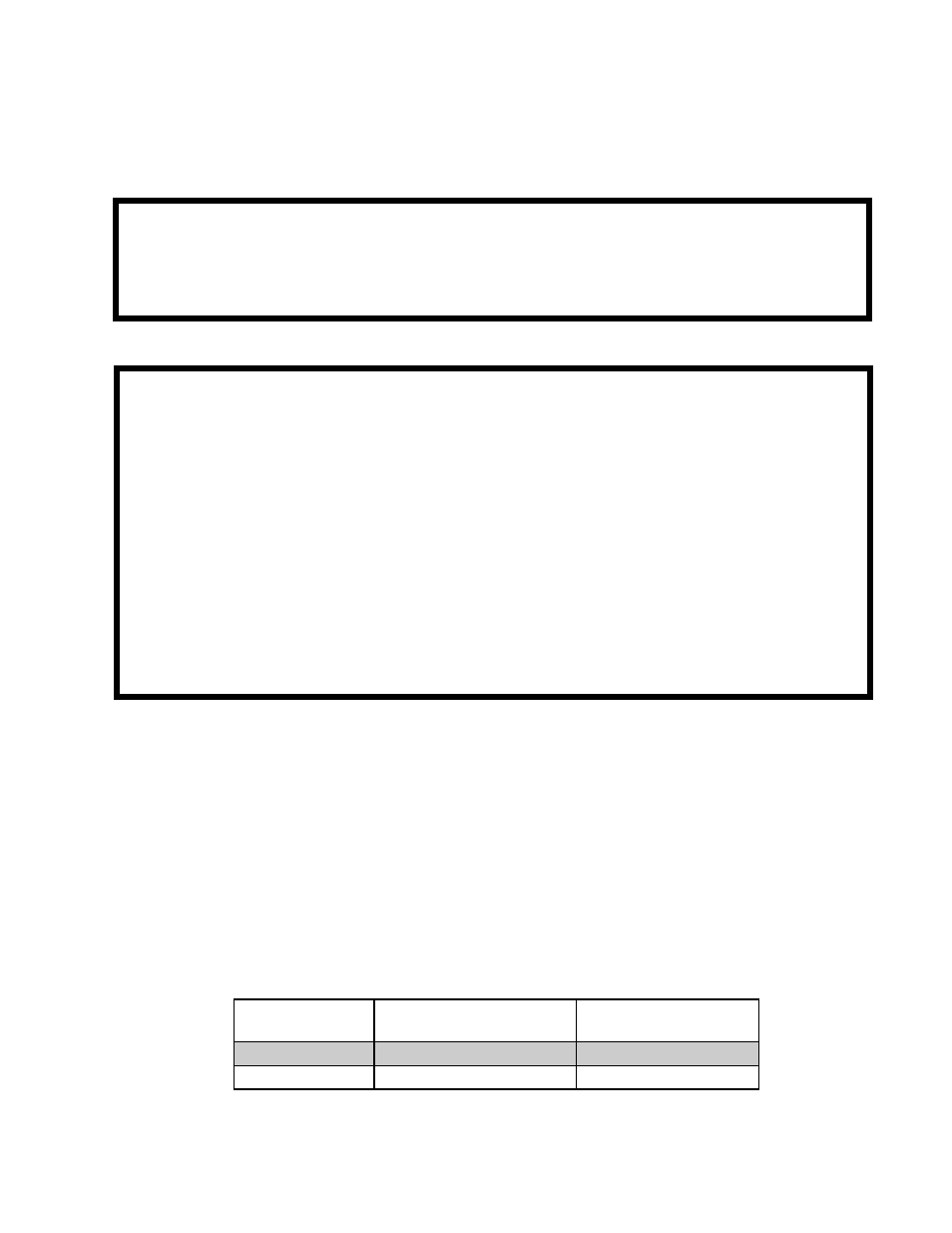

WARNING

INSTALL BOILER SO THAT THE GAS IGNITION SYSTEM COMPONENTS ARE PROTECTED

FROM WATER (DRIPPING, SPRAYING, RAIN, ETC) DURING APPLIANCE OPERATION AND

SERVICE (CIRCULATOR REPLACEMENT, ETC).

CAUTION

THE HEAT EXCHANGER USED IN THE FCM IS MADE FROM A SPECIAL ALUMINUM ALLOY.

FAILURE TO TAKE THE FOLLOWING PRECAUTIONS COULD RESULT IN SEVERE BOILER

DAMAGE.

• BEFORE CONNECTING BOILER, MAKE SURE THAT THE SYSTEM IS FREE OF SEDI-

MENT, FLUX AND ANY RESIDUAL BOILER WATER ADDITIVES. FLUSH THE SYSTEM IF

NECESSARY TO ENSURE THAT THESE CONTAMINATES ARE REMOVED.

• DO NOT CONNECT THIS BOILER TO A SYSTEM THAT IS SUBJECT TO REGULAR ADDI-

TIONS OF MAKEUP WATER OR ONE WHICH EMPLOYS RADIANT TUBING WITHOUT AN

OXYGEN

BARRIER.

• DO NOT ADD ANTIFREEZE OR OTHER BOILER WATER TREATMENT CHEMICALS

EXCEPT THOSE LISTED IN PART XI OF THIS MANUAL.

• MAINTAIN THE PRESSURE IN THE BOILER AT A MINIMUM OF 12 PSI.

• DESIGN SYSTEM TO ENSURE THAT THE FLOW FALLS WITHIN THE LIMITS CALLED

FOR IN TABLE 9.1.

B. System Design

Proper operation of the FCM boiler requires that the water fl ow through the boiler remain within the limits shown in Table

9.1 any time the burner is fi ring. Failure to maintain the fl ow within these limits could result in erratic operation or premature

boiler failure.

There are two basic methods that can be used to pipe the FCM boiler. Method #1 is almost always preferred. The

instructions on the following pages describe these methods for piping FCM boilers and explain how to size the circulator and

piping. Additional information on hydronic system design may be found in Installation of Residential Hydronic Systems (Pub.

#200) published by the Hydronics Institute in Berkeley Heights, NJ.

TABLE 9.1: FLOW REQUIREMENTS THROUGH BOILER

BOILER MODEL

MIN. REQUIRED FLOW

(GPM)

MAX. ALLOWABLE

FLOW (GPM)

FCM090

4.0

9.0

FCM120

4.5

12.0