Lower threading, Caution – Brother ES 2000 User Manual

Page 16

KNOWING YOUR SEWING MACHINE ——————————————————————————————————————————————

14

Memo

● When the sewing machine is started or the

handwheel is turned after winding the

thread around the bobbin, the machine will

make a clicking sound; this is not a

malfunction.

● The needle bar does not move when you

slide the bobbin winding shaft to the right.

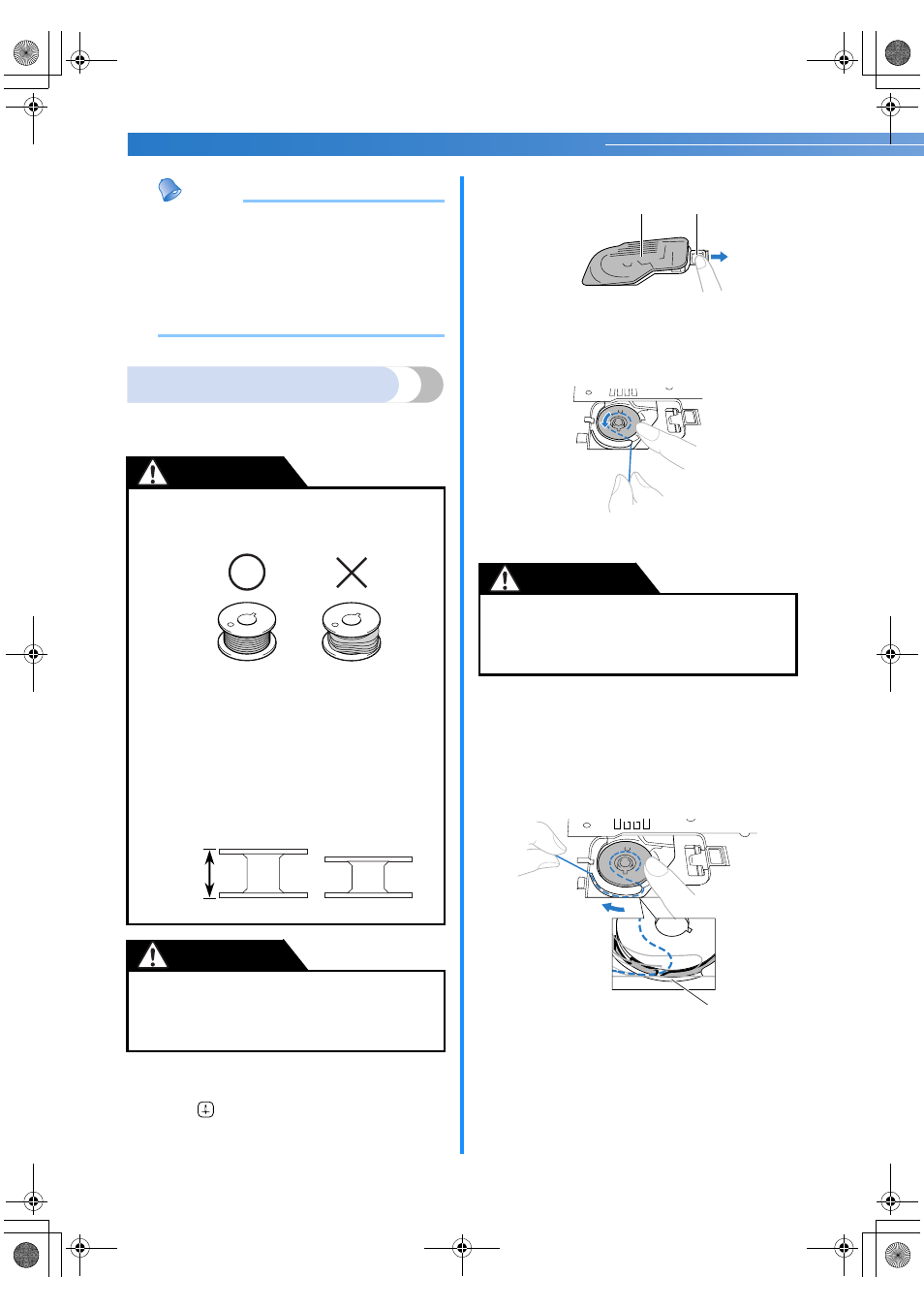

Lower threading

Install the bobbin wound with thread.

• For more details on quick-set bobbin, see page 15.

a

Raise the needle to its highest position by turning

the handwheel toward you (counterclockwise) or

press

(needle

position

button) (for models

equipped with the needle position button), and

raise the presser foot lever.

b

Slide the button and open the cover.

a Cover

b Slide button

c

Put the bobbin in so the thread comes out in

the direction shown by the arrow.

• Only use bobbins that were designed to be

used with this machine.

d

Hold the end of the thread, push the bobbin

down with your finger, and then pass the

thread through the slit, as shown.

• Make sure that the thread is correctly

inserted through the tension-adjusting spring

of the bobbin case. If it is not inserted, re-

insert the thread.

a Tension-adjusting spring

e

Replace the bobbin cover. Put the left tab in

place (see arrow a), and then press lightly on

● Winding the bobbin improperly may cause

the thread tension to loosen, breaking the

needle and resulting in injury.

a Wound evenly

b Wound poorly

● The bobbin was designed specifically for this

sewing machine. If bobbins from other

models are used, the machine will not operate

correctly. Use only the enclosed bobbin or

bobbins of the same type (part code: SA156,

SFB: XA5539-151).

● Make sure you turn the power off while

threading the machine. If you accidentally

step on the foot controller and the machine

starts to sew, you could be injured.

CAUTION

1

2

Actual size

This model

Other models

11.5 mm

(7/16 inch)

CAUTION

● Make sure you set the bobbin so the thread

unrolls in the right direction. If the thread unrolls

in the wrong direction, it may cause the thread

tension to be incorrect or break the needle.

1

2

CAUTION

1

NCBC2000.book Page 14 Thursday, October 21, 2004 4:32 PM