Beckett, Prepare burner & site – Beckett 100 User Manual

Page 4

Instruction Manual –

Model AFII Oil Burner

Beckett

Inspect/prepare installation site

Inspect/prepare installation site

(continued)

Exhaust fans and other air-using devices

Chimney or vent

• Inspect the chimney or vent, making sure it is properly sized and in good

condition for use.

Size air openings large enough to allow for all air-using devices in addition

to the minimum area required for combustion air. If there is any possibility

of the equipment room developing negative pressure (because of exhaust

fans or clothes dryers, for example), pipe combustion air directly to the

burner.

• For those installations not requiring a chimney, such as through-the-wall

vented appliances, follow the instructions given by the appliance and

power venter (if used) manufacturers.

Direct air supply and sidewall venting

Clearances to burner and appliance

• When sidewall venting appliances, carefully follow appliance and power

venter instructions for installation and wiring.

• Provide space around burner and appliance for easy service and

maintenance.

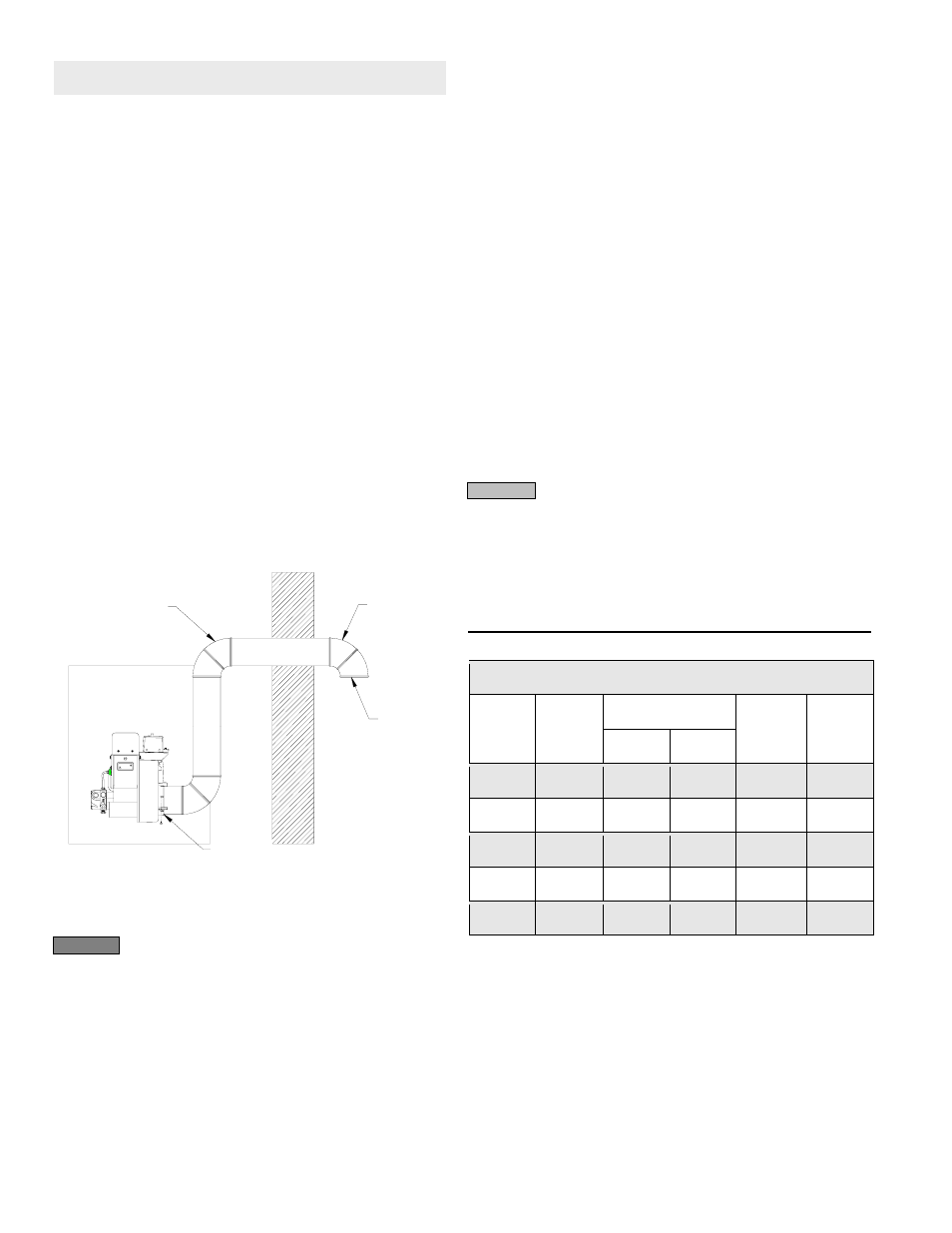

• AFII burners are equipped with a removable air inlet to allow use of a 4”

duct to supply outside air for combustion. Do not exceed 70 equivalent

feet. Allow 6 feet for each elbow.

• Check minimum clearances against those shown by the appliance

manufacturer and by applicable building codes.

1. Remove the inlet cover.

2. Insert 4" duct into the inlet ring.

3. Fasten duct into place using at least 3 sheet metal screws evenly

spaced around the inlet ring. Refer to Figure 1.

Combustion chamber — Burner retrofitting

4. Remove the barometric draft control unless it is in the same

atmospheric pressure zone as the inlet.

On the outside of the home use a 90° elbow pointed downward with a 1/4"

mesh screen over its opening. The air inlet elbow must be located above

the snow line and in such a way as to prevent leaves and/or other debris

from blocking the air flow. Such debris will prevent proper operation of the

burner. Refer to local codes for proper location of inlet.

Figure 1 – Outside air connection

Verify that the appliance combustion chamber provides at least the minimum

dimensions given in Table 2.

When retrofitting an appliance that has an unlined stainless

steel combustion chamber, chamber burnout could result from the use of a

high performance burner. Protect the chamber from high temperatures

through the use of "wet-pac" or a similar ceramic liner. Some equipment may

utilize a stainless steel combustion chamber that has been designed and

tested by the manufacturer for use with a flame retention burner, therefore

ceramic protection would not be necessary. Refer to appliance manufacturer’s

instructions. Failure to comply could result in damage to heating equipment.

Table 2 – Minimum combustion chamber dimensions

Combustion air supply

See NFPA Standard 31 for complete details.

If the burner is not supplied with a reliable combustion air

source, the burner cannot properly burn the fuel. This would result in

incomplete combustion, causing sooting and possible emission of carbon

monoxide. Severe personal injury, death or substantial property damage could

occur.

Chamber dimension (inches)

Rectangular

Firing

rate

(gph)

Round

I.D.

Width Length

Height

Floor to

nozzle

0.50

8

7

8

12

5-6

0.75

9 8 9 12 5-6

1.00

10

9

10

12 ½

5-6

1.25

11

10

11

12 ½

5-6

1.50

12

11

12

13

6-7

INLET

RING

4 IN. DUCT

¼” MESH

SCREEN

AIR

INLET

ELBOW

SK8810

CAUTION

WARNING

Prepare burner & site

Appliance located in confined space

The confined space should have two (2) permanent openings: one near

the top of the enclosure and one near the bottom of the enclosure. Each

opening shall have a free area of not less than (1) one square inch per

1,000 BTU’s per hour of the total input rating of all appliances within the

enclosure. The openings shall have free access to the building interior,

which should have adequate infiltration from the outside.

4