Assembly tools required assembly time estimate, Extension cords, Operating instructions – Black & Decker BDBS100 User Manual

Page 5

5

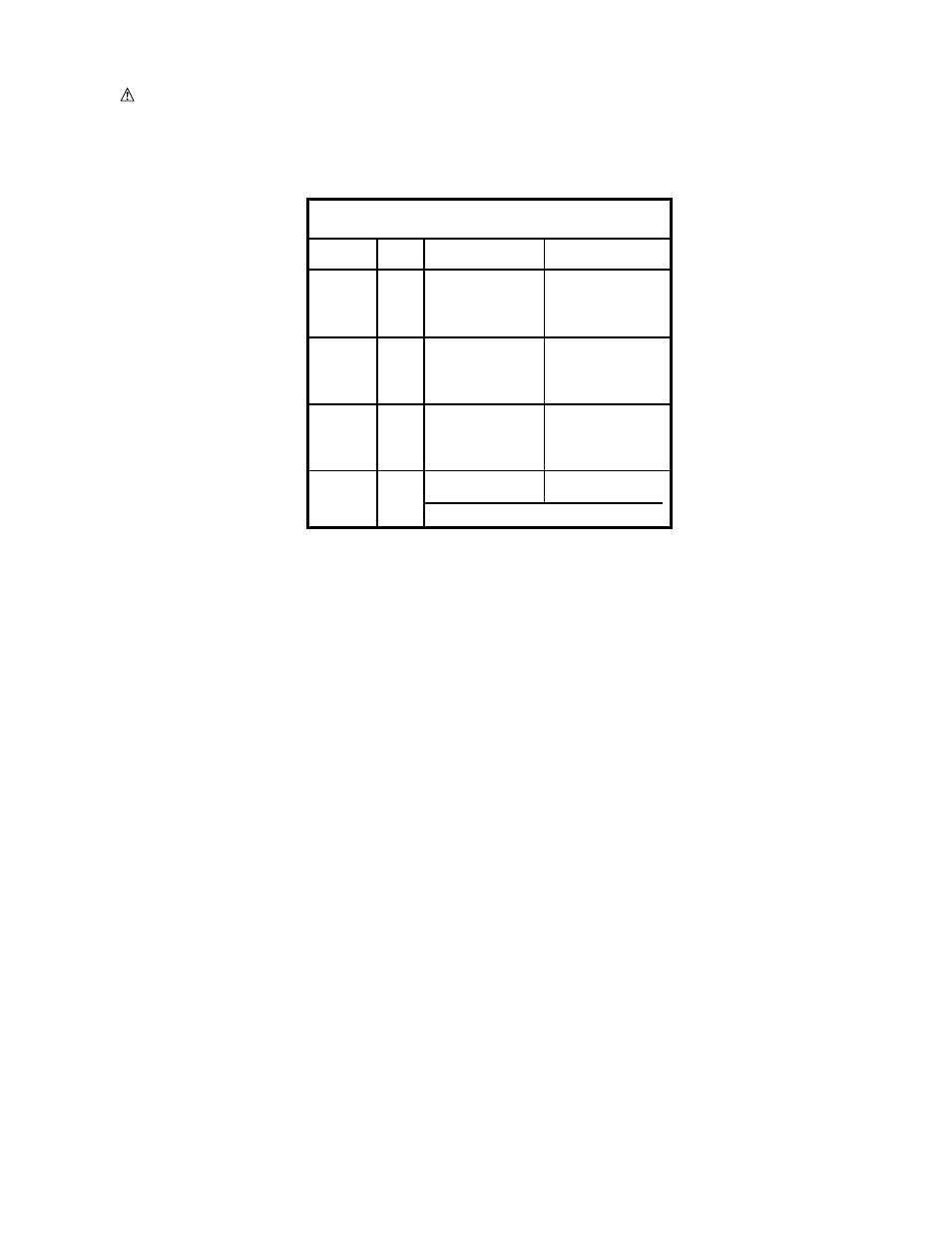

EXTENSION CORDS

WARNING:

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s

plug. When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An

undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig. C, shows the correct

gauge to use depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

OPERATING INSTRUCTIONS

FOREWORD

The BDBS100 is built for precision and performance. The BDBS100 comes with a powerful 3.5 amp motor, rack and

pinion upper blade guide assembly, table tilting assembly, and a flexible lamp.

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from

all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household

floor paste wax.

NOTICE: THE MANUAL COVER PHOTO ILLUSTRATES THE CURRENT

PRODUCTION MODEL. ALL OTHER ILLUSTRATIONS ARE REPRESENTATIVE

ONLY AND MAY NOT DEPICT THE ACTUAL COLOR, LABELING OR

ACCESSORIES AND MAY BE INTENDED TO ILLUSTRATE TECHNIQUE ONLY.

Fig. C

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Total Length

Gauge of

Rating

Volts

of Cord in Feet

Extension Cord

0-6

120

up to 25

18 AWG

0-6

120

25-50

16 AWG

0-6

120

50-100

16 AWG

0-6

120

100-150

14 AWG

6-10

120

up to 25

18 AWG

6-10

120

25-50

16 AWG

6-10

120

50-100

14 AWG

6-10

120

100-150

12 AWG

10-12

120

up to 25

16 AWG

10-12

120

25-50

16 AWG

10-12

120

50-100

14 AWG

10-12

120

100-150

12 AWG

12-16

120

up to 25

14 AWG

12-16

120

25-50

12 AWG

12-16

120

GREATER THAN 50 FEET NOT RECOMMENDED

ASSEMBLY TOOLS REQUIRED

ASSEMBLY TIME ESTIMATE

1.) 3mm hex wrench - supplied

2.) 4mm hex wrench - supplied

3.) flat-head screwdriver

4.) phillips screwdriver

1 hour or less