Bryant 3-PHASE 602A User Manual

Page 20

5. Ensure that setscrew engages the flat area on the motor shaft

when tightening.

6. Replace grille.

V.

ELECTRICAL CONTROLS AND WIRING

Inspect and check the electrical controls and wiring annually. Be

sure to turn off the electrical power to the unit and install lockout

tag.

Remove access panel to locate all the electrical controls and

wiring. Check all electrical connections for tightness. Tighten all

screw connections. If any smoky or burned connections are

noticed, disassemble the connection, clean all the parts, restrip the

wire end and reassemble the connection properly and securely.

After inspecting the electrical controls and wiring, replace all the

panels. Start the unit, and observe at least one complete cooling

cycle to ensure proper operation. If discrepancies are observed in

operating cycle, or if a suspected malfunction has occurred, check

each electrical component with the proper electrical instrumenta-

tion. Refer to the unit wiring label when making these checkouts.

NOTE: Refer to the Sequence of Operation section as an aid in

determining proper control operation.

VI.

REFRIGERANT CIRCUIT

Inspect all refrigerant tubing connections and the unit base for oil

accumulation annually. Detecting oil generally indicates a refrig-

erant leak.

WARNING: System under pressure. Relieve pressure

and recover all refrigerant before system repair or final

unit disposal to avoid serious injury or death. Use all

service ports and open all flow-control devices, including

solenoid valves.

If oil is detected or if low performance is suspected, leak-test all

refrigerant tubing using an electronic leak detector, or liquid-soap

solution. If a refrigerant leak is detected, refer to Check for

Refrigerant Leaks section.

If no refrigerant leaks are found and low performance is suspected,

refer to Checking and Adjusting Refrigerant Charge section.

VII.

INDOOR AIRFLOW

The indoor airflow does not require checking unless improper

performance is suspected. If a problem exists, be sure that all

supply- and return-air grilles are open and free from obstructions,

and that the air filter is clean. When necessary, refer to Indoor

Airflow and Airflow Adjustments section to check the system

airflow.

VIII.

METERING DEVICE

Refrigerant metering devices are fixed orifices and are located in

the inlet header to the indoor and outdoor coils.

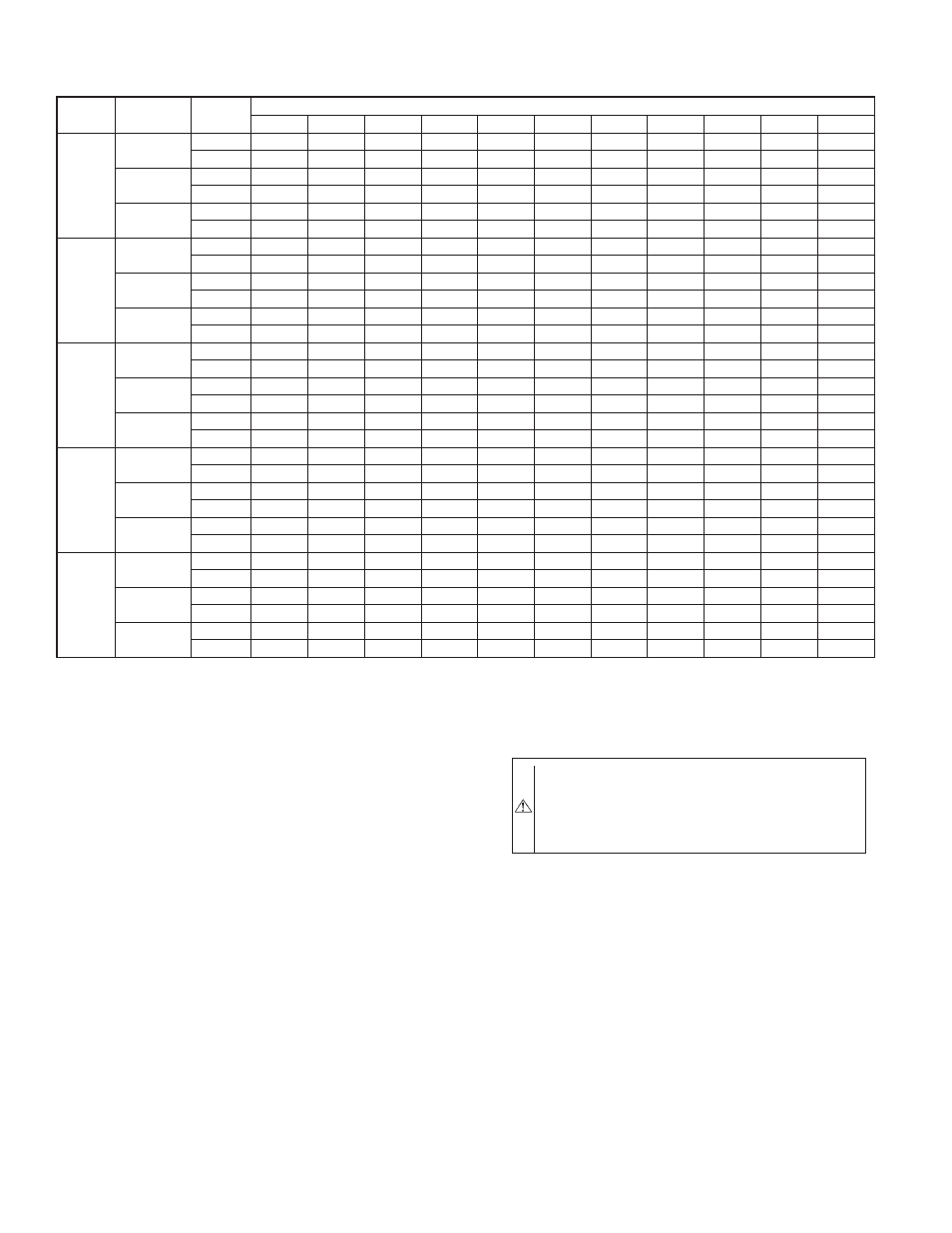

TABLE 8—WET COIL AIR DELIVERY

UNIT 602A 030-060 (DEDUCT 10 PERCENT FOR 208-V)*

UNIT

MOTOR

SPEED

EXTERNAL STATIC PRESSURE (IN. WG)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

30

Low

Watts

276

276

272

-

-

-

-

-

-

-

-

Cfm

963

929

781

-

-

-

-

-

-

-

-

Med

Watts

375

377

371

362

354

350

-

-

-

-

-

Cfm

1202

1170

1079

976

884

807

-

-

-

-

-

High

Watts

-

-

-

-

469

449

435

428

-

-

-

Cfm

-

-

-

-

1174

988

828

718

-

-

-

36

Low

Watts

462

451

431

411

394

381

-

-

-

-

-

Cfm

1374

1290

1205

1116

1020

916

-

-

-

-

-

Med

Watts

523

506

490

471

449

426

-

-

-

-

-

Cfm

1500

1408

1301

1190

1082

977

-

-

-

-

-

High

Watts

-

645

628

610

595

584

575

-

-

-

-

Cfm

-

1474

1369

1267

1169

1069

962

-

-

-

-

42

Low

Watts

620

600

586

574

562

548

530

510

487

462

439

Cfm

1662

1621

1581

1540

1496

1447

1392

1331

1263

1186

1103

Med

Watts

-

-

-

-

686

661

634

606

577

547

517

Cfm

-

-

-

-

1722

1662

1594

1515

1427

1330

1227

High

Watts

-

-

-

-

-

-

-

757

730

704

682

Cfm

-

-

-

-

-

-

-

1669

1577

1486

1402

48

Low

Watts

620

600

586

574

562

548

530

-

487

-

-

Cfm

1662

1621

1581

1540

1496

1447

1392

1331

1263

-

-

Med

Watts

763

747

729

709

686

661

634

606

577

547

517

Cfm

1917

1868

1822

1774

1722

1662

1594

1515

1427

1330

1227

High

Watts

-

-

-

852

832

809

784

757

730

704

682

Cfm

-

-

-

1982

1914

1839

1757

1669

1577

1486

1402

60

Low

Watts

597

592

578

526

460

452

445

-

-

-

-

Cfm

2265

2190

2101

2033

1974

1869

1614

-

-

-

-

Med

Watts

754

730

707

687

671

658

646

630

603

558

486

Cfm

2383

2282

2202

2134

2070

2005

1935

1858

1771

1667

1576

High

Watts

901

876

856

836

813

785

755

723

696

681

687

Cfm

2480

2383

2301

2233

2175

2122

2066

1998

1910

1788

1619

* Air delivery values are based on operating voltage of 230-v or 460-v, wet coil, without filter or electric heater. Deduct filter and electric heater pressure drops to obtain static

pressure available for ducting.

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of rated cooling capacity. Evaporator coil frosting may occur at airflows below

this point.

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

3. Deduct 10 percent for 208-v.

—20—