Spa mc 2300, 16 maintenance and lubrication – Briggs & Stratton MC 2300 User Manual

Page 8

SpA MC

2300

8

IMPORTANT :

Before doing the operations described below, switch off the engine.

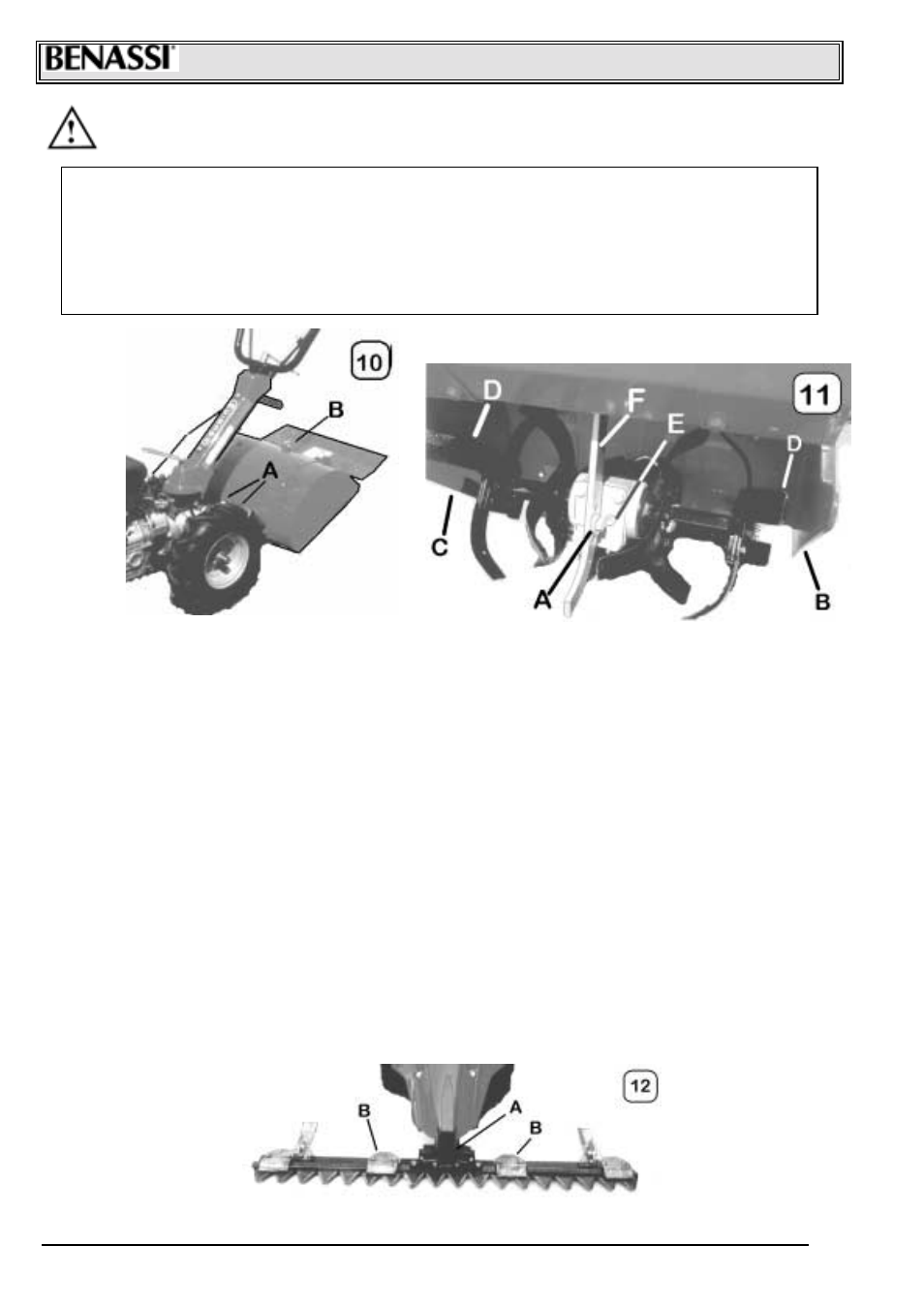

The mill ing unit (Pi cture 11) can b e mounted so that the mo wing rotation corr esponds to the advan cing wh eel rotation or

contrar y to it. See the dart indication on the mo wing unit side.

To change the rotation take out the hood panel for milling cutter unscrewing the two bolts (Ref. “A” Pi cture 10) and the bolt

(Ref. B Picture10).

Slip the milling transmi ssion unit off by pulling the lever (Ref. B Picture 8), remove the spur (Ref. A Picture 11), taking off the

bolt (Ref. A Picture 11) and mount it again upside-down. Then mount the hood panel for milling cutter again on the

transmission unit upsid e-down making al l the inver se pro cess .

The milling cutter hood panel can en able, through two adj ustable sid es (Ref. “B” and “C” Picture 11) two wor king width, cm.

40 and 50.

In the narro wer version, the mi lling bl ades of the external cutters have to be scr ewed and turned in wards (Ref. ”D” Pi cture11).

16 MAINTENANCE AND LUBRICATION

A good mai ntenance and a perf ect lubricati on are both necess ary operations t o keep your mac hine perfectl y ef ficient . The machine is

normally deli vered pac ked and without engine oil, as it is indicated on t he note applied to the engine.

ENGINE

Please follow the specific “ENGINE USE AND MAINTENANCE” bookl et provided with the mac hine for i nstructions, use and mai ntenance of

the engine.

It is a good rule t o control the oil level ever y 5 hours of work and to change it every 50 hours. Use oil SAE 40 in summer and SAE 20 in

wint er. The first oil c hange must be done aft er 10 hours of wor k.

Control t hat the air-filter is clean, if t he filter is in oil bat h control t he level ever y 8-10 hours of wor k or even more frequentl y if you are

wor king in dust y grounds . Use engine oil t o rest ore t he oil level; before r efilling the oil tank, was h it c aref ully.

GEAR BOX

Control t he oil level ever y 50 hours of work by t aking out t he cap on the gear box c ase (t he machine must be in t he horizontal position).

If necess ary, add oil SAE 80-90. It is suggested t o c hange oil at least onc e a year . T o empt y t he oil in the gear box, unscrew t he cap of t he

inferior part of t he box (Ref. “A” Picture 14), take out t he oil cap (Ref. “A” picture 7) to allow the oil flowing out more easily. Put t he inf erior

cap again and fill with oil t hough the cap (Ref . ”A” Pict ure 7) up to t he screw level (Ref . “B” Pict ure 7).

MILLING CUTTER

Befor e starti ng to wor k, c ontrol that all screws are well fast ened, especiall y t hose of the mill hoes .

Control t he oil level of t he milling cutter trans mission unit ever y 100 hours of work , by taking out the c ap on t he lid (Ref. “E” Pict ure 11). Oil

must fill almost c omplet ely the gearbox c ase. Us e SAE 80- 90 oil.

CUTTERBAR

! Befor e starti ng to wor k, c ontrol that all screws are tight fas tened.

! Every 4 hours of work lubricate the i nside of the blade head.

! Every 10 hours of wor k lubricate the ecc entric ferrule - (Ref. “A” Picture 12).

! Every 20 hours of wor k lubricate the linkage between the c utterbar and the machi ne.

! Periodicall y is needed to control bl adehol ders (Ref. “B” Picture 12) s o that the blade has not too much freeplay or is fastened too tight. If

the c utting of t he grass aft er the adjust ments is not s atisf ying, t he blade needs to be grinded or changed.