Troubleshooting guide – Bakers Pride COUNTERTOP VH1828G User Manual

Page 18

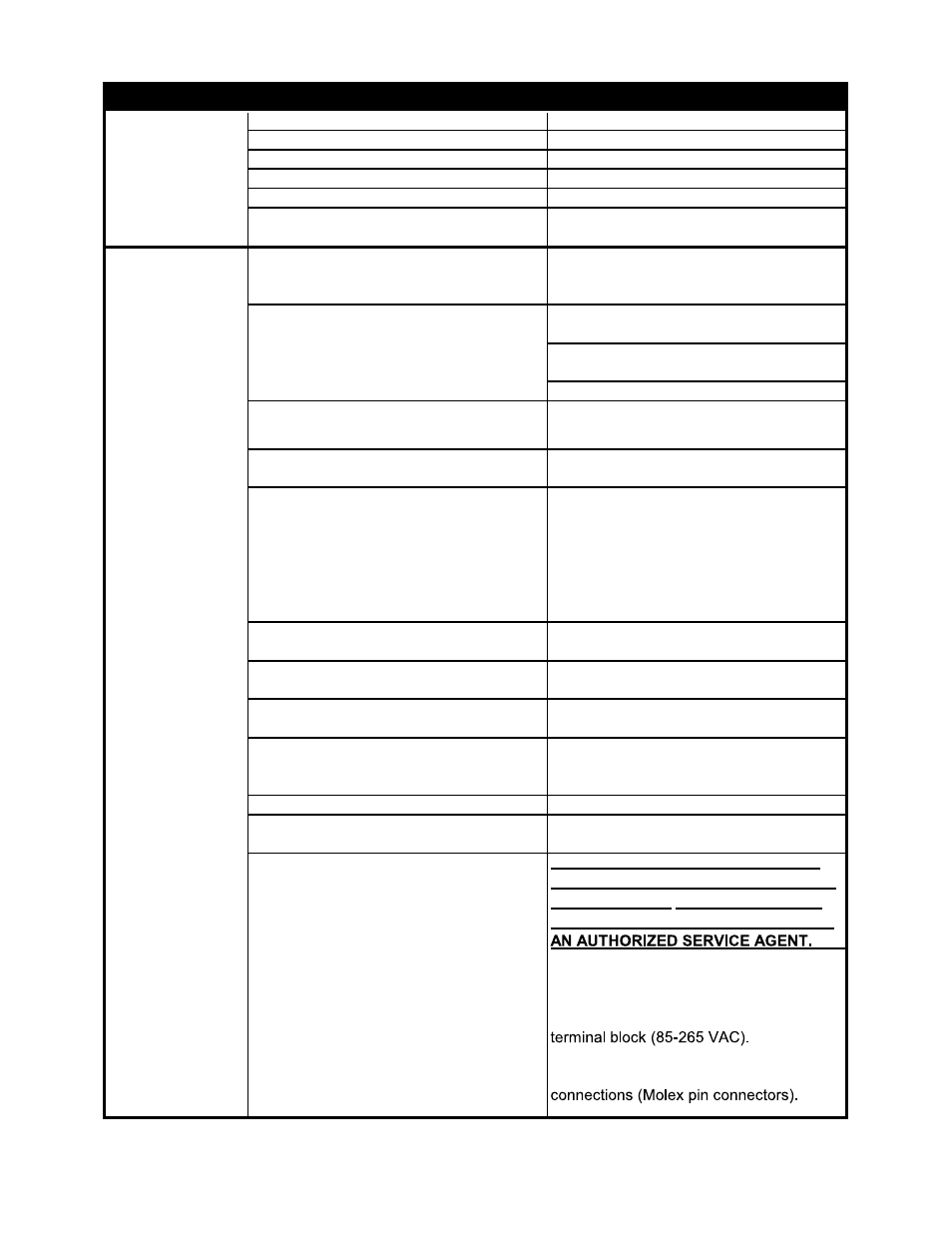

19. TROUBLESHOOTING GUIDE

THE PROBLEM

THE CAUSE

THE SOLUTION

Belt master link(s) missing, broken, or

installed incorrectly.

Oven doesn't start

Conveyor belt

doesn't move, or it

moves unevenly.

Unexpected speed

changes.

Drive sprockets worn out, missing, or mis-

aligned

Belt loose. Drive sprockets not engaging

belt links.

Drive coupling loose

Speed setting very high (long cook time)

Drive coupling missing

Conveyor gearmotor failed

Locate and re-install or replace

Replace sprockets or entire drive shaft

assembly. Tighten sprockets to shaft.

CAUTION: THE FOLLOWING TESTS

ARE PERFORMED WITH LIVE POWER

WITH CONTROL BOX OPEN. THESE

TESTS TO BE PERFORMED ONLY BY

1. Test by disconnecting conveyor belt. If

no shaft rotation or motor noise when

power applied, test power supply.

2. Test power supply input connections @

3. Remove cover from power supply

enclosure and verify integrity of internal

Drive shaft pin missing

Conveyor belt jammed

Check power distribution terminal block

below Power Control Box

If belt still too loose, remove one belt link.

Tighten conveyor belt using adjustable

tensioner at one end of belt frame.

Properly re-attach and tighten to

gearmotor output shaft

Remove belt assembly to identify

obstruction to belt movement. Remedy

problem. Straighten bent belt links

Tighten setscrew to gearmotor output

shaft (shaft is "flatted" for setscrew grip)

Align and engage shaft pin to slot in drive

coupling

Install master link(s) properly

Turn ON

Plug cord in

CAUTION: TURN OFF POWER, open

Power Control Box, and flip Reversing

Switch to opposite position.

Adjust speed to FAST to verify if knob is

tight and potentiometer working correctly

Verify that all sprockets are tight and

properly aligned with belt "segments".

Tighten setscrew in knob on pot shaft.

NOTE: Mark on knob should line up with

mark on label to indicate cook time in

minutes. This may require calibration of

belt movement using timing marks on

conveyor frame. For CALIBRATION, see

Section 18.

Conveyor drive shaft not engaged to

coupling

Main circuit breaker OFF

Power cord disconnected

Power connections broken

Conveyor belt running backwards

Speed knob loose

Blown fuse

Main Switch broken

Replace fuse with identical type - 10 amp

Replace

Main Switch OFF

Turn ON

18