Bryant 591B User Manual

Page 5

C.

REFRIGERANT TUBING

Connect vapor tube to fitting on outdoor unit vapor service valves.

Connect liquid tube to filter drier. (See Fig. 6 and Table 1.) Use

refrigerant grade tubing.

D.

SWEAT CONNECTION

CAUTION:

To avoid valve damage while brazing, ser-

vice valves must be wrapped in a heat-sinking material

such as a wet cloth.

Use refrigerant grade tubing. Service valves are closed from

factory and ready for brazing. After wrapping service valve with a

wet cloth, braze sweat connections using industry accepted meth-

ods and materials. Consult local code requirements. Refrigerant

tubing and indoor coil are now ready for leak testing. This check

should include all field and factory joints.

E.

EVACUATE REFRIGERANT TUBING AND INDOOR

COIL

CAUTION:

To avoid compressor damage, never use

the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed. Always break a vacuum with dry nitrogen.

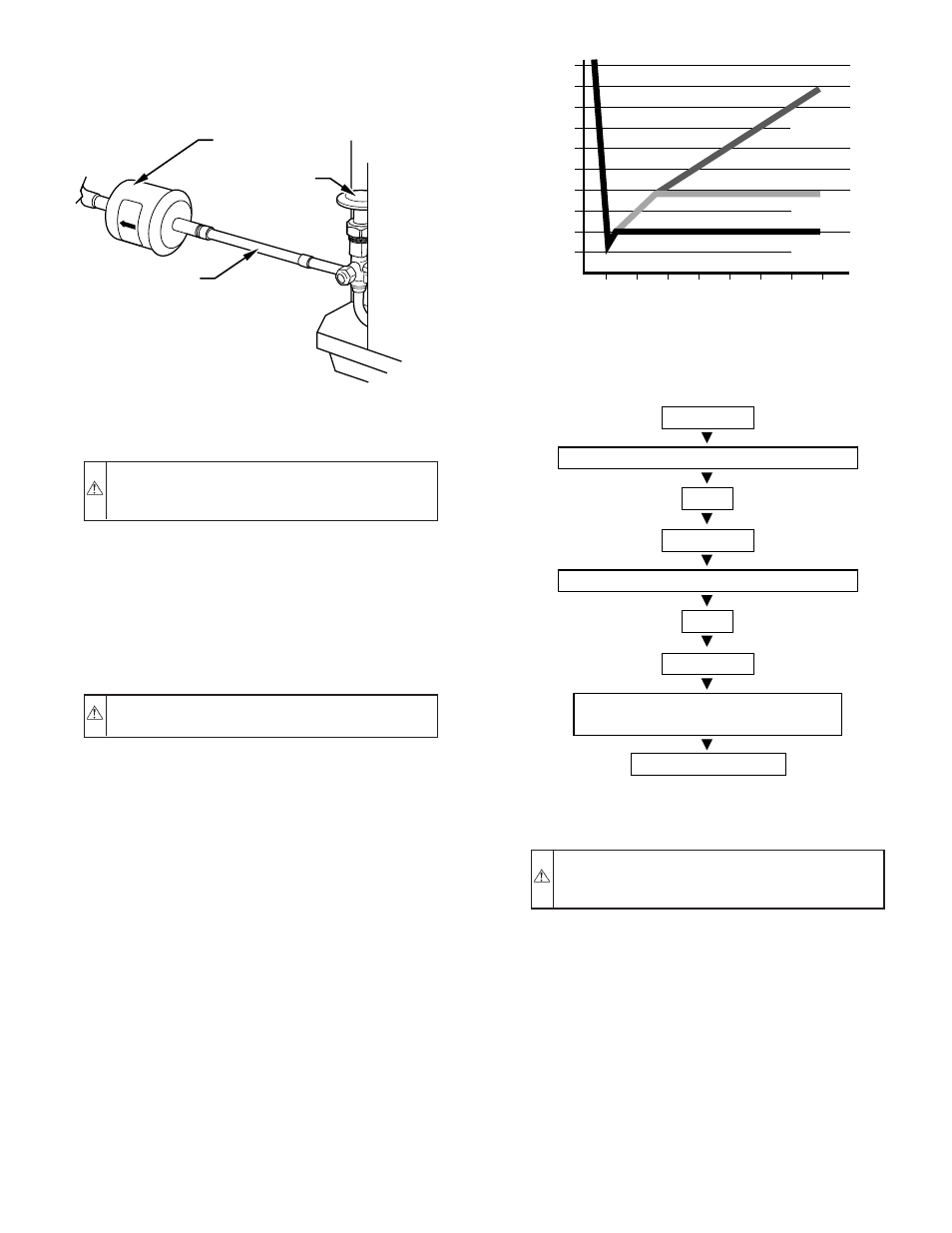

DEEP VACUUM METHOD

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum

method is the most positive way of assuring a system is free of air

and liquid water. (See Fig. 7.)

TRIPLE EVACUATION METHOD

The triple evacuation method should only be used when vacuum

pump is only capable of pumping down to 28 in. of mercury

vacuum and system does not contain any liquid water. Refer to

Fig. 8 and proceed is as follows:

1. Pump system down to 28 in. of mercury and allow pump to

continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a dry nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hr.

During this time, dry nitrogen will be able to diffuse

throughout the system absorbing moisture.

5. Repeat this procedure as indicated in Fig. 8. System will

then be free of any contaminants and water vapor.

VIII.

MAKE ELECTRICAL CONNECTIONS

WARNING:

To avoid personal injury or death, do not

supply power to unit with compressor terminal box cover

removed.

Be sure field wiring complies with local and national fire, safety,

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE:

Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage may fluctuate above or below

permissible limits.

NOTE:

Use copper wire only between disconnect switch and

unit.

NOTE:

Install branch circuit disconnect of adequate size per

NEC to handle unit starting current. Locate disconnect within sight

from and readily accessible from unit, per Section 440-14 of NEC.

Fig. 6—Liquid-Line Filter Drier

A95509

LIQUID-LINE

FILTER-DRIER

CONNECTOR

TUBE

R-410A

LIQUID

SERVICE

VALVE

Fig. 7—Deep Vacuum Graph

A95424

500

MINUTES

0

1

2

3

4

5

6

7

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

A95424

Fig. 8—Triple Evacuation Method

A95425

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHARGE SYSTEM

BREAK VACUUM WITH DRY NITROGEN

EVACUATE

WAIT

—5—