4 maintenance, 5 troubleshooting – Bosch AQ4 GWH 1600 P User Manual

Page 10

10

AQ4 Manual

4 Maintenance

The vent system must be inspected at regular 3-month

intervals. Points of inspection are as follows:

1. Screened opening of the vent hood should be free

from foreign material and cleaned as necessary.

2. Check all vent system connections for leakage

and reseal where needed with high temperature

silicone sealant. If any vent pipe component shows

signs of deterioration, replace immediately.

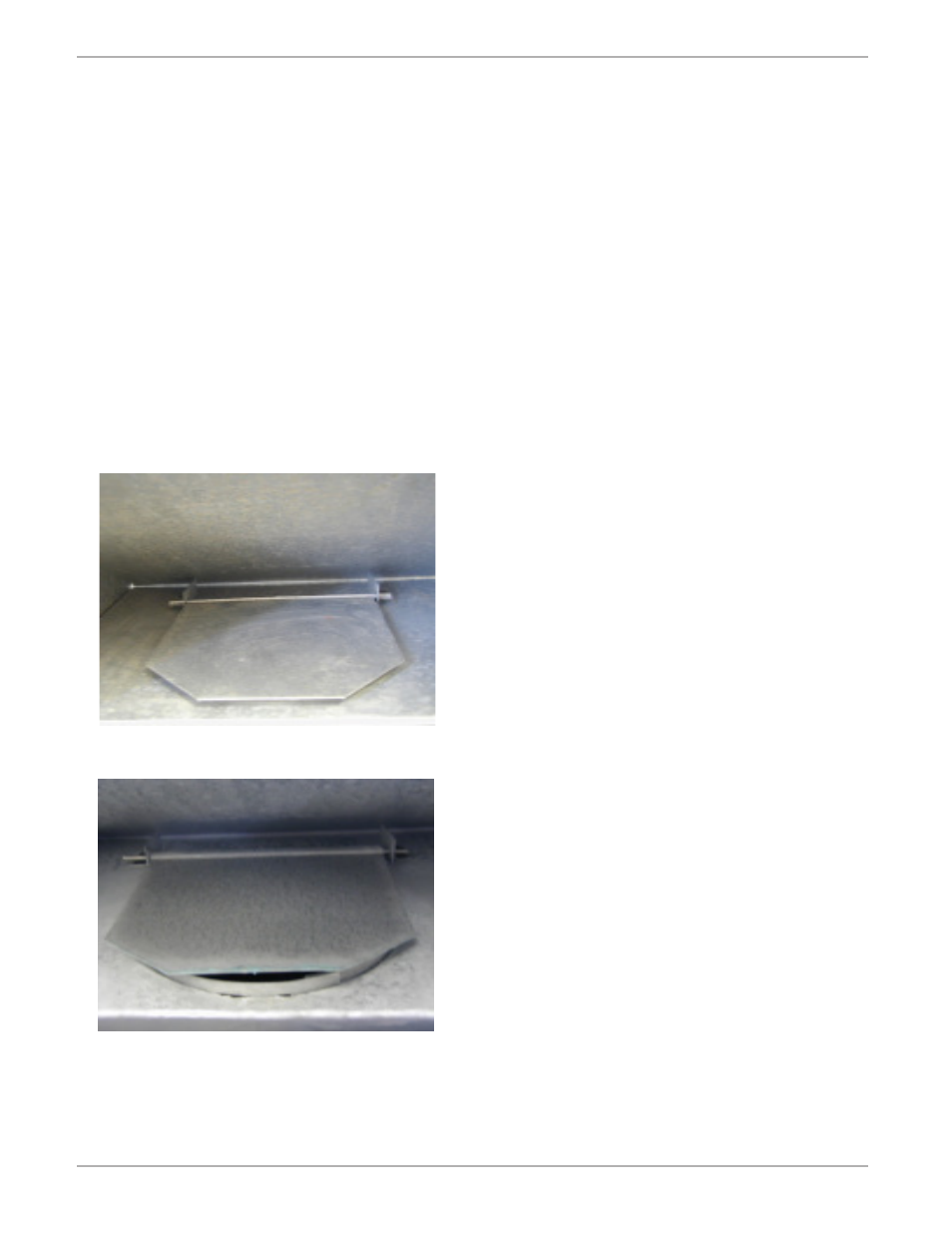

3. Inspect for proper closure of the back draft

flapper. If the flapper does not properly close,

there is a risk of freezing air coming across the

heat exchanger which may cause the pipes inside

to freeze and burst. This condition is not covered

by the water heater warranty. See Fig. 11A for a

properly closed back draft flapper.

4. Conduct safety interlock test and operation of

back draft flapper once a year (Chapter 3.1.3).

Maintenance

Fig. 11B Improperly closed back draft flapper

Fig. 11A Properly closed back draft flapper

5 Troubleshooting

5.1 Introduction

Many of the questions customers ask regarding

operation of this unit can be answered by following

the troubleshooting steps outlined below. Visit

our website at www.boschhotwater.com for more

detailed troubleshooting. For best results, perform

each step before proceeding to the next.

5.2 Power vent motor runs all the time or

intermittently without water flow

1. The power vent motor is flow switch activated.

If the internal paddle inside the flow switch is

jammed, it may constantly send a signal to turn on

the fan. Shut off water supply to heater and drain.

Remove flow switch from water heater piping by

removing clips on both ends. Flush water through

both ends of flow switch to free up internal paddle

and clear debris. After flushing, shake flow switch

up and down. The internal paddle should be heard

moving freely back and forth.

2. Large amounts of water demand can create

pressure drops throughout the plumbing. This

may allow for movement of the power vent flow

switch and activate the fan. Activated sprinkler

systems or flushed toilets are common causes for

this symptom. Consult a plumbing professional

to correct unintentional water flow through the

heater.

3. In buildings with excessively high water pressure,

a condition known as “water hammer” may exist.

This condition is caused by a combination of high

water pressure and the abrupt closing of a faucet

valve or internal washer/toilet valve. This instant

change in flow results in an instant change in the

internal pressures in the pipe, which then sends

a shock wave through the pipe. This physical

shock will shake, rattle or cause a loud bang in the

plumbing which is referred to as “water hammer.”

Such a shock wave may cause movement of the

power vent flow switch which will activate the fan.

Consult a plumbing professional for the use of a

pressure reducing valve, expansion tank or water

hammer arrestor to combat this condition.