Calibration process of kc80 and kip c7800, General, Color calibration/linearization – Konica Minolta KIP Color 80 User Manual

Page 4

Color Calibration/Linearization

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP. 2013 KIP. vii.iv

3

Calibration Process of KC80 and KIP C7800

General

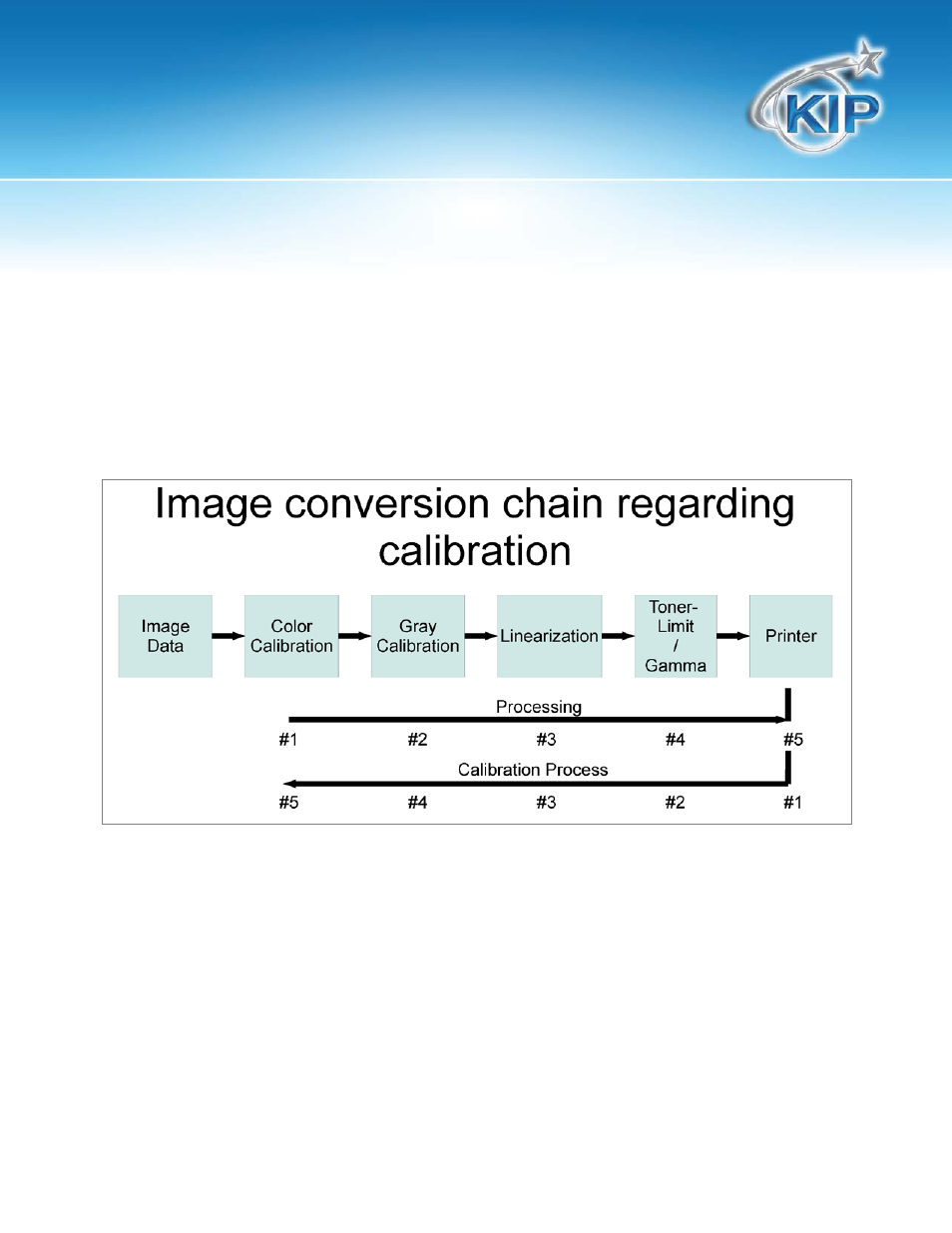

The calibration process is needed to achieve optimal printing results. It consists of several steps. To understand

how the calibration must be performed, the image processing chain is described first:

Image data is converted by 6 modules:

Color calibration module (1): Converting image data into printer color space

Gray calibration (2): Make printed grays (R=G=B) perceptually uncolored

Linearization module (3): Accurate linearization of the printing process

Toner-Limit / Gamma (4): Reduce maximum toner and rough linearization of the printing process

Printer (5): Toner density

The calibration process must be performed in the reverse order and must be performed for each media type

and print mode. Otherwise the calibration will result in unpredictable colors.

The calibration processing steps for one media type and one print mode are explained in detail below.