Vollrath F131YG User Manual

Page 23

17

Off Time (sec)

Increasing this value will increase the time between

freezing cycles in "Standby Mode" and result in an

increase of product temperature in the barrel.

Stb Time (sec)

This setting determines the total amount of time in

"Standby Mode".

Sl1DrvOn (sec)

Adjustments to this setting affect the amount of

time the auger rotates in the stir cycle. This stir

cycle only occurs in "Sleep 1 Mode".

Sl1DrOff (sec)

Adjustments to this setting affect the time between

stir cycles. The stir cycle only occurs in "Sleep 1

Mode".

Sl2CutIn (°F)

Changing this setting affects the temperature at

which the freezing cycle starts in "Sleep 2 Mode".

Sl2CtOut (°F)

Changing this setting affects the temperature at

which the freezing cycle stops in "Sleep 2 Mode".

DftOffTm (sec)

In "Serve Mode", this value determines the

maximum time without a freezing cycle. If this

value is met, a freezing cycle will start. In the event

of a freezing cylinder temperature sensor failure,

this value affects the amount of time between

freezing cycles during "Serve Mode".

Refriger

This setting changes how the control handles the

storage refrigeration cycle. The setting for the

E131 and F131 is 2 Hopper on the left control and

None on the right control.

HprCutIn (°F)

This setting determines the temperature at which

the hopper refrigeration cycle starts. This setting

is only available on the left control.

HprCtOut (°F)

This setting determines the temperature at which

the hopper refrigeration cycle stops. This setting

is only available on the left control..

Hpr Off (min)

If the temperature sensor in the hopper fails, this

setting determines the time between hopper

refrigeration cycles. This setting is only available

on the left control..

Hpr On (sec)

If the temperature sensor in the hopper fails, this

setting determines the length of the hopper

refrigeration cycle. This setting is only available

on the left control..

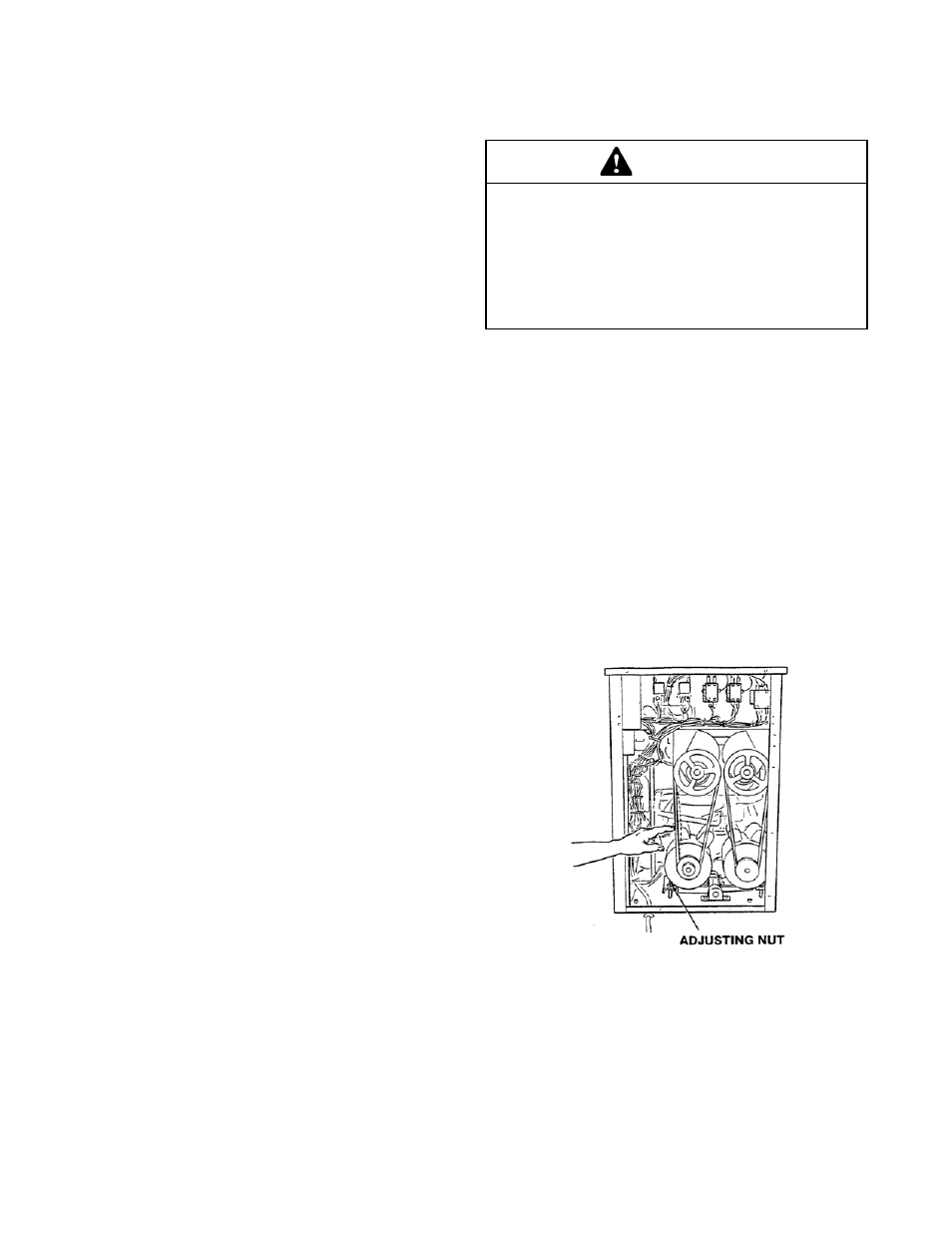

4.8

DRIVE BELT TENSION ADJUSTMENT

To check belt tension, refer to Figure 4-4 and follow the

steps below:

A.

Remove the back panel.

B.

Use a Burroughs Belt Tension Gauge to set the

tension for the drive belt. Set the belt tension to 35-

40 lbs.

C.

If an adjustment is necessary, loosen the four

motor plate retaining nuts, adjust belt tension then

retighten the four nuts.

D.

Using a straightedge, check that the drive motor

pulley is aligned with the speed reducer pulley.

Align the pulley if necessary.

NOTE

Belt life will be increased if new drive belts are tight-

ened after two or three weeks of operation.

4.9

CONDENSER CLEANING

The air-cooled condenser is a copper tube and aluminum fin

type. Condensing is totally dependent upon airflow. A

plugged condenser filter, condenser, or restrictions in the

louvered panel will restrict airflow. This will lower the

capacity of the system and damage the compressor. The

condenser must be kept clean of dirt and grease. The

machine must have a minimum of 3” (7.5 cm) of ventilation

WARNING

Hazardous voltage

The Main Freezer Power switch must be placed in

the OFF position when disassembling for servicing.

The freezer must be disconnected from electrical

supply before removing any access panel. Failure to

disconnect power before servicing could result in

death or serious injury.

Figure 4-4 Belt Tension Adjustment