Pfannenberg DTS 3000 Series User Manual

Page 9

6

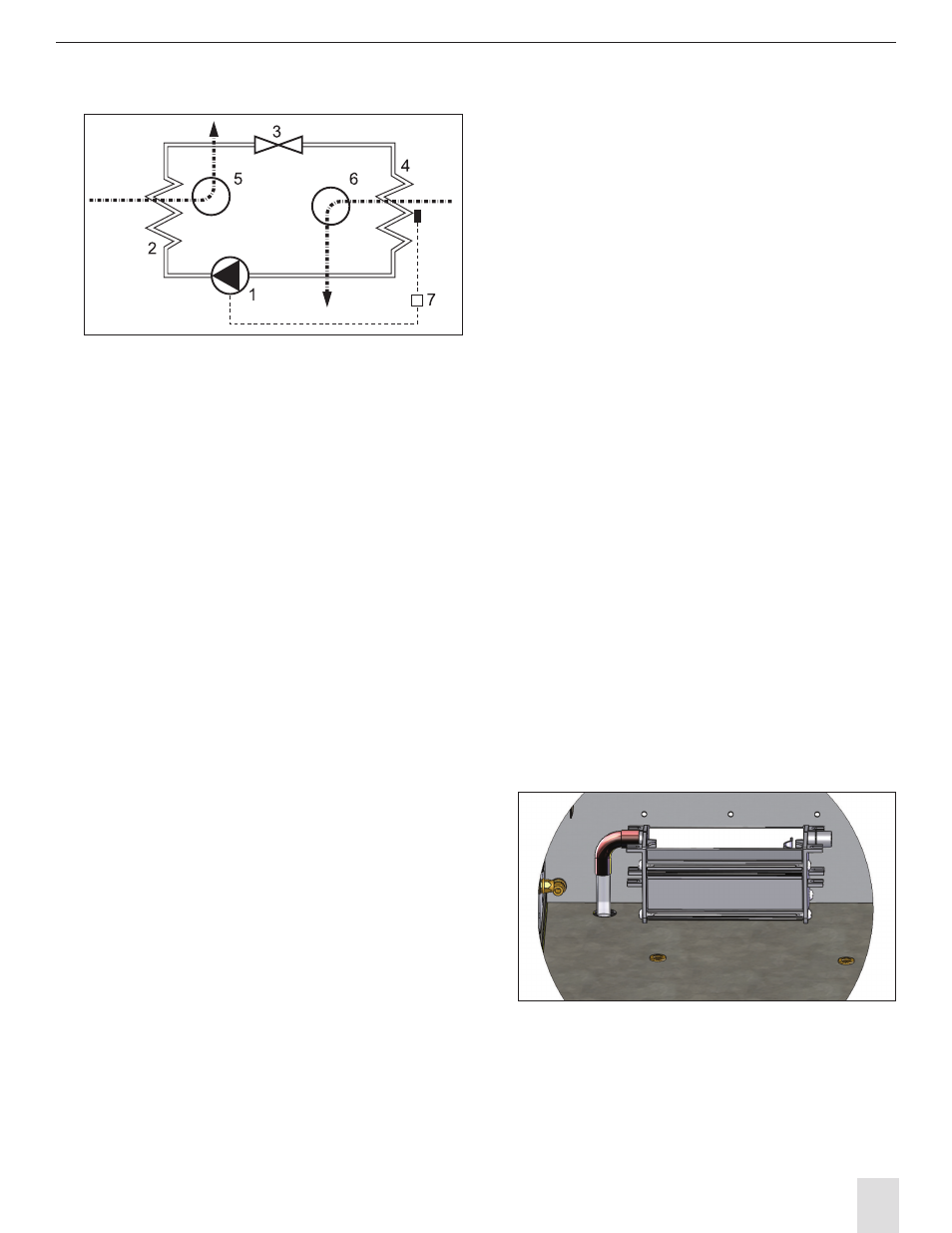

5.2 Theory of Operation

∞

∞

1 Compressor

2 Heat exchanger (condenser)

3 Expansion valve/ capillary line

4 Heat exchanger (evaporator)

5 fan, exterior circulation

6 fan, inner circulation

7 Electronic control system with temperature sensor

The compressor (1) compresses the refrigerant

until it becomes a high pressure gas. During the

compression process, the temperature of the

refrigerant gas increases.

As the refrigerant in the form of a high pressure, high

temperature gas flows through the condenser (2)

the refrigerant cools and condenses as the heat is

dissipated to the ambient (outside of the electrical

panel) air.

This is accomplished by the condenser fan (5) pulling

in ambient air into the housing and then pushes

the ambient air through the fin and coils of the

condenser (2) and back out of the housing and into

the ambient environment at a higher temperature.

As the now liquid refrigerant passes through the

expansion valve (3) the pressure drops and the

refrigerant becomes a liquid / gas mixture.

As the refrigerant in the form of a liquid / gas passes

through the evaporator (4) it absorbs the heat

from air in the electrical panel enclosure while also

dehumidifying it.

This process lowers the temperature of the air in the

electrical panel enclosure

This is accomplished by the evaporator fan (6)

pulling in the hot air from the electrical panel

enclosure and pushes it through the evaporator

(4) and back into the electrical panel enclosure at a

lower temperature.

The cooling unit is electronically controlled. To

accomplish this a temperature sensor monitors the

temperature inside the electrical panel enclosure

and regulates the function of the cooling unit.

The refrigerants used in the cooling unit are non-

combustible and are minimally detrimental to the

atmosphere.

5.3 Condensation Consideration

During operation, the moisture in the air inside of

the electrical panel enclosure condenses on the fins

of the evaporator and is collected as condensate.

In order to avoid any damage to the electrical

panel enclosure contents or to the cooling unit, the

condensate must be removed from the cooling unit.

The condensate is removed as follows: The

condensate drains into a condensate tray located

at the bottom of the cooling unit and is evaporated

into the ambient air by means of an electrical

heating element.

The free discharge of any accumulated condensate

must be provided for to ensure trouble-free

operation of the cooling unit.

The PTC-heater starts heating immediately on the

application of power to the cooling unit. The PTC-

heater is self-controlled and it’s temperature will

vary depending on the level of condensate in the

condensate tray.