Howard HI-102 Overhead Transformer User Manual

Page 27

Document 2.4.95, Revision 0

May, 2013

27

Fluid-Filled Overhead Distribution Transformers

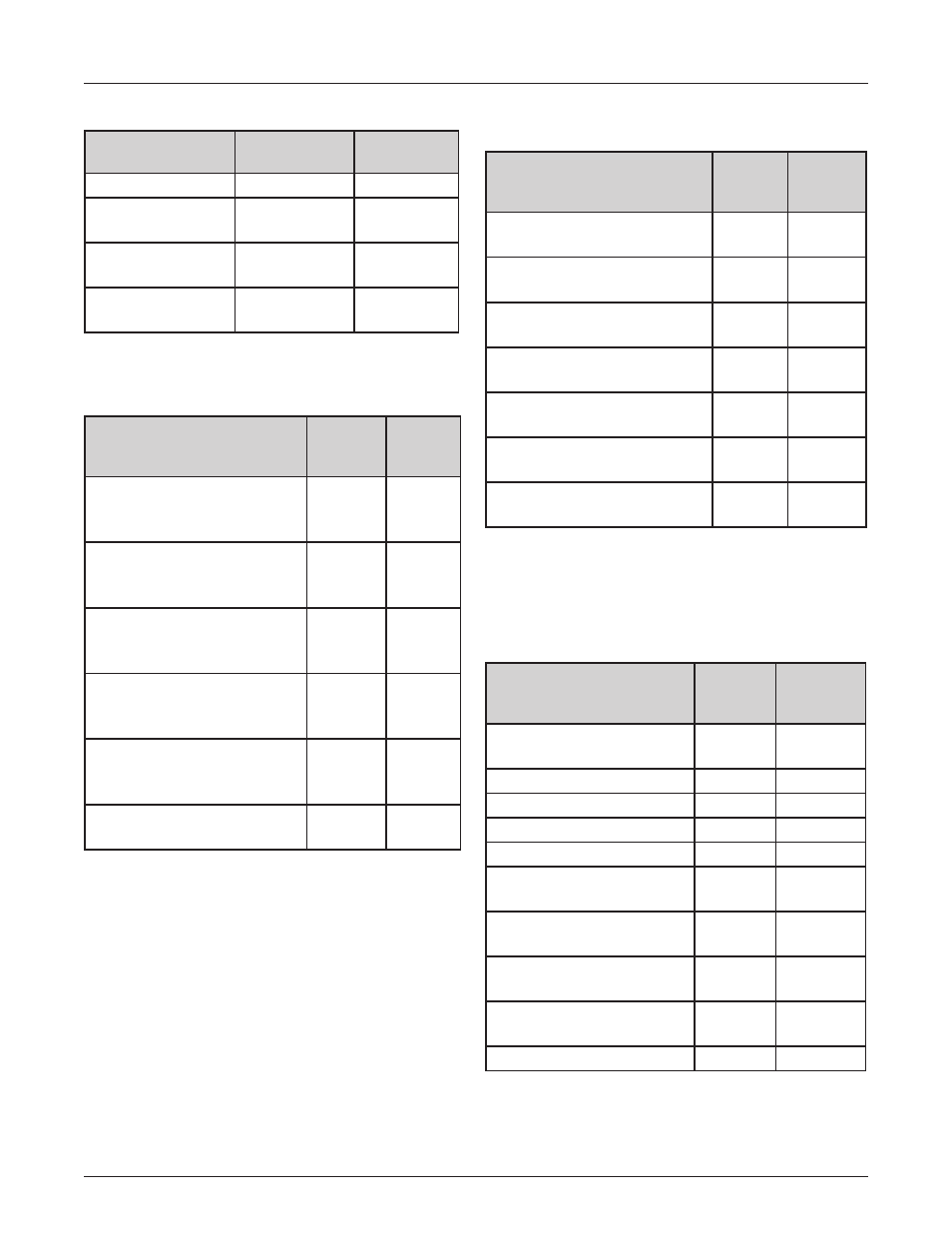

Table 1: Torque Guidelines for External Fasteners

Fastener Type

Nominal Torque

(in-lbs)

Torque Range

(in-lbs)

3/8” bolt

240

220-260

Hand-hole cover

bolt

144

129-158

Fastener Type

Cover band bolt

180

170-185

Surge arrester

mounting bolts

420

372-368

Table 2: Torque Guidelines for External Bushing

Mounting Hardware

Bushing Type

Nominal

Torque

(in-lbs)

Torque

Range

Low-voltage bushing, molded

Tri-Clamp (without clamp

ring), 3/8” mounting studs

60

40-80

Low-voltage bushing, molded

(with clamp ring), 3/8”

mounting studs

120

90-150

Low-voltage bushing, porce-

lain (with clamp ring), 1/2”

mounting studs

80

70-90

High-voltage bushing, mold-

ed Tri-Clamp (without clamp

ring), 3/8” mounting studs

60

40-80

High-voltage bushing,

molded (with clamp ring),

3/8” mounting studs

120

90-150

High-voltage bushing, porce-

lain

80

70-90

When checking tightness of gasketed components, the measured torque

will normally be less than the nominal torque listed in the table above due to

relaxation of the gasket material. Additional tightening of bushing mounting

hardware may cause the component to crack or the gasket to become over-

compressed.

Table 3: Torque Guidelines for External Terminal

Connections

Terminal Type

Nominal

Torque

(in-lbs)

Torque

Range

High-voltage porcelain bush-

ing eye-bolt

210

180-240

High-voltage porcelain bush-

ing end cap

168

156-180

Low-voltage bushing, 5/8”

jam nut

600

480-720

Low-voltage bushing, 1” jam

nut

600

480-720

Low-voltage bushing, 1-1/4”

jam nut

720

600-840

External surge arrester line

lead

180

162-198

External surge arrester

ground lead

180

162-198

When checking tightness of gasketed components, the measured torque

will normally be less than the nominal torque listed in the table above due to

relaxation of the gasket material. Additional tightening of bushing mounting

hardware may cause the component to crack or the gasket to become over-

compressed.

Table 4: Torque Guidelines for Accessories

Component

Nominal

Torque

(in-lbs)

Torque

Range

(in-lbs)

Bushing-mounted weak-

link fuse mounting bolts

85

80-90

Fluid-level sight plug

960

900-1020

Fill plug

960

900-1020

Drain plug

960

900-1020

Drain valve

600

480-720

Automatic pressure relief

device, 1/4” NPT

180

160-200

Automatic pressure relief

device, 1/2” NPT

360

324-396

Neutral strap fastener (at

ground pad)

160

140-180

Series/multiple, delta/wye

or tap switch mounting nut

120

96-144

Ground connector

160

140-180

When checking tightness of gasketed components, the measured torque

will normally be less than the nominal torque listed in the table above due to

relaxation of the gasket material. Additional tightening of bushing mounting

hardware may cause the component to crack or the gasket to become over-

compressed.