Commissioning, operation – WIKA 700.02 User Manual

Page 11

WIKA operating instructions differential pressure gauge with piston

11

2103869.04 12/2012 GB/D/F/E

GB

7. Commissioning, operation

Switch point adjustment

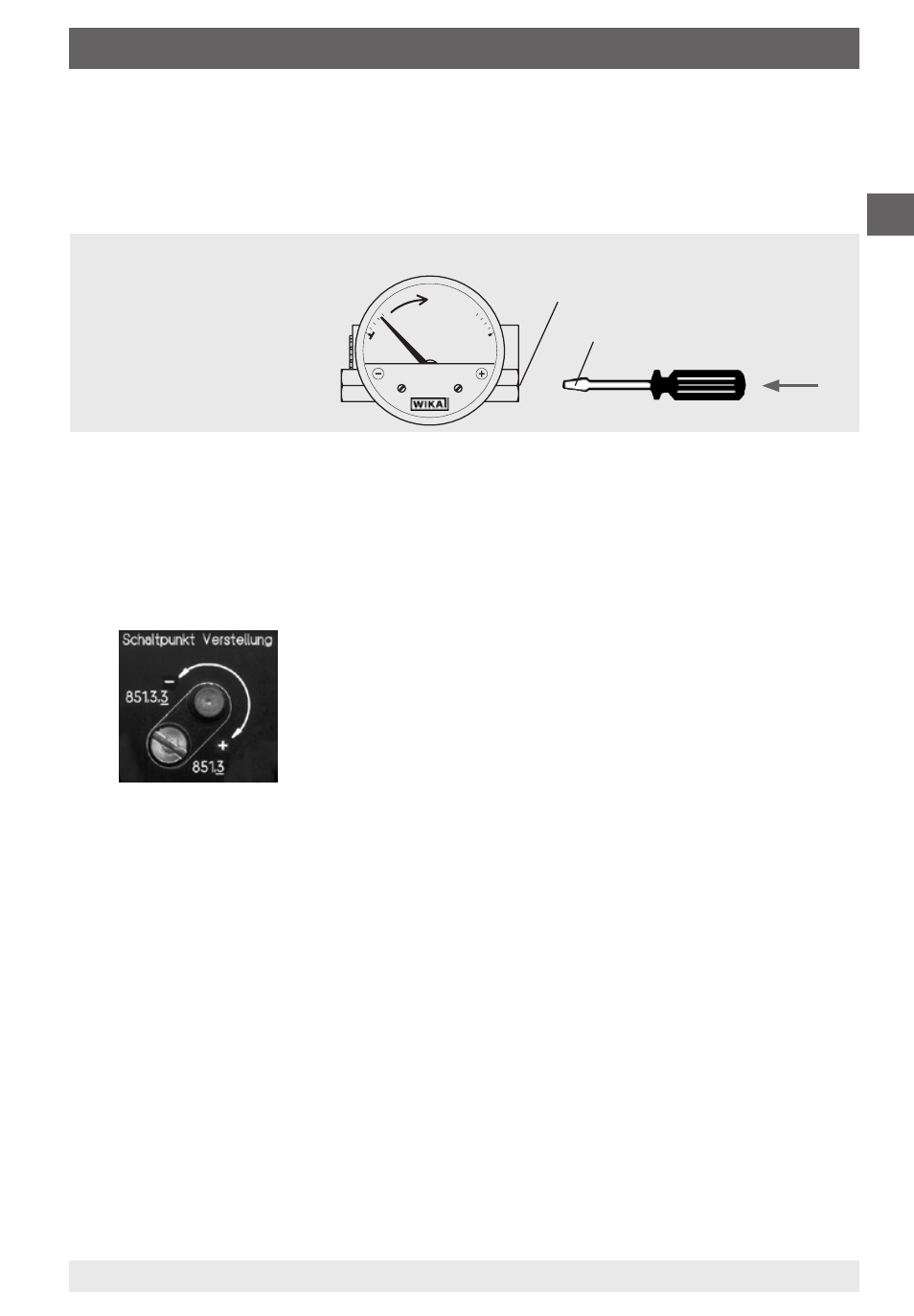

Preference should be given to setting the switch point before installing the

measuring instrument. The necessary test path is generated manually (e.g. by

means of an antimagnetic screwdriver).

Manual test path generation

Plus media chamber

antimagnetic

The switch point can also be set in a pressurised condition after installation. The

switch points are set at the factory when the set points are given.

The switch point is adjusted by turning the contact adjustment screws on the

outside of the reed case.

Anticlockwise rotation:

Switch point can be moved in the direction of the

start of the measuring range

Clockwise rotation:

Switch point can be moved in the direction of the

end of the measuring range

Zero point check

In general, the zero point should only be checked and adjusted at zero pressure.

The system fastening lug on the back of the case can be easily slackened off for

zero point correction of the pressure gauge. Now the zero point can be readjusted

by moving the measuring system to the right or left. After this has been done the

measuring system is to be secured again with the mounting screw (recommended

tightening torque of the mounting screw 1.3 Nm).